Multiple thin wall titanium tube and steel tube sheet hole simultaneous explosive welding composite tube sheet and method

A technology of explosive welding and composite pipe, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of difficult control of explosive welding quality, and achieve the effects of improving service life, ensuring safety, and high welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

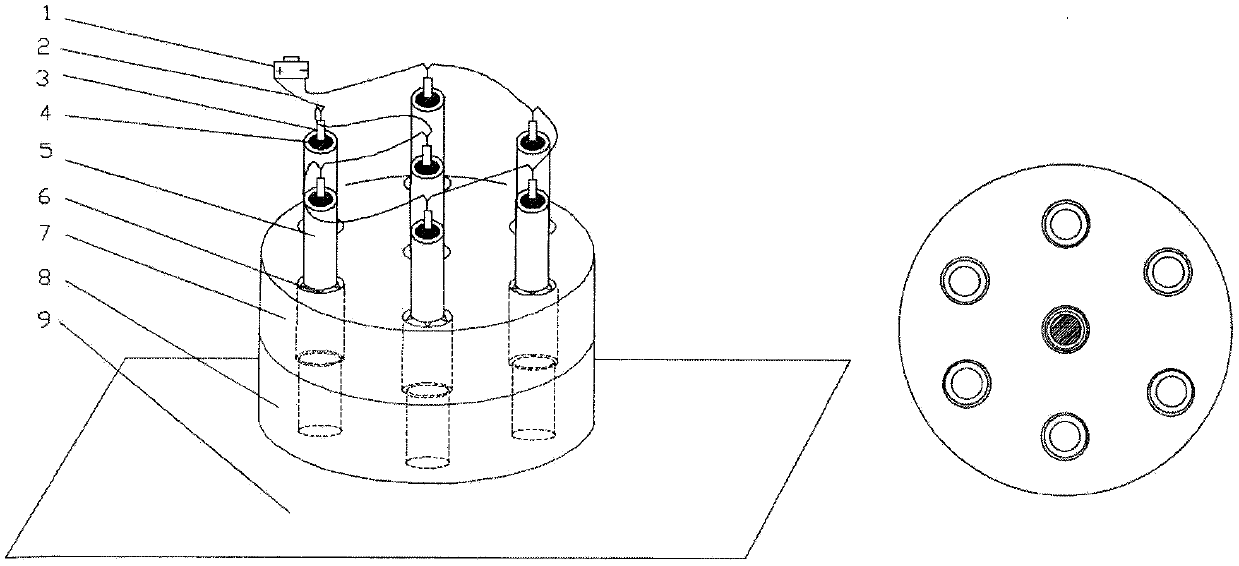

[0022] Such as figure 1 shown.

[0023] A method for synchronous explosive welding of multiple thin-walled titanium tubes and steel plates, comprising the following steps:

[0024] First, the thin-walled titanium tube is loaded with an explosive with an optimized formula, the wall thickness of the thin-walled titanium tube is 1-2 mm, and the explosive with an optimized formula is composed of 60-70% explosive and the remaining A certain amount of auxiliary materials composed of salt, perlite and sawdust, the weight ratio of the auxiliary material salt, perlite and sawdust is 2: 1: 1;

[0025] In order to achieve the explosive welding of titanium tubes with a wall thickness of only 1-2mm, the explosives used should be small in intensity, and their detonation velocity must be controlled within the critical detonation velocity, so that the pressure of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com