Ceramic antenna feed hole insulation structure

A technology of insulating structure and ceramic antenna, which is applied in the direction of antenna grounding switch structure connection, antenna grounding device, radiating element structure and other directions, which can solve the problem that the circuit board area becomes larger, occupies space, and cannot reach the 50 ohm impedance characteristic of copper coaxial cable. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

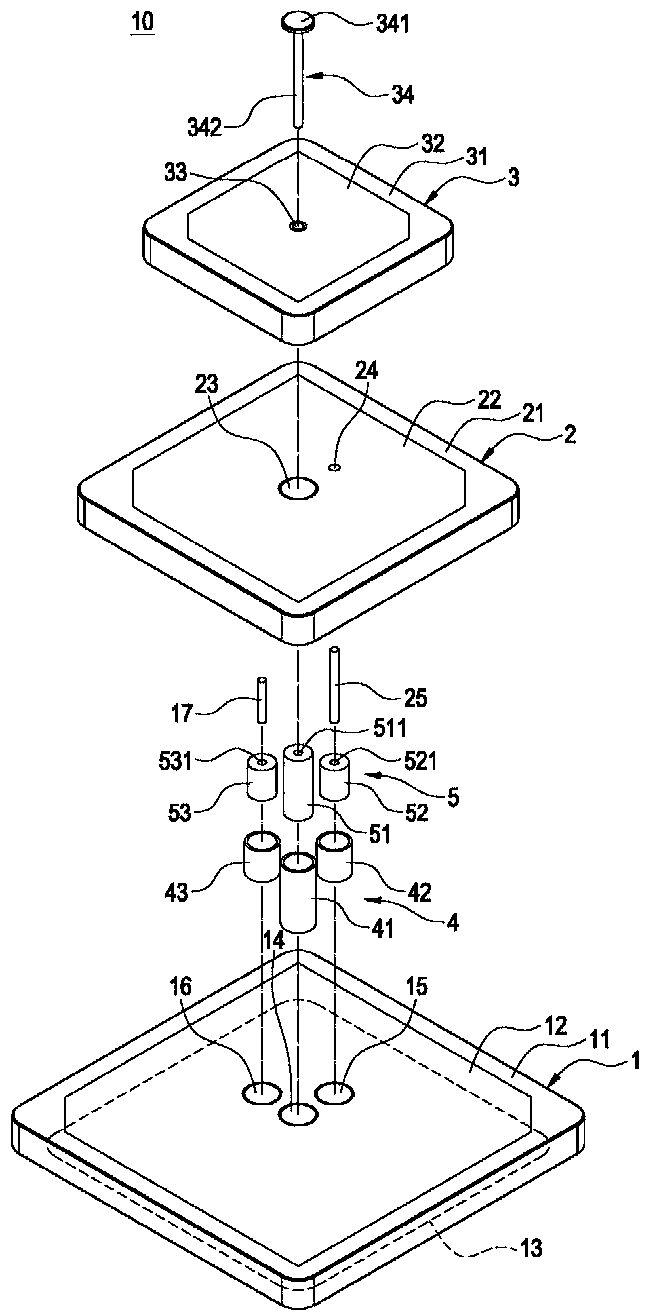

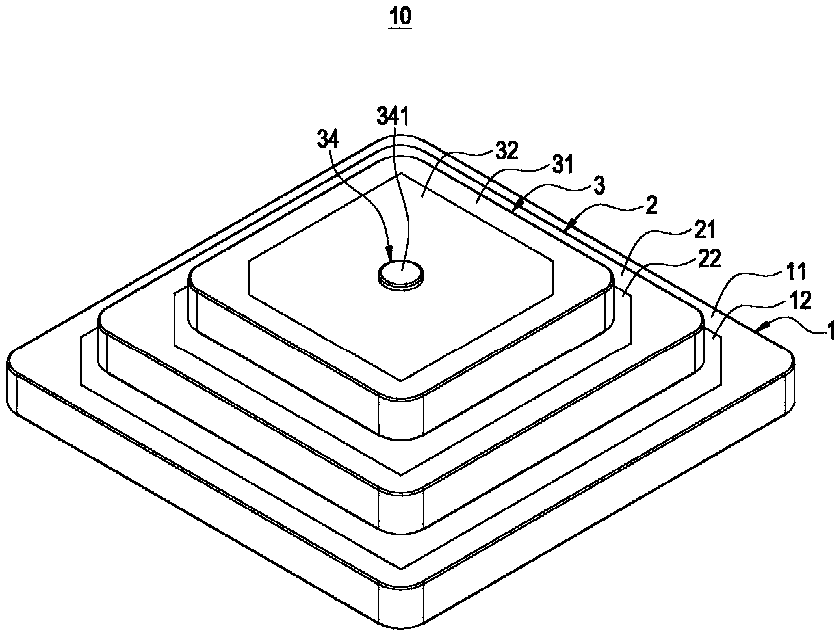

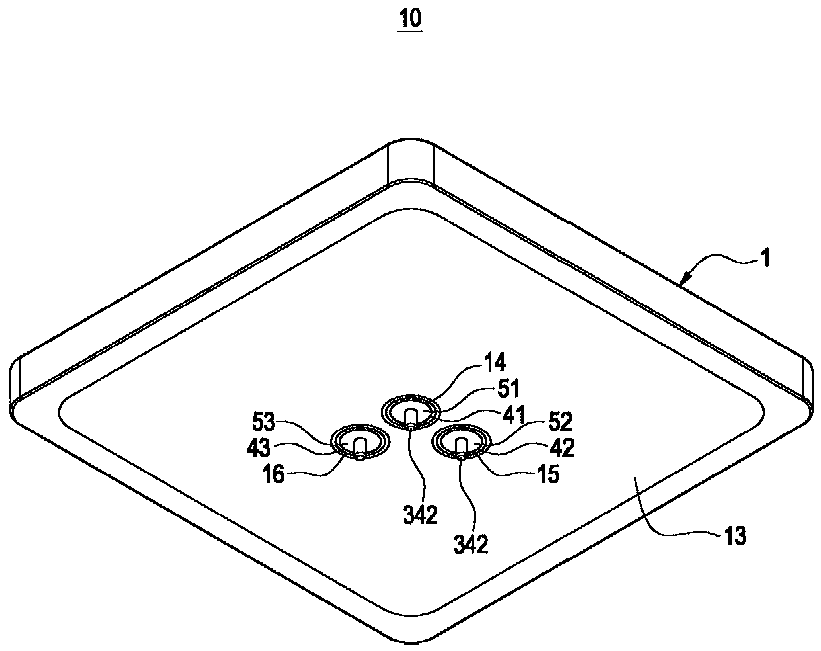

[0022] Relevant technical content and detailed description of the present invention, now coordinate drawing description as follows:

[0023] see Figures 1 to 4 As shown, it is a schematic view of the insulation structure line decomposition, combination bottom view and bottom surface of the ceramic antenna feeding hole of the present invention. As shown in the figure: the ceramic antenna feeding hole insulation structure of the present invention includes: a first antenna 1 , a second antenna 2 , a third antenna 3 , a conductive layer group 4 and a dielectric layer group 5 . Wherein, the first antenna 1, the second antenna 2 and the third antenna 3 are stacked into a three-stacked antenna 10 in an approximate cone shape, and the conductive layer group 4 and the dielectric layer group 5 are arranged on the first antenna 1 and the signal feed-in path of the second antenna 2, the signal feed-in path can achieve impedance matching such as the 50 ohm characteristic of a copper cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com