Cell Encapsulation Devices Containing Structural Spacers

A technology of cell encapsulation and spacer, which is applied in the direction of cell encapsulation, drug devices, microorganisms, etc., and can solve the problems of discontinuity, interruption, and reduction of internal volume on the external blood vessel formation surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

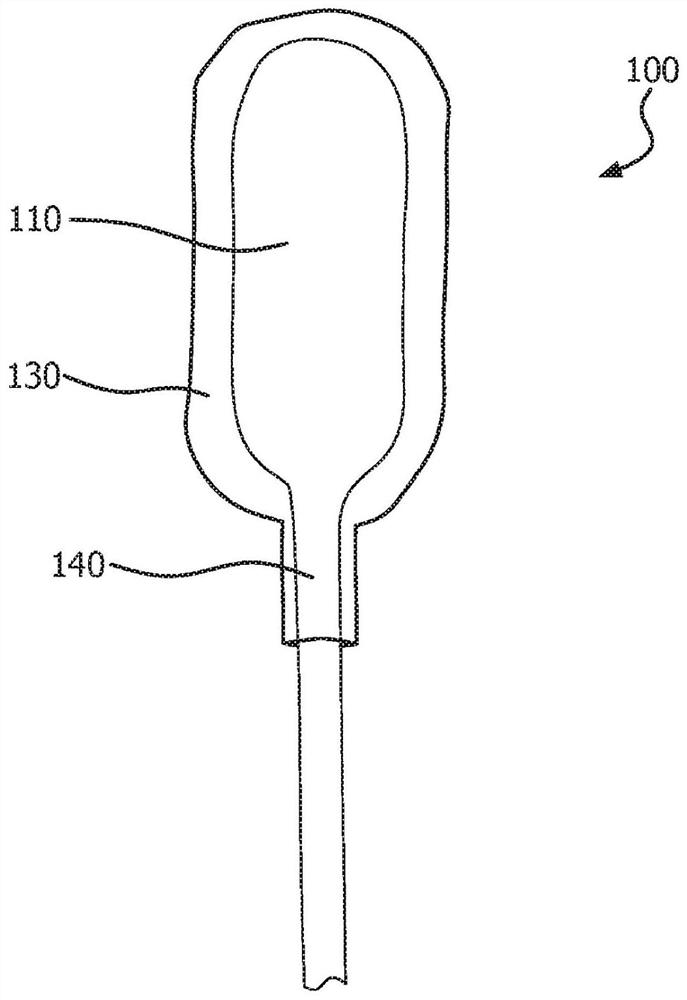

[0111] Obtain an ePTFE membrane with two cell-retaining (tight) layers separated by a vessel-forming (open) layer, as Figure 11 shown. A porous structural spacer formed of ePTFE connects the outer retention layer and forms a storage space for accommodating the battery therein. Two sheets of fluorinated ethylene propylene (FEP) film, each 4 mils thick (about 100 microns), were cut to form the perimeter seal of the cell encapsulation device. The cut FEP sheets were then stacked and aligned on the outer cell holding surface of a 1" x 2" (approximately 2.5 cm x 5 cm) sample of ePTFE membrane. A small area around the perimeter of the strip was protected with Kapton tape on both sides so that the perimeter could be left unbonded to allow access to the interior chamber.

[0112] The ePTFE / FEP stack was then compressed through a silicone die at a pressure of 90 psi (approximately 6.2 bar or 620.5 kPa) and heated with a pulsed heating tape at a temperature of 375°C for 30 seconds to...

