Seamless expansion joint structure

An expansion joint and seamless technology, applied in the field of bridge expansion joints, can solve the problems of steel expansion joints such as water leakage, poor driving smoothness, and high maintenance costs, and achieve the effects of improving driving comfort, preventing cracking, and high aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

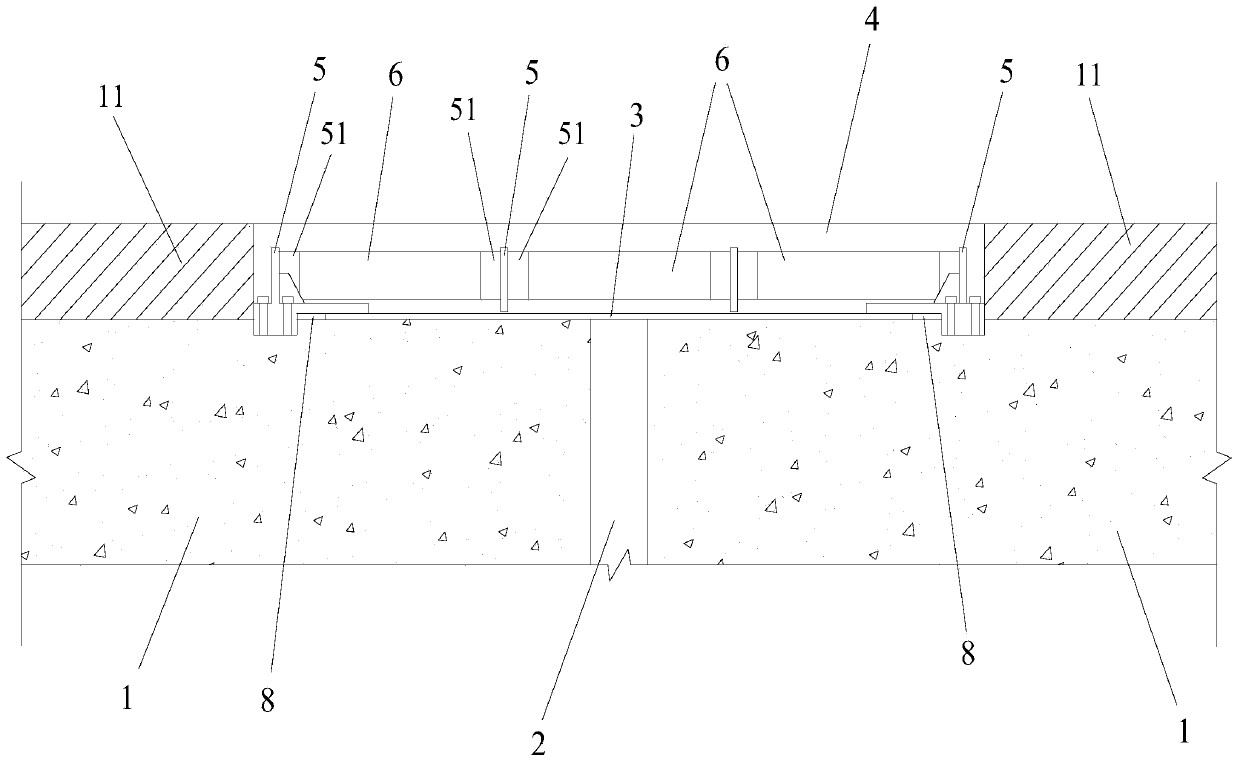

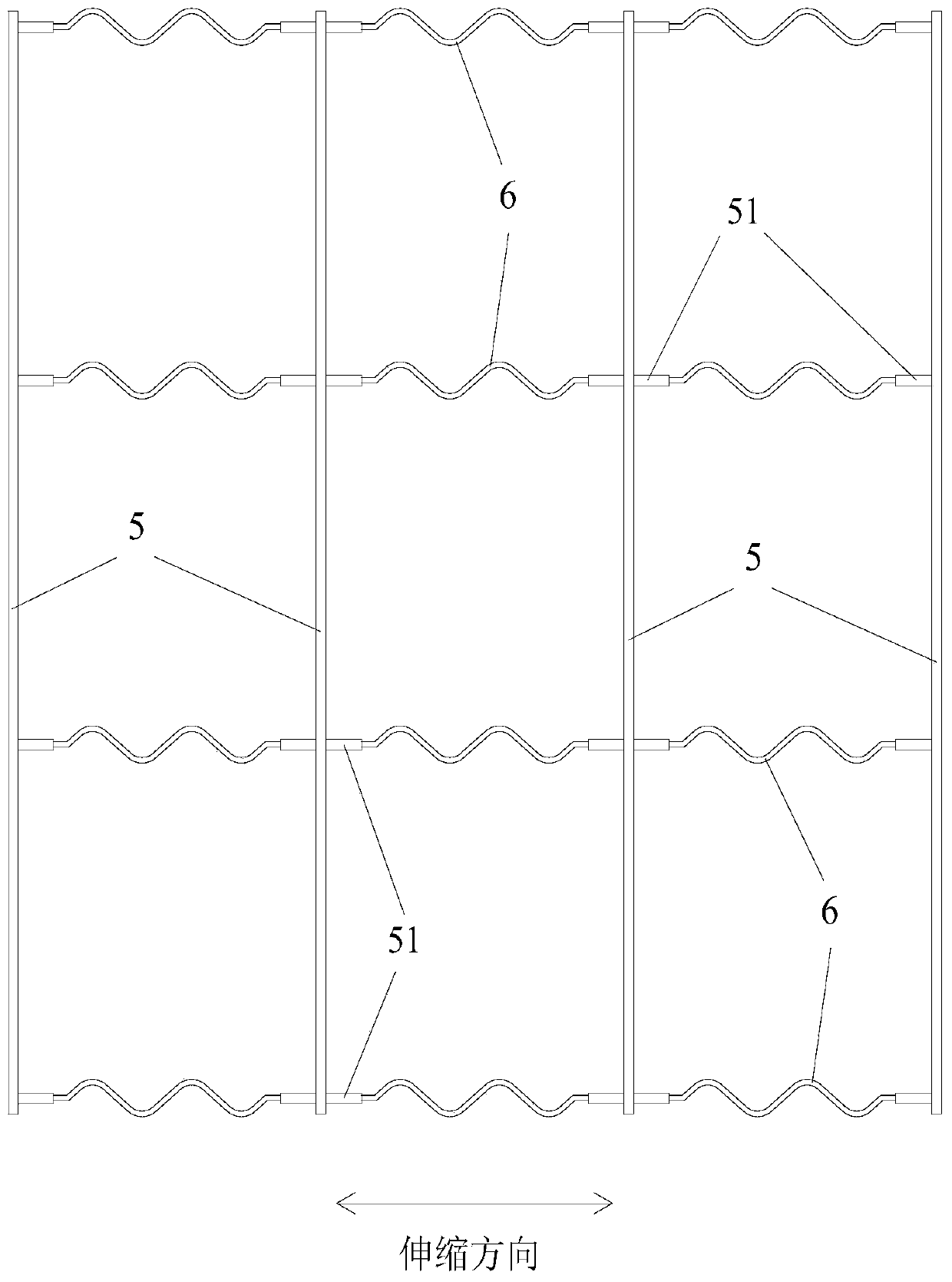

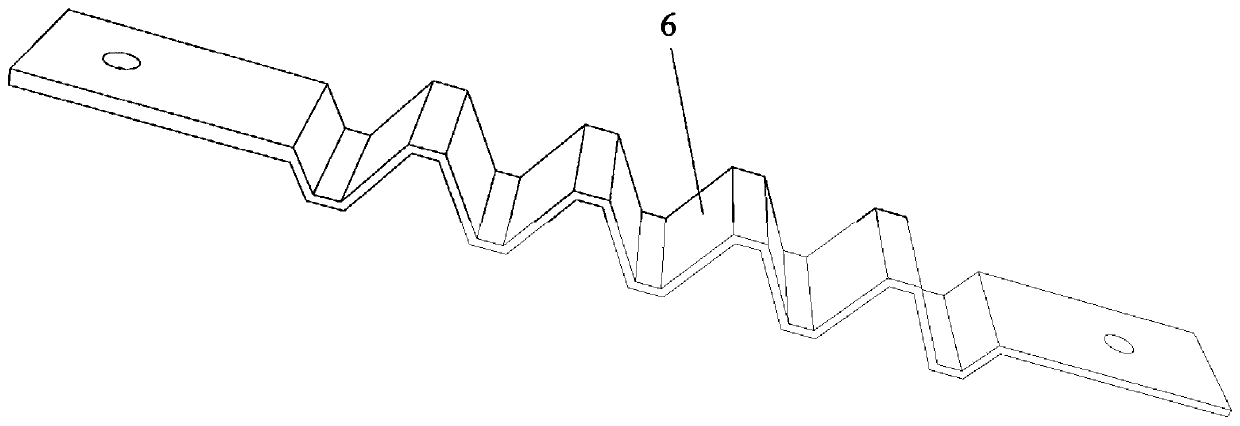

[0038] Such as Figure 1-2 As shown, a seamless expansion joint structure according to the present invention includes expansion joints 2 between two adjacent beam bodies 1, preferably, the width of the expansion joints 2 is 40mm-240mm, and each of the The beam body 1 is provided with a pavement layer 11, and a reserved notch is provided between two adjacent pavement layers 11, and also includes a cover plate 3 arranged on the expansion joint 2, and the cover plate 3 A telescopic member is arranged above, and the telescopic direction of the telescopic member is along the longitudinal direction of the bridge. The elastic-plastic body 4 is filled in the reserved slot, and the top surface of the elastic-plastic body 4 is flush with the top surface of the pavement layer 11. Flat, the elastic-plastic body 4 is a TST structural member, and the TST structural member is a member formed by a mixture of binder and aggregate. Preferably, the size of the telescopic member is adapted to the...

Embodiment 2

[0047] Such as Figure 4 As shown, a seamless expansion joint structure according to the present invention, its structure is roughly the same as that of Embodiment 1, the difference is that all the corrugated plates 6 can be replaced by steel corrugated pipes 7, each The cross-sectional shape of bellows 7 can be circular, elliptical and such as this Figure 4 The approximate elliptical cross-sectional shape, the setting direction of the bellows 7 can be as Figure 4 As shown, that is, the pipe wall of each bellows 7 is connected to the partition 5 or connected to the wall of the adjacent bellows 7 through a connecting piece, and the hollow pipe body is stretched or compressed to deform by pulling and pressing; Certainly, the axial direction of the bellows 7 can also be set along the longitudinal bridge direction, that is, the two ends of each section of the bellows 7 are connected to the two adjacent partitions 5 respectively, and each partition 5 is still provided with The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com