Hydroformylation method, reaction device and reaction system using same

A reaction device, the technology of chemical reaction, applied in the field of reaction system, hydroformylation reaction device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

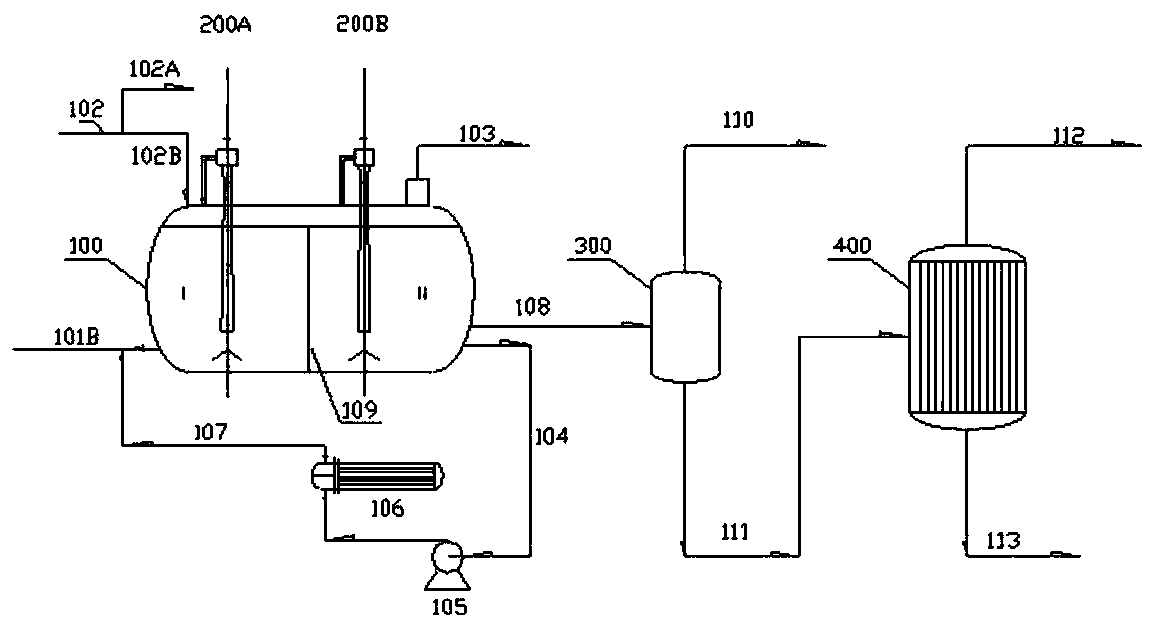

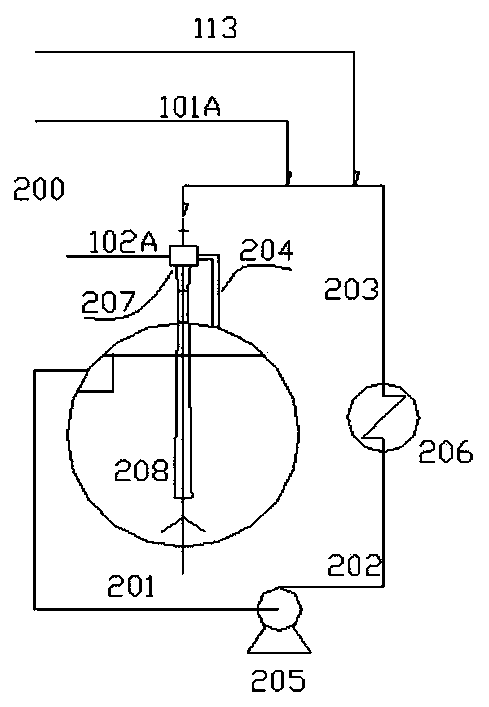

[0080] use figure 2 Shown two-stage jet flow reactor, selects propylene to be the olefin raw material to test, catalyst rhodium concentration 80ppm, ligand is the composition of three (o-methylphenyl) phosphorus L0 and L4, wherein the mole of Rh:L0:L4 The ratio is 1:10:4, the temperature of the reactor is maintained at 90°C, and the reaction pressure is at 1.6MPa. The effective reaction liquid volume of the reaction kettle 100 is 10L, which is divided into two cavities of equal volume, and an injector 200A and 200B are respectively arranged on the top of each cavity. The diameter of the spray expansion tube is 14mm, and the length of the spray tube is 400mm.

[0081] In this embodiment, the propylene feed 101A is 1.6kg / h, 101B is 0.4kg / h, the synthesis gas 102A is 1720NL / h, the synthesis gas 102B is 420NL / h, the volume flow rate of the circulation 203 is 150L / h, and the gas circulation The quantities are all displayed as 175L / h. The output rate of butyraldehyde is 3.40kg / h...

Embodiment 2

[0084] use figure 2 Shown two-stage jet flow reactor, selects propylene to be the olefin raw material to test, catalyst rhodium concentration 80ppm, ligand is the composition of three (o-methylphenyl) phosphorus L0 and L5, wherein the mole of Rh:L0:L5 The ratio is 1:10:4, the temperature of the reactor is maintained at 90°C, and the reaction pressure is at 1.6MPa. The effective reaction liquid volume of the reaction kettle 100 is 10L, which is divided into two cavities of equal volume, and an injector 200A and 200B are respectively arranged on the top of each cavity. The diameter of the spray expansion tube is 14mm, and the length of the spray tube is 400mm.

[0085] In this embodiment, the propylene feed 101A is 1.6kg / h, 101B is 0.4kg / h, the synthesis gas 102A is 1720NL / h, the synthesis gas 102B is 420NL / h, the volume flow rate of the circulation 203 is 150L / h, and the gas circulation The quantities are all displayed as 175L / h. The output rate of butyraldehyde is 3.41kg / h...

Embodiment 3

[0087] use figure 2 Shown two-stage jet flow reactor, select propylene to be the olefin raw material to test, catalyst rhodium concentration 80ppm, ligand is the composition of three (o-methylphenyl) phosphorus L0 and monophosphite L7, wherein Rh:L0 The molar ratio of :L7 is 1:10:4, the temperature of the reactor is maintained at 90°C, and the reaction pressure is at 1.6MPa. The effective reaction liquid volume of the reaction kettle 100 is 10L, which is divided into two cavities of equal volume, and an injector 200A and 200B are respectively arranged on the top of each cavity. The diameter of the spray expansion tube is 14mm, and the length of the spray tube is 400mm.

[0088] In this embodiment, the propylene feed 101A is 1.6kg / h, 101B is 0.4kg / h, the synthesis gas 102A is 1720NL / h, the synthesis gas 102B is 420NL / h, the volume flow rate of the circulation 203 is 150L / h, and the gas circulation The quantities are all displayed as 175L / h. The output rate of butyraldehyde ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com