Embodiment 2

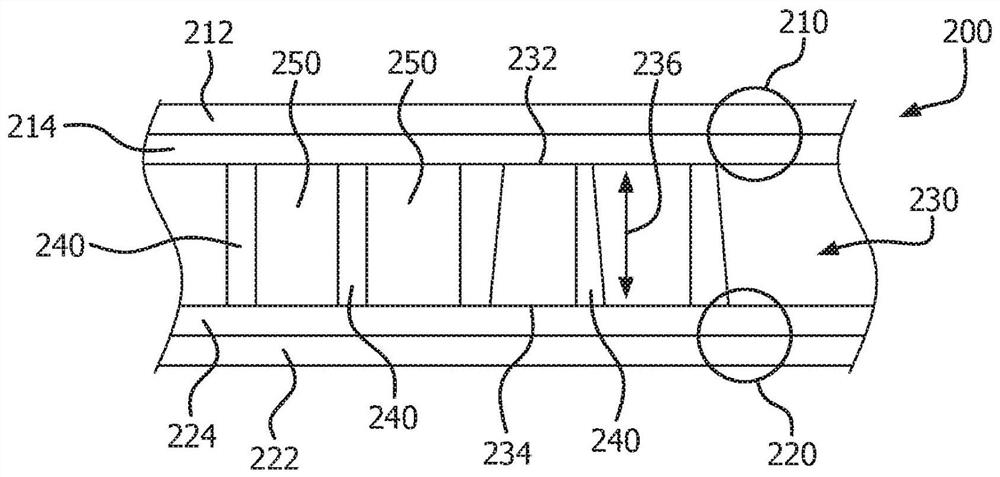

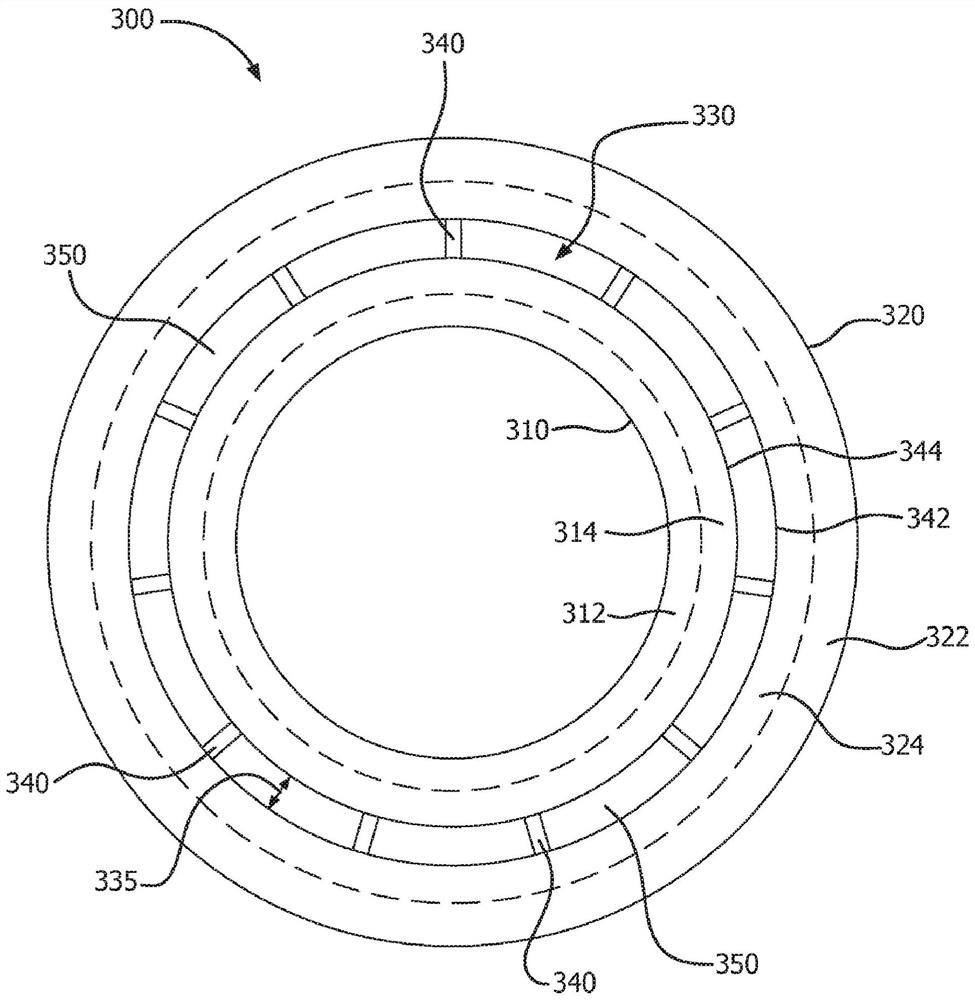

[0114] In this example, thermoplastic polymers are used to create three-dimensional structural supports with patterned geometries. The cell-retaining ePTFE membrane is constrained in the ring. A patterned grid was placed on the surface of the ePTFE membrane to create a mask. The open areas of the grid translate into covered areas created by thermoplastic structural supports. Fluorinated ethylene propylene (FEP) powder was uniformly applied to the mask-covered confinement film by using a metal screen. Metal sieves with 150 micron and 710 micron openings were used. The FEP coating powder was melted and cured by placing the coated ePTFE membrane in an oven at 300°C for 10 minutes. Then remove the mask. The three-dimensional structural support remains on the surface of the cell retention membrane.

Embodiment 3

[0116] Samples A, B, C, and D were cut, each approximately 1" x 2" (approximately 2.5 cm x 5 cm), from a three-layer ePTFE composite comprising an inner layer with structural spacers and as shown in Table 1 as defined by the two outer layers. The inner layer is located between the two outer layers (ie, one on each side of the inner layer). Membrane properties are listed in Table 1.

[0117] Table 1

[0118]

[0119] Die sections of 4 mil (about 100 micrometers) thick fluorinated ethylene propylene (FEP) films were placed in parallel and adjacent to the outer layers of the film samples to form stacks. Each stack was then aligned with the device geometry listed on the silicone template and pulse thermally bonded. The perimeter seal was formed by compressing the material stack along the desired sealing geometry at 90 psi (about 6.2 bar or 620.5 kPa) and heating at 375°C for 30 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com