Sectional type filter element and engine particle catcher thereof

A particle trap, segmented technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of increasing combustion efficiency, reducing particle capture efficiency, increasing engine exhaust back pressure, etc., to reduce Fuel consumption rate, increased fuel economy, and improved combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

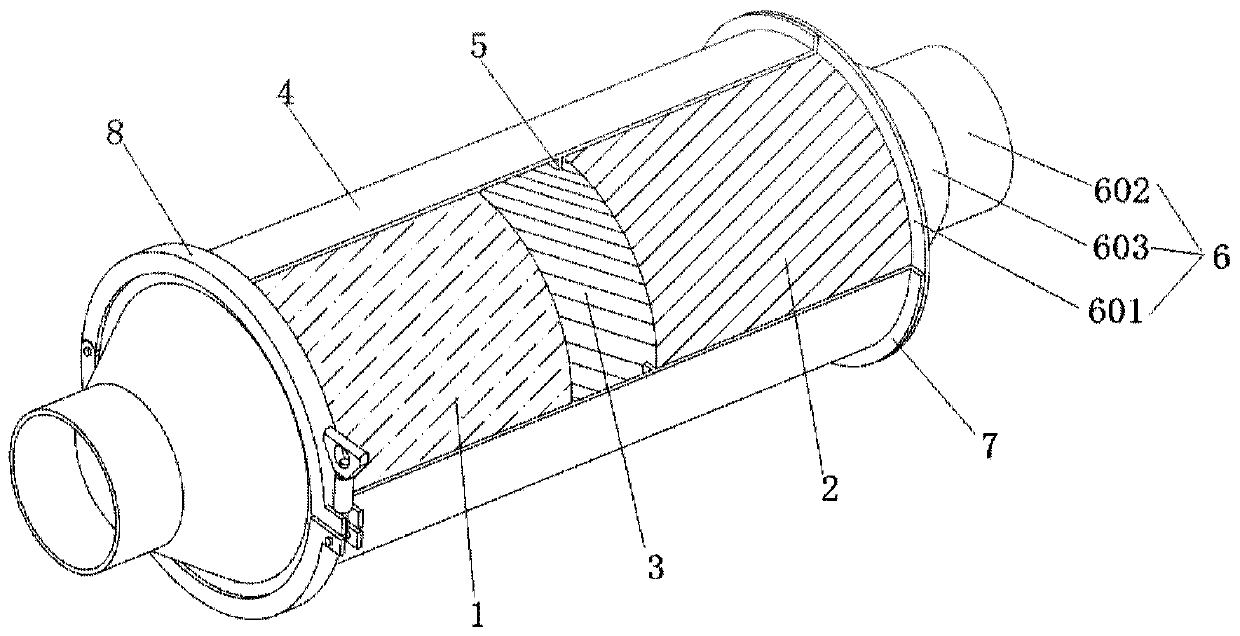

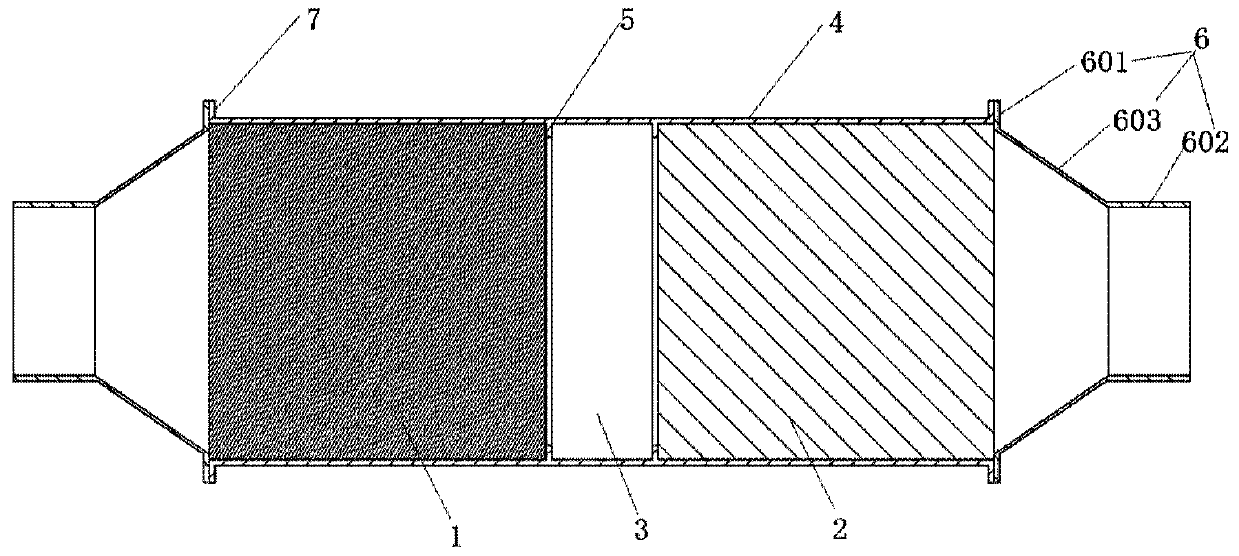

[0049] For Dongfeng Chaoyang Chaochai 4102-CE4M diesel engine, its displacement is 3.865L;

[0050] The total filtration volume of the segmented filter element is 6L; the diameter of each section of the filter element is 150mm, and the length of each section of the filter element is 170mm, a total of 340mm; the turbulence spacer layer 3 is 60mm;

