Method and system for detecting macroscopic mura defects on large-size liquid crystal panel

A liquid crystal panel and detection method technology, applied in the field of image processing, can solve problems such as lack of mature technical solutions, achieve the effect of improving detection ability and efficiency, and enhancing images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

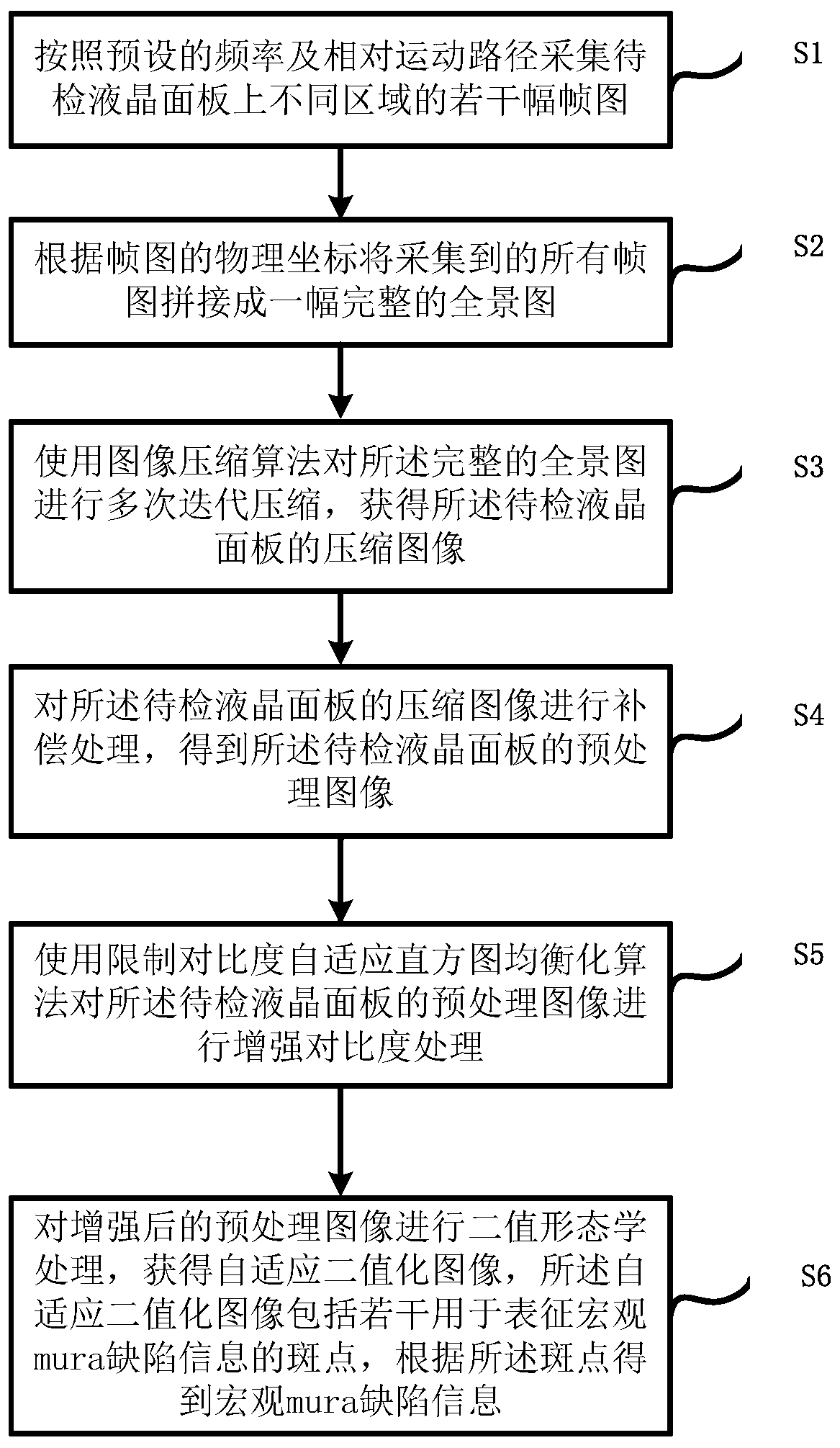

[0050] see figure 1 As shown, an embodiment of the present invention provides a method for detecting macroscopic mura defects on a large-size liquid crystal panel, the method comprising:

[0051] Step S1: Collect several frame images of different regions on the liquid crystal panel to be inspected according to the preset frequency and relative motion path;

[0052] Step S2: Stitching all the collected frame images into a complete panorama according to the physical coordinates of the frame images;

[0053] Step S3: Using an image compression algorithm to iteratively compress the complete panorama multiple times to obtain a compressed image of the liquid crystal panel to be inspected;

[0054] Step S4: performing compensation processing on the compressed image of the liquid crystal panel to be inspected to obtain a preprocessed image of the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com