Airborne closed cold guide machine box

A closed, airborne technology, used in sealed enclosures, cooling/ventilation/heating renovations, electrical components, etc., can solve the problems of high integration, large heat generation, and inability to meet the heat dissipation problems of high-power electronic equipment modules. Improve heat dissipation efficiency and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

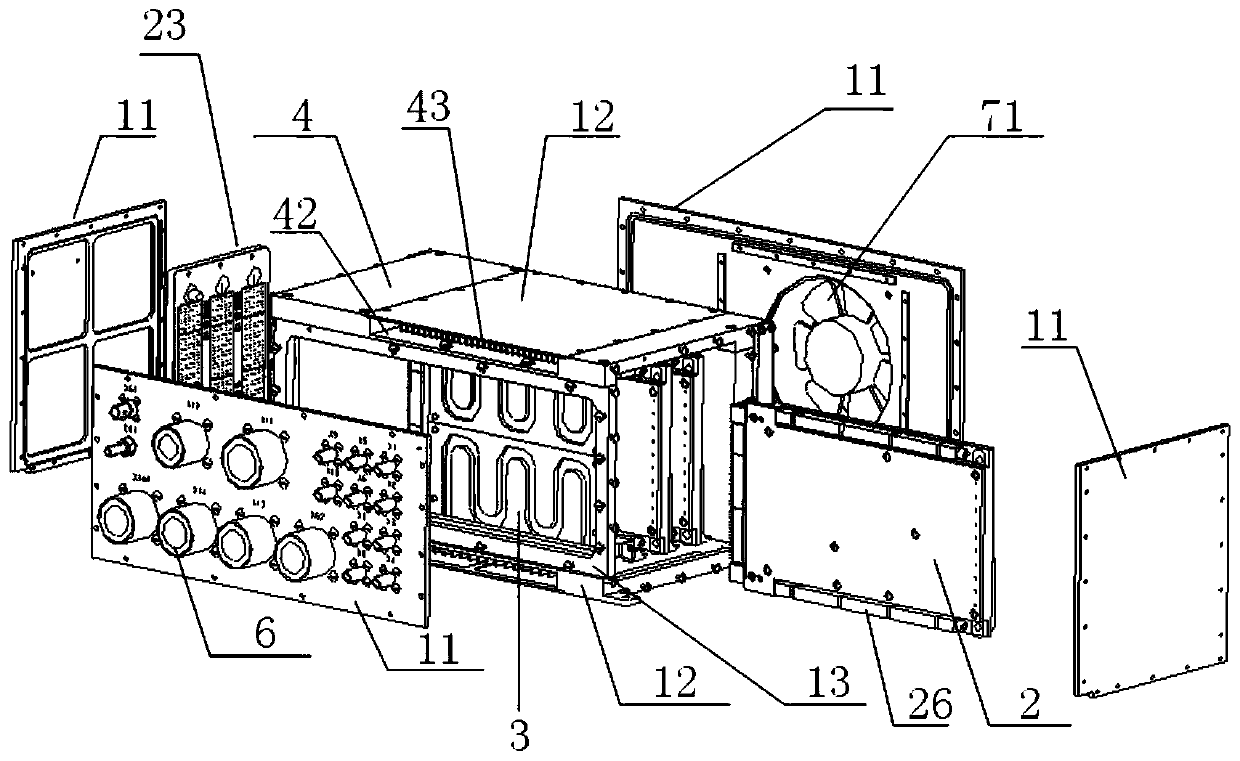

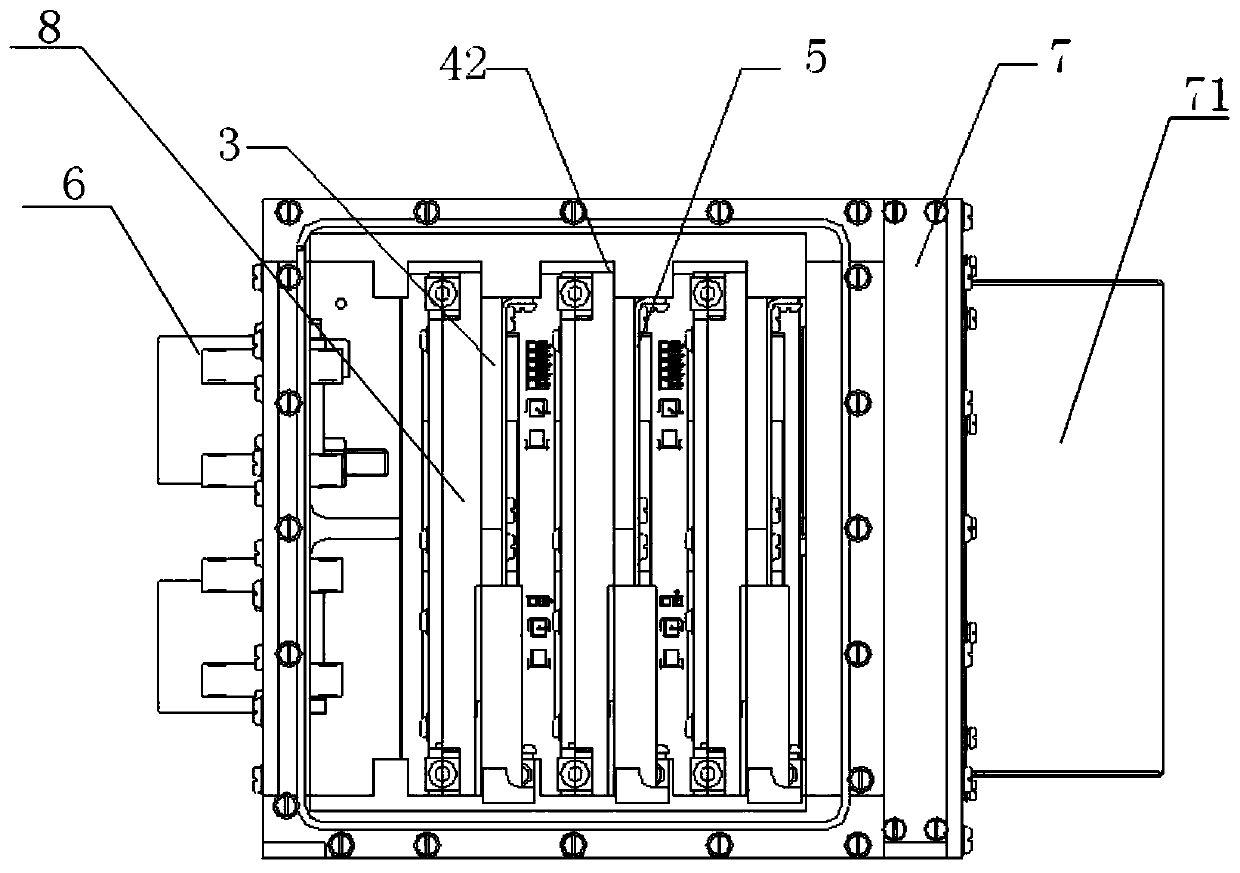

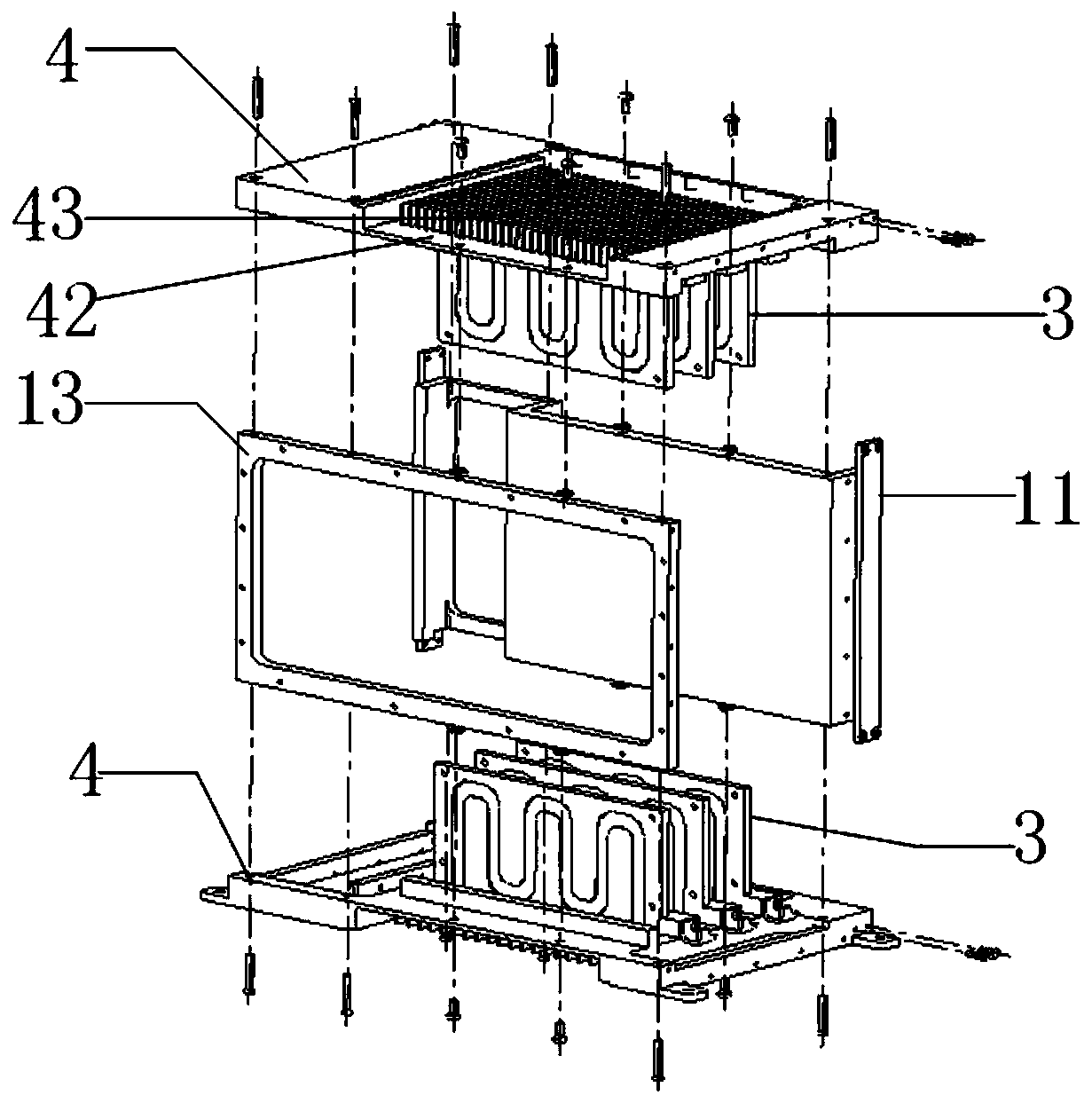

[0038] Such as figure 1 with figure 2 As shown, an airborne airtight cooling conduction chassis of this embodiment includes a box body 1, an electronic plug-in 2, a heat pipe module 3, a cold plate 4, a connecting plate 11, a heat pipe module 3, an air chamber 7, and a fan 71 , nut bar 21, mounting piece 22, motherboard 23, fixing plate 5, IO connecting assembly 6, cover plate 12, one of which connecting plate 11 is between two oppositely arranged cold plates 4, and divides the box body 1 into mutually different Connected electrical cavity 8 and cavity 7; a number of heat pipe modules 3 are integrally connected to the inner wall of the cold plate 4, and the electrical cavity 8 is divided into several insertion channels for installing electronic plug-ins 2, and the two cold plates 4 are oppositely arranged and the heat pipe module 3 on it is correspondingly abutted; the inner concave surface 42 on the outer wall of the cold plate 4 is provided with a number of cooling fins 43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com