[0051] The first filter core body 1 is a metal foam material filter core body, and the average pore diameter of the first filter core body 1 is 0.3 mm; the second filter core body 2 is a cordierite wall-flow filter core body, and the average pore diameter of the second filter core body is 0.3 mm. 0.02mm;

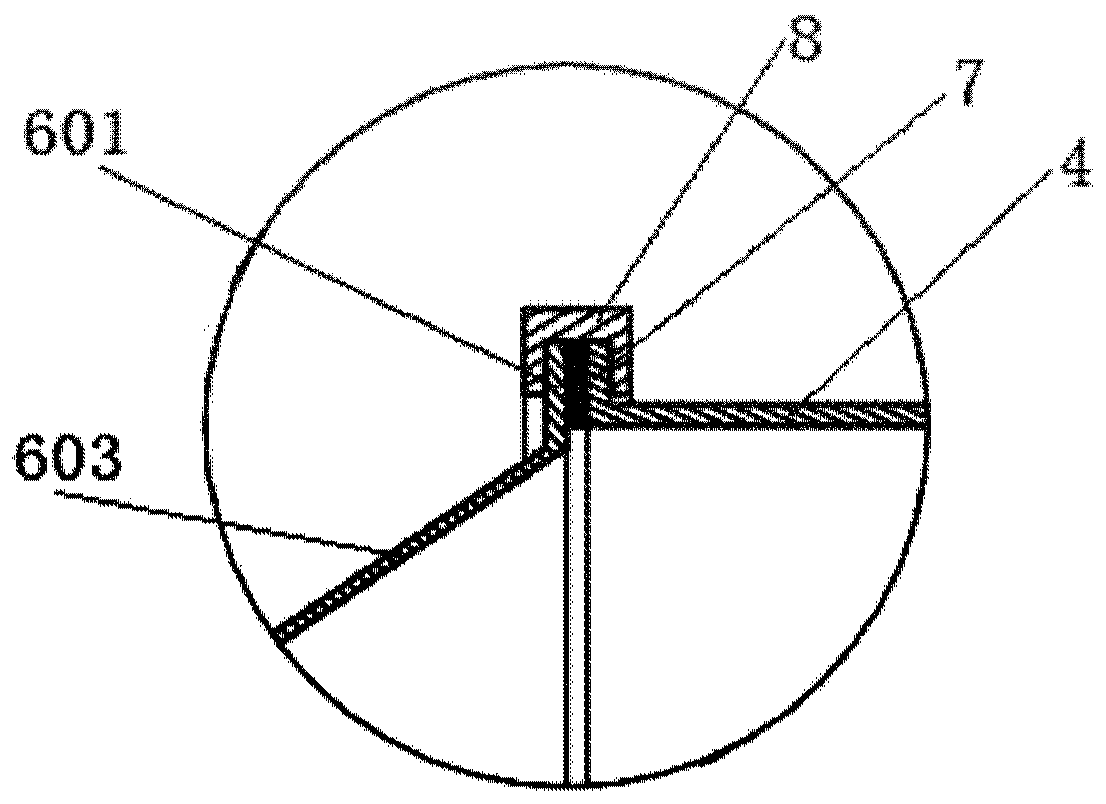

[0052] The radial width of the fixed ring 5 is 5 mm, and the outer edge of the fixed ring 5 is welded to the inner wall of the housing 4 .

[0053] Installation method: set the first filter core body 1 in the housing 4, between the fixing ring 5 and the airway end cover 6; set the second filter core body 2 in the housing 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com