Fruit size nondestructive detection method based on orthogonal binocular machine vision

A technology of machine vision and non-destructive testing, applied in instruments, measuring devices, image data processing, etc., can solve the problems of large manual grading errors, fruit damage, and low efficiency, and achieve the effects of noise removal, fast extraction, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

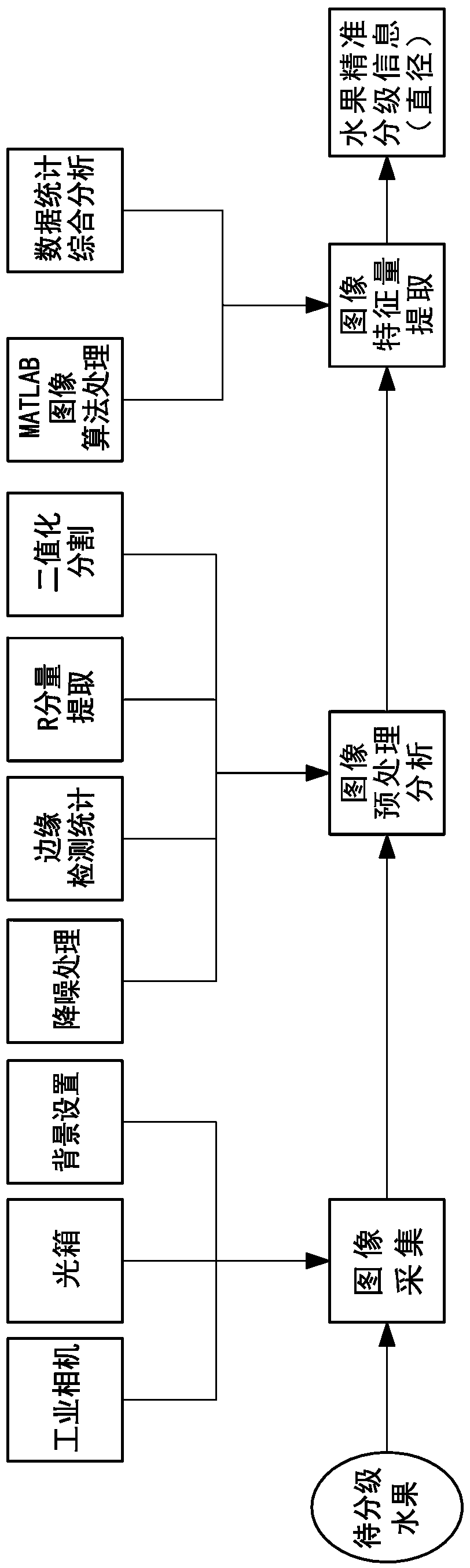

[0050] see Figure 1 to Figure 8 The non-destructive detection method of fruit size based on orthogonal binocular machine vision, the specific steps are as follows:

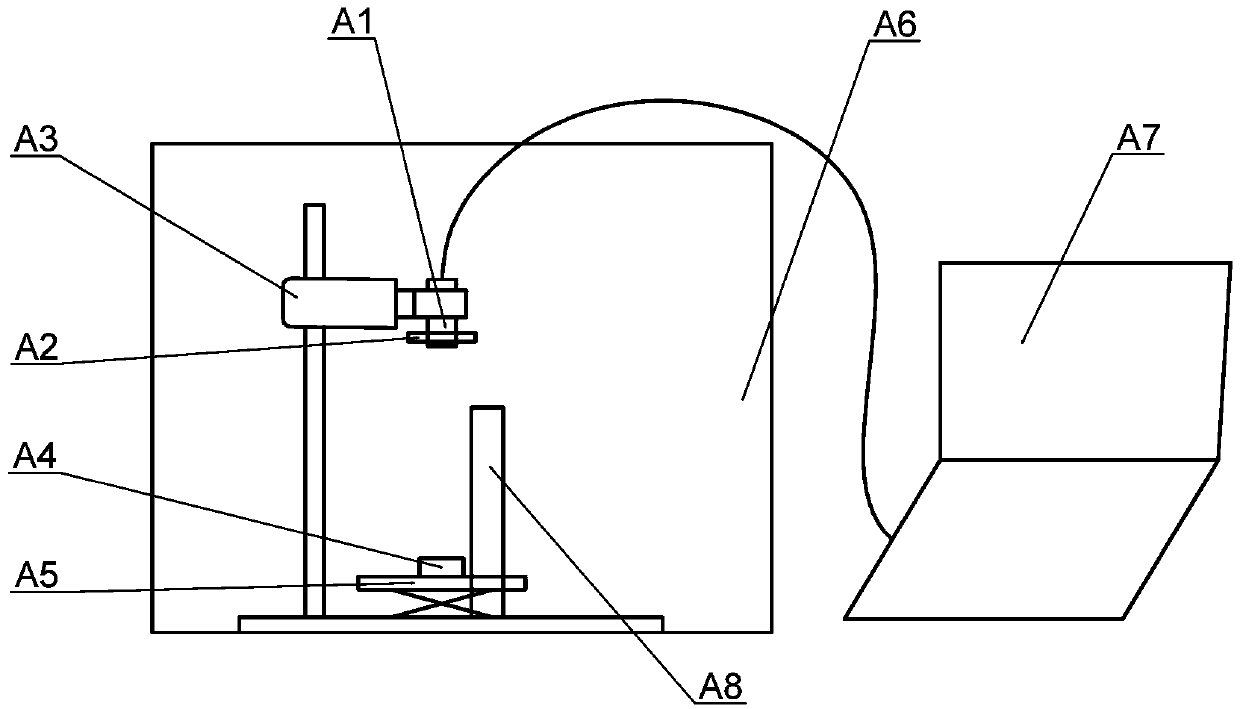

[0051] Step S100): building a monocular machine vision system

[0052] Monocular machine vision system includes industrial camera A1, annular LED stepless dimming light source A2, camera height adjustment mechanism A3, non-mirror cylinder (2cm in height, 5.95cm in diameter) A4, lifting platform A5, light box A6, computer A7 and scale Ruler A8, in which the industrial camera A1, the ring-shaped LED stepless dimming light source A2, the camera height adjustment mechanism A3, the non-mirror cylinder A4, the lifting platform A5 and the scale A8 are placed in the light box A6 resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com