An environmentally friendly and stable surface-impregnated wood and its preparation method

A technology of impregnating wood and stable type is applied in the field of environment-friendly and stable wood and its preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

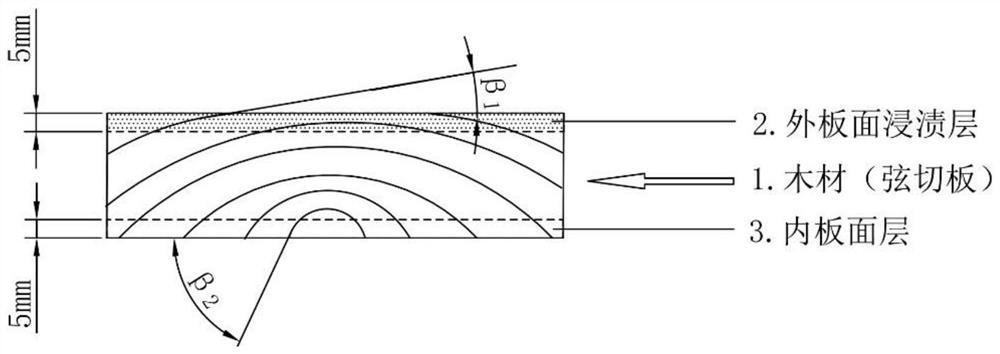

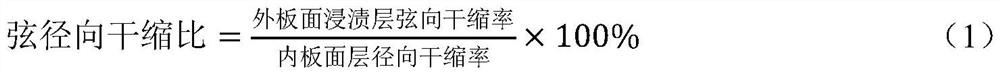

[0033] In this embodiment, poplar is dipped in beeswax on the surface, and the poplar used is a string-cut board, β 1 is 20°, β 2 It is 65°, the chord radial shrinkage ratio is 1.88, and the initial moisture content is 8%.

[0034] 1. Wax melting treatment: heat the solid beeswax to the target temperature of 45°C for 25 minutes.

[0035] 2. Wax dipping treatment: immerse the surface layer of the outer panel of poplar wood into liquid beeswax to a depth of 2 mm for 2 minutes to obtain an impregnated layer on the outer panel surface, such as figure 1 shown.

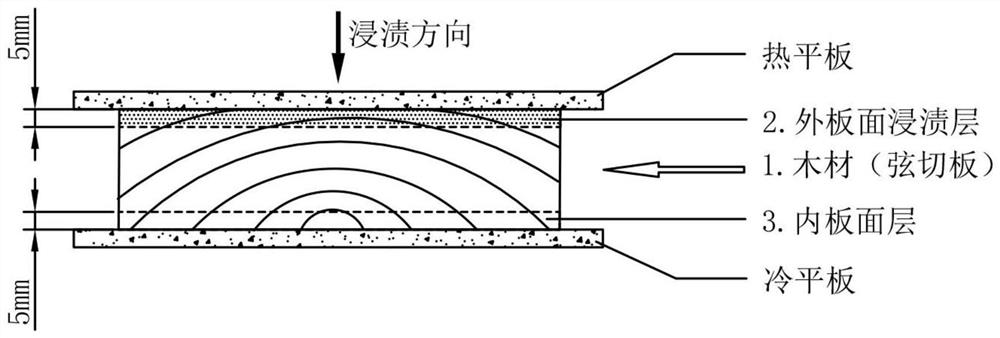

[0036] 3. Waxing treatment: raise the temperature of the hot plate to the target temperature of 120°C, and keep the temperature of the cold plate at 20°C. Place the inner surface layer of the wood treated in step 2 on the cold plate, close the hot plate, and apply a pressure of 0.2MPa to ensure that the hot plate and the impregnated layer of the outer wood surface are closely attached during the whole process, and the ho...

Embodiment 2

[0042] In this embodiment, poplar is dipped in beeswax on the surface, and the poplar used is a string-cut board, β 1 is 25°, β 2 It is 67°, the chord radial shrinkage ratio is 1.93, and the initial moisture content is 10%.

[0043] 1. Wax melting treatment: heat the solid beeswax to the target temperature of 65°C for 30 minutes.

[0044] 2. Wax dipping treatment: immerse the surface layer of the outer panel of poplar wood into the liquid beeswax to a depth of 3mm, and soak for 3 minutes to obtain an impregnated layer on the surface of the outer panel, such as figure 1 shown.

[0045] 3. Waxing treatment: raise the temperature of the hot plate to the target temperature of 140°C, and keep the temperature of the cold plate at 25°C. Place the inner surface layer of the wood treated in step 2 on the cold plate, close the hot plate, and apply a pressure of 0.2 MPa to ensure that the hot plate and the impregnated layer of the outer wood surface are closely attached during the who...

Embodiment 3

[0050] In this embodiment, the surface layer of rubber wood is impregnated with beeswax, and the rubber wood used is a string cut board, β 1 is 28°, β 2 It is 75°, the shrinkage ratio of chord and radial direction is 2.16, and the initial moisture content is 12%.

[0051] 1. Wax melting treatment: heat the solid beeswax to the target temperature of 70°C for 35 minutes.

[0052] 2. Wax dipping treatment: immerse the surface layer of the outer panel of poplar wood into liquid beeswax to a depth of 4 mm, and soak for 5 minutes to obtain an impregnated layer on the surface of the outer panel, such as figure 1 shown.

[0053] 3. Waxing treatment: raise the temperature of the hot plate to the target temperature of 150°C, and keep the temperature of the cold plate at 30°C. Place the inner surface layer of the wood treated in step 2 on the cold plate, close the hot plate, and apply a pressure of 0.2 MPa to ensure that the hot plate and the impregnated layer of the outer wood surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com