Rock breaking device adopting aid of TBM high-voltage pulse water jet

A high-voltage pulse and rock-breaking device technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of low jet pressure, large volume, and no clear use of water jets, etc., and achieve the effect of safely breaking rocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

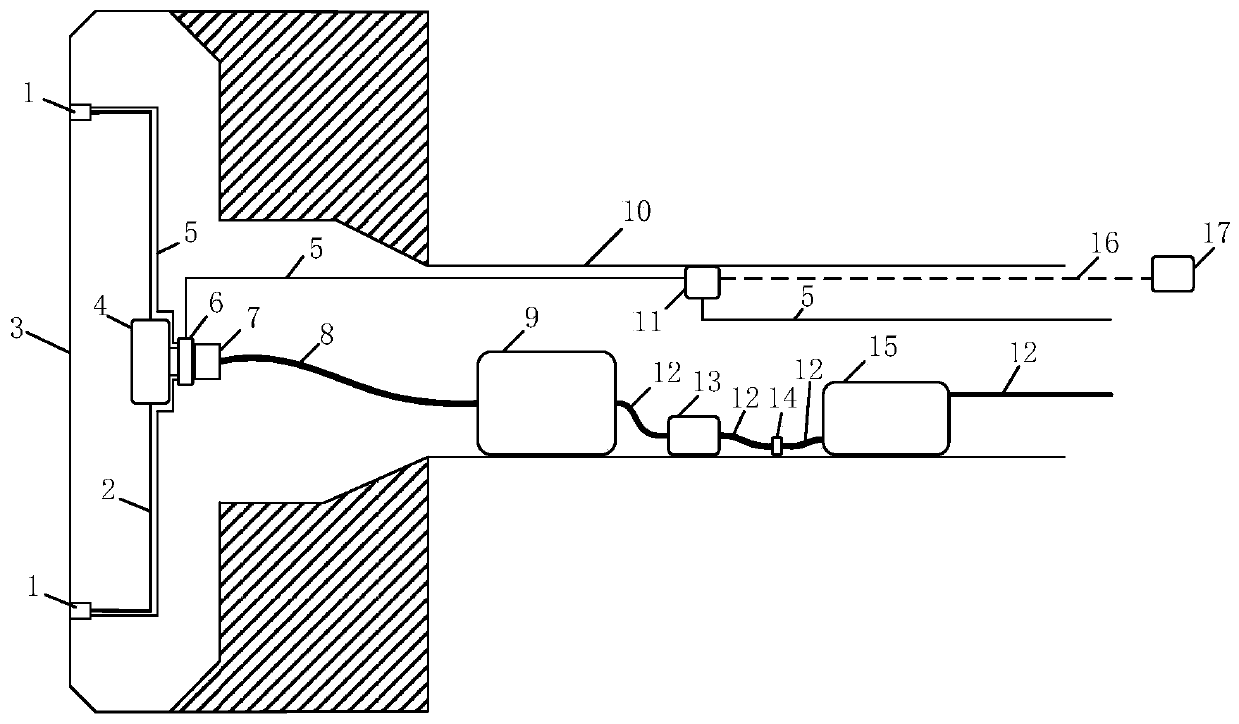

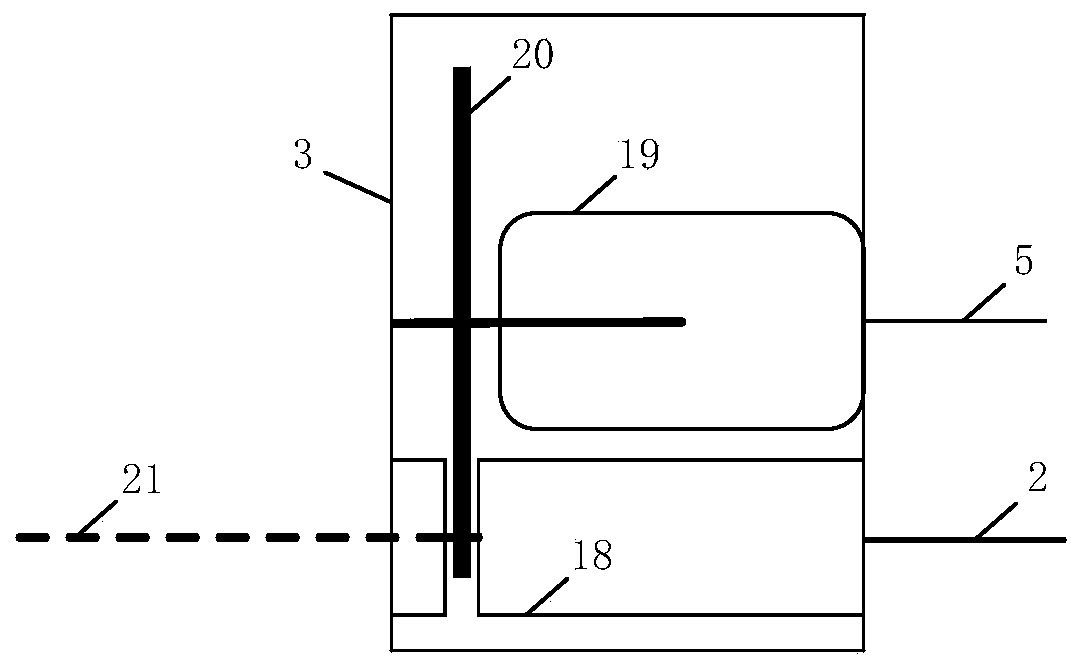

[0022] Please refer to figure 1 with figure 2 , the embodiment of the present invention provides a TBM high pressure pulsed water jet assisted rock breaking device, the device includes:

[0023] Pulse water jet generating device 1, high-pressure water delivery pipeline for cutter head 2, cutter head 3, shunt 4, electric wire 5, conductive slip ring 6, gyrator 7, high-pressure water supply pipeline 8, hydraulic booster 9, main beam 10, Controller 11, low pressure water delivery pipeline 12, water supply pump 13, filter 14, water tank 15, signal line 16 and computer 17;

[0024] The inlet of the water tank 15 is connected with the TBM water supply pipeline, so as to provide water source to the water tank 15 through the TBM water supply pipeline; the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com