A kind of preparation method of bacterial cellulose-carbon nanotube/polyaniline composite microfiber and micro supercapacitor

A technology of bacterial cellulose and supercapacitors, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of insoluble in organic solvents, poor conductivity, etc. The effect of improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

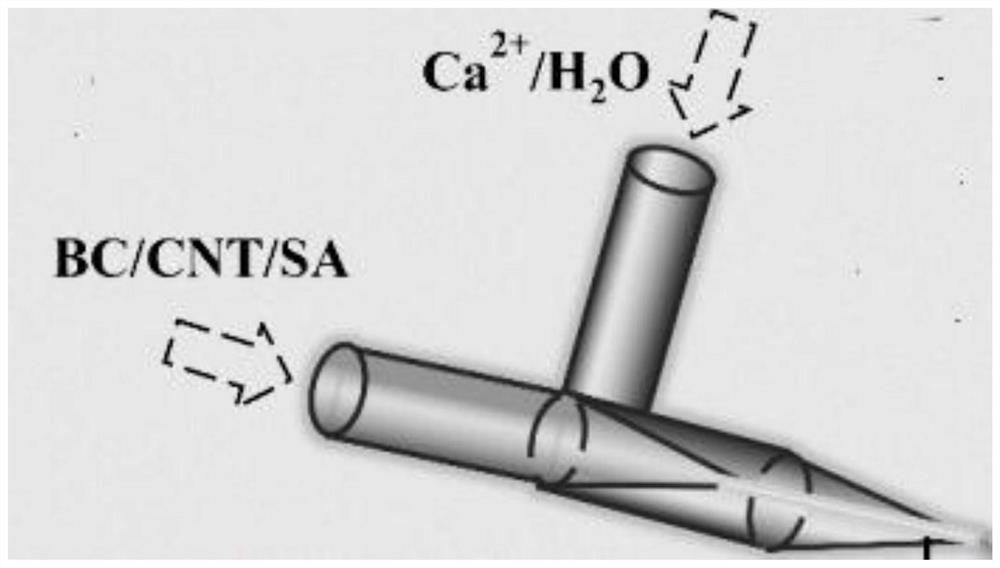

[0052] Reaction microchannel: a core cavity is built into the tube cavity, and a tube cavity outside the core cavity is a sheath cavity; the entrances of the core cavity and the sheath cavity are respectively connected to the core tube and the sheath tube.

[0053] self made:

[0054]Step 1: Insert a plastic steel needle (core lumen) with an inner diameter of 0.61mm coaxially into another plastic steel needle (lumen) with an inner diameter of 0.84mm; a third plastic steel needle (sheath tube) with an inner diameter of 0.61mm ) into the 0.84mm needle from the side, so that the gap (sheath cavity) between the third needle and the first two needles communicates;

[0055] Step 2: After fixing the joint with α-ethyl cyanoacrylate as an instant adhesive, a Y-shaped microchannel was established. Raw materials enter from two inlets and then go out from the same outlet, forming a core-shell structure.

[0056] Example:

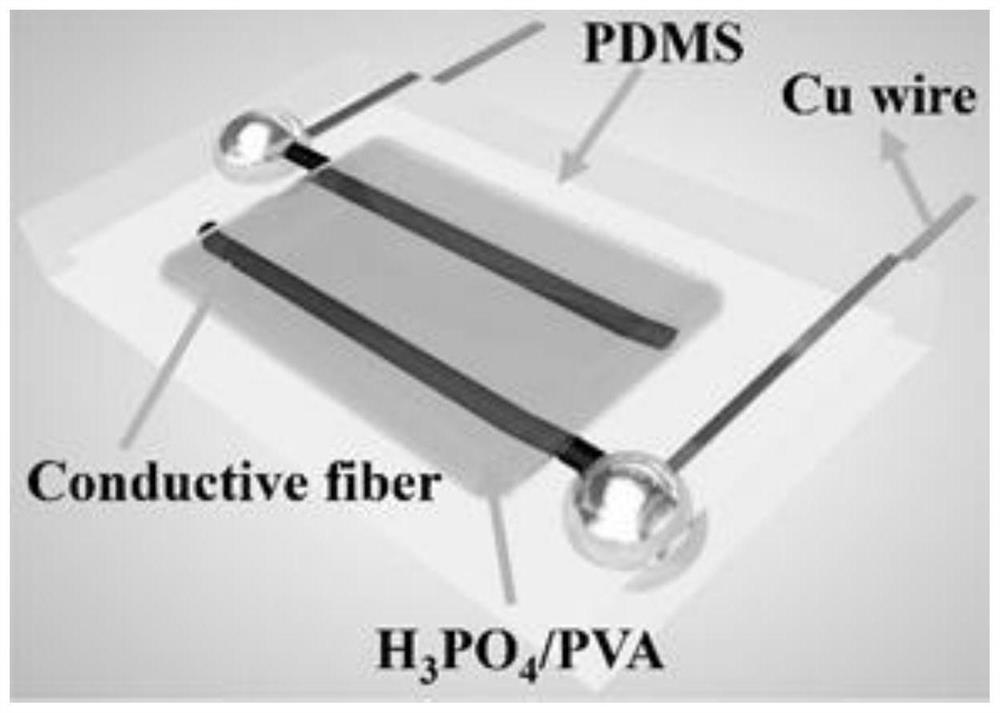

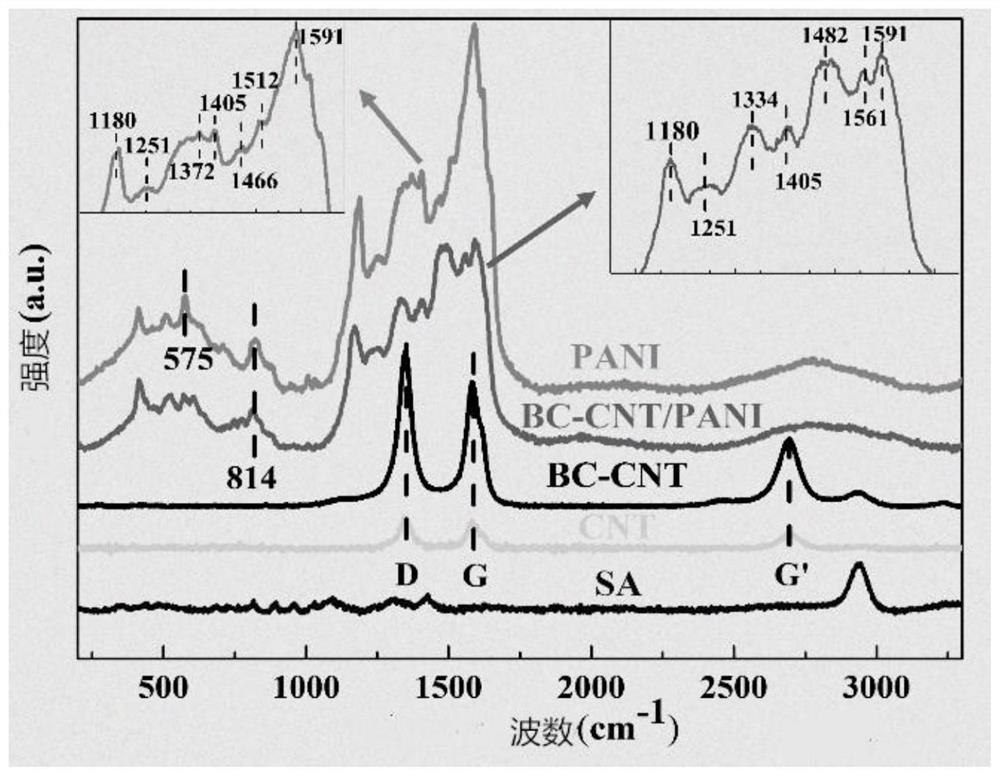

[0057] A bacterial cellulose-carbon nanotube / polyaniline compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com