Multifunctional viscosity reducer and preparation method thereof

A viscosity reducer, multifunctional technology, applied in the field of multifunctional viscosity reducer and preparation, can solve the problems of low viscosity reduction rate, fixed viscosity reduction rate, low conversion rate of light components, etc., to reduce viscosity and enhance dispersion Sexuality and activity, the effect of increasing environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

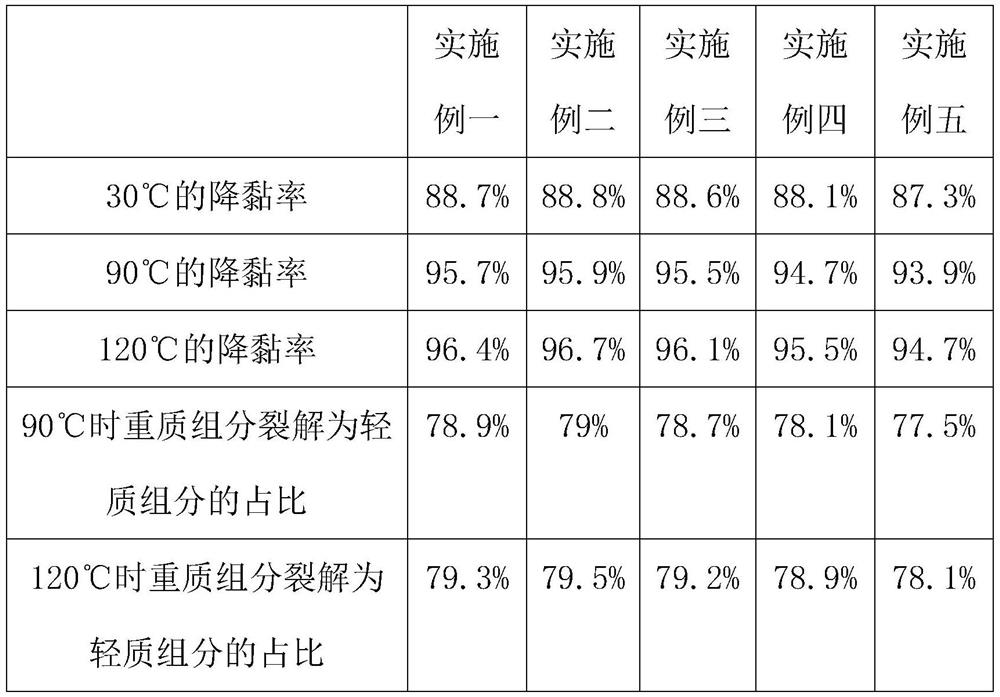

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with specific embodiments.

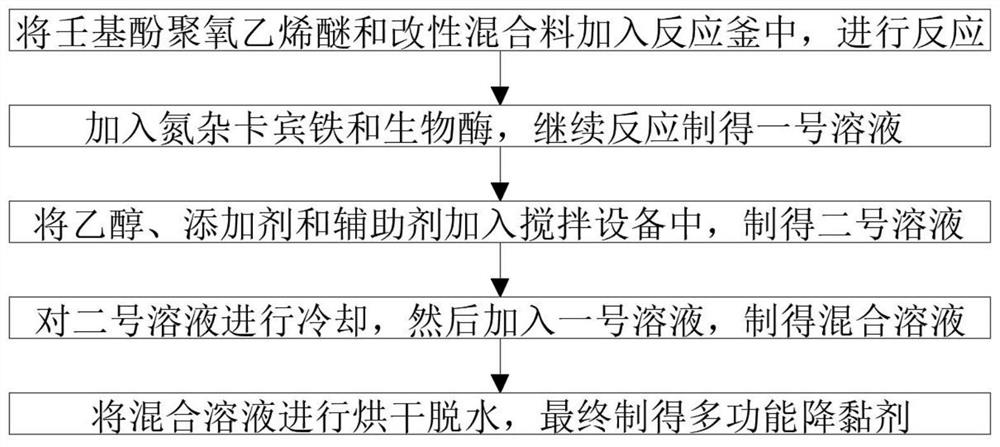

[0024] refer to figure 1 , embodiment one

[0025] In this embodiment, a multifunctional viscosity reducer is proposed, which includes the following components in parts by mass: 20 parts of water, 18 parts of biological enzymes, 10 parts of nonylphenol polyoxyethylene ether, 9 parts of azacarbene iron, 8 parts of ethanol, 6 parts of modified mixture, 5 parts of additives and 5 parts of auxiliary agent, the modified mixture contains modified soda ash and saline-alkali floating soil, and the additive contains compound straw Powder, soda and coal, auxiliary agents include sulfur, clay, biological protein zinc and high mineralization hard water, modification method of soda ash: mix soda ash, ammonium nitrate and biological enzyme according to the ratio of 7:1:2, and then add Reactor, extract the air inside the reactor, control the temperature inside the reactor at 125°C to 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com