A kind of spinning equipment and spinning method of 1313 yarn

A technology of equipment and yarn, applied in the field of spinning equipment of 1313 yarn, can solve the problems of poor electrostatic removal effect and easy damage to product quality, etc., and achieve the effect of improving the coil winding, improving the static electricity phenomenon and increasing the friction force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

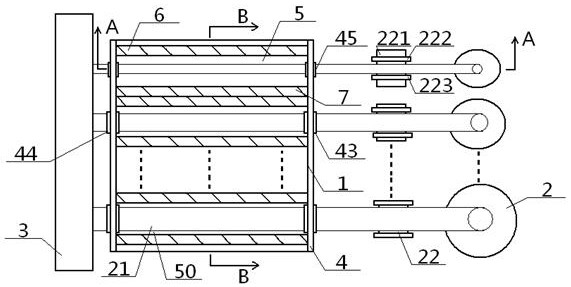

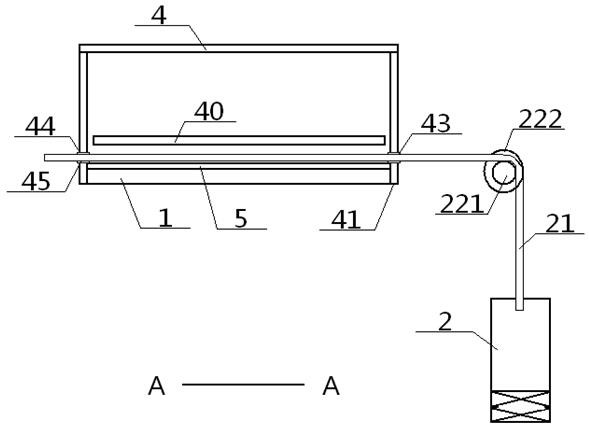

[0057] see figure 1 - Figure 5 , a kind of spinning equipment of 1313 yarns, comprising a guide platform 1, a plurality of sliver cans 2, and a guide wheel 22, the guide wheels 22 correspond to the sliver cans 2 one by one, and the sliver cans 2 There is a raw sliver 21 inside, and the top of the raw sliver 21 passes through the guide wheel 22 and the guide platform 1 in sequence and then extends to the inside of the drafting device 3; the spinning equipment also includes a box with one-way opening downwards Cover 4, the bottom of the box cover 4 is provided with a cover bottom opening 41, and the inside of the cover bottom opening 41 is embedded with a guide strip platform 1, and the guide strip platform 1 includes a plurality of metal plates 5 arranged side by side, each metal plate 5 is all correspondingly provided with a charging plate 40, the metal plate 5, the charging plate 40, the raw sliver 21, and the guide wheel 22 are arranged in one-to-one correspondence, and al...

Embodiment 2

[0060] Basic content is the same as embodiment 1, the difference is:

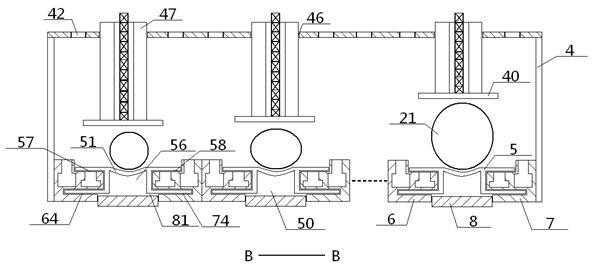

[0061] The top surface of described box cover 4 is provided with a plurality of suction ports 42 and installation port 46, and a vertical movable arm 47 is all correspondingly provided with in each installation port 46, and the bottom end of each vertical movable arm 47 is connected with it. The back side of a corresponding charging plate 40 is connected, and the vertical movable arm 47, the charging plate 40, and the metal plate 5 are sequentially arranged from top to bottom.

Embodiment 3

[0063] Basic content is the same as embodiment 1, the difference is:

[0064] The strip guide platform 1 includes a plurality of strip guide units 50 arranged side by side, and each strip guide unit 50 corresponds to a raw strip 21; the strip guide unit 50 includes a metal plate 5, a left spacer 6 and a right spacer 7. The metal plate 5 includes a top supporting plate 51, a left vertical plate 52, a right vertical plate 53, a left horizontal plate 54 and a right horizontal plate 55, and a charging plate 40 is correspondingly arranged directly above the top supporting plate 51, The bottom surface of the top supporting plate 51 is vertically connected with the tops of the left vertical board 52 and the right vertical board 53, the bottom end of the left vertical board 52 is vertically connected with the inner end of the left horizontal board 54, and the bottom end of the right vertical board 53 is connected with the right horizontal board. The inner ends of 55 are vertically con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com