Movement decoupling hydraulic driving three-degree-of-freedom spherical wrist

A degree of freedom and motion technology, applied in the field of robotics, can solve the problems of limited attitude adjustment ability and precise positioning ability, large wrist weight, long wrist transmission chain, etc., to achieve strong attitude ability, compact structure and high power density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

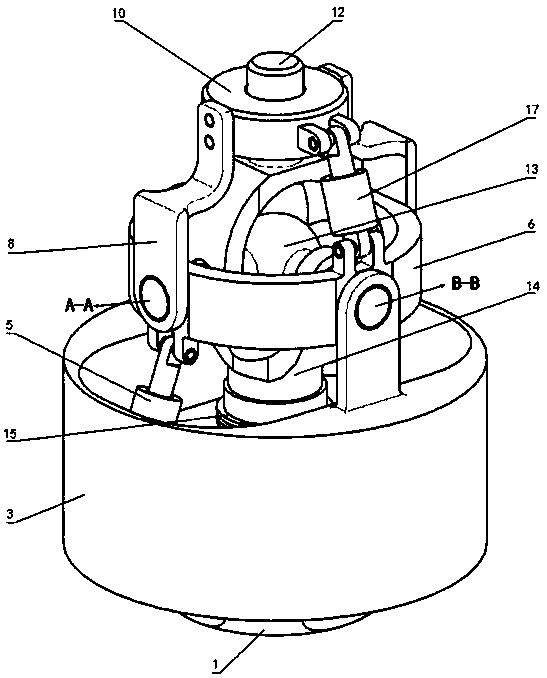

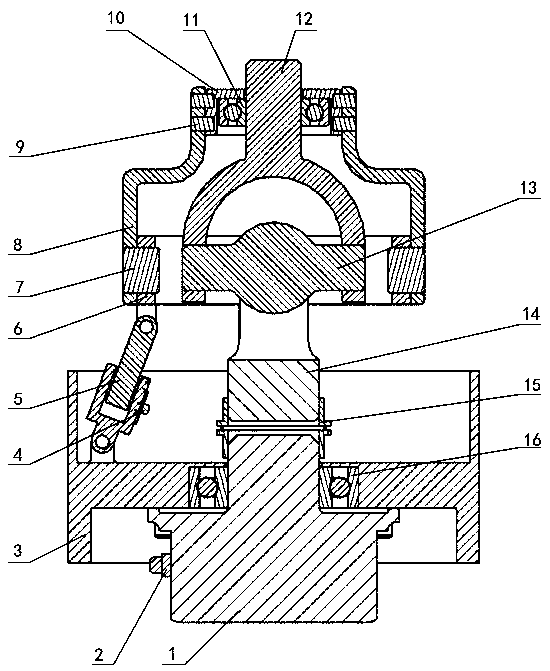

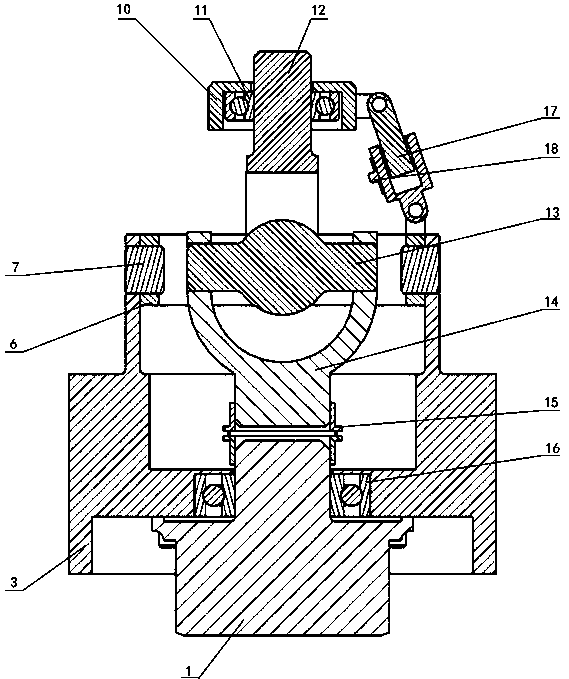

[0024] Attached below figure 1 ~ attached image 3To further illustrate the embodiment of the present invention, a hydraulically driven three-degree-of-freedom spherical wrist with motion decoupling is composed of an autorotation hydraulic motor 1, an angle sensor 2, a frame 3, a first displacement sensor 4, and a pitch hydraulic cylinder 5 , Pitch ring 6, first connecting screw 7, connecting rib 8, second connecting screw 9, side swing end cover 10, first bearing 11, second transmission shaft 12, universal joint 13, first transmission shaft 14. Coupling 15, second bearing 16, side swing hydraulic cylinder 17, and second displacement sensor 18, wherein the bottom of the frame 3 is provided with a cylindrical groove for placing the self-rotating hydraulic motor 1, and the middle is provided with a second bearing 16 The cylindrical groove and the round hole for the motor shaft to protrude. The top is provided with an auxiliary rib plate that is connected to the pitch ring 6 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com