Range hood module with electromagnetic heating de-oiling

A heating module and range hood technology, which is applied in the directions of removing oil fume, heating method, induction heating, etc., can solve the problems of slow oil removal, inability to cleanly remove oil stains from the hood, and reducing the satisfaction of oil removal from the range hood, etc. safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

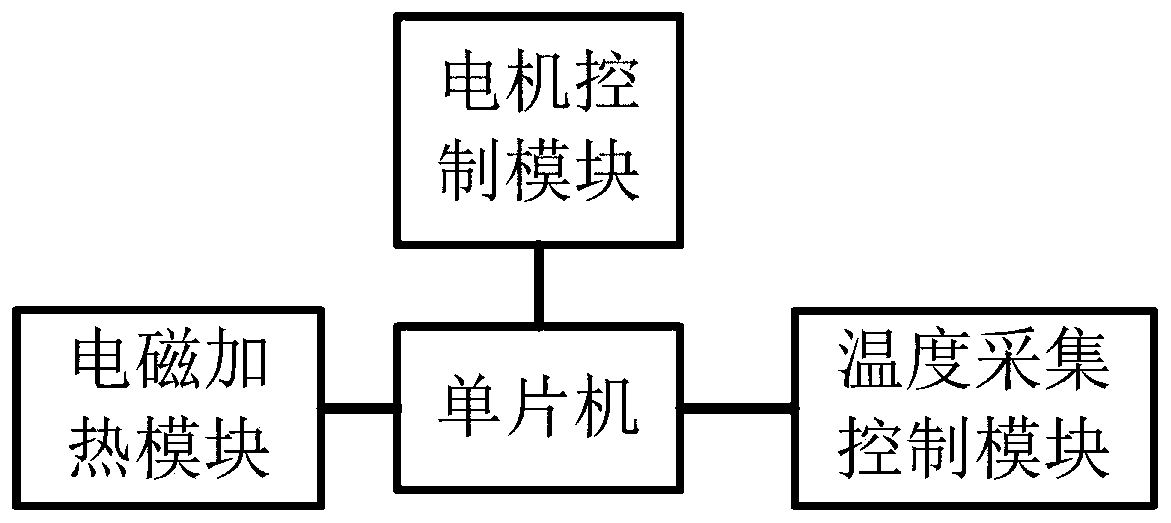

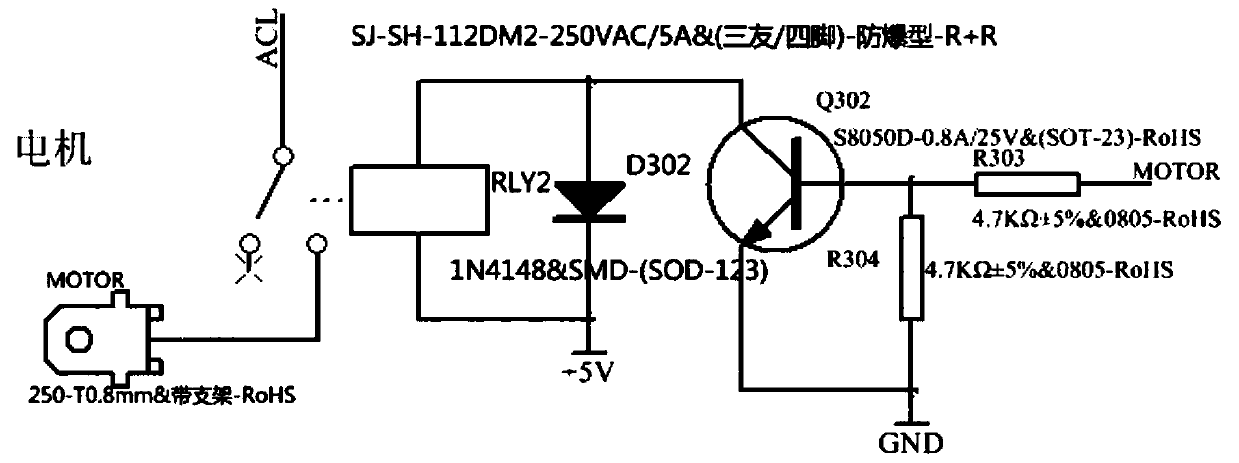

[0020] see Figure 1-Figure 4 , a range hood module with electromagnetic heating and oil removal, including a single-chip microcomputer, and also includes:

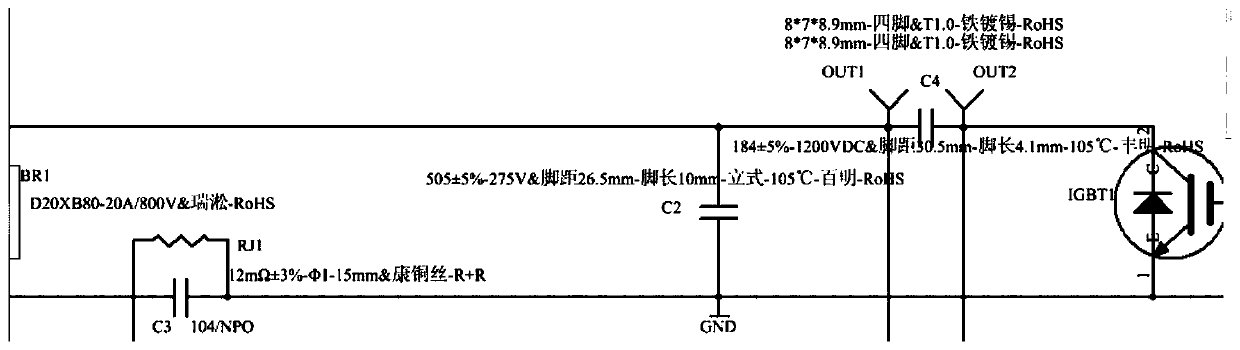

[0021] Electromagnetic heating module, the electromagnetic heating module uses a single-chip microcomputer to control IGBT (Insulated Gate Bipolar Transistor, insulated gate bipolar transistor) to periodically charge and discharge the DC voltage rectified by BR1 on the mains coil and the resonant capacitor. Generate a magnetic field to cut through the fan blade surface of the range hood fan, generate an induced current inside the metal with certain magnetic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com