Liquid crystal alignment agent composition, method for preparing liquid crystal alignment film using same, and liquid crystal alignment film using same

A technology of liquid crystal aligning agent and composition, which is applied in the direction of liquid crystal materials, chemical instruments and methods, devices for coating liquid on the surface, etc., and can solve problems such as difficulty in ensuring actual yield and large amount of light irradiation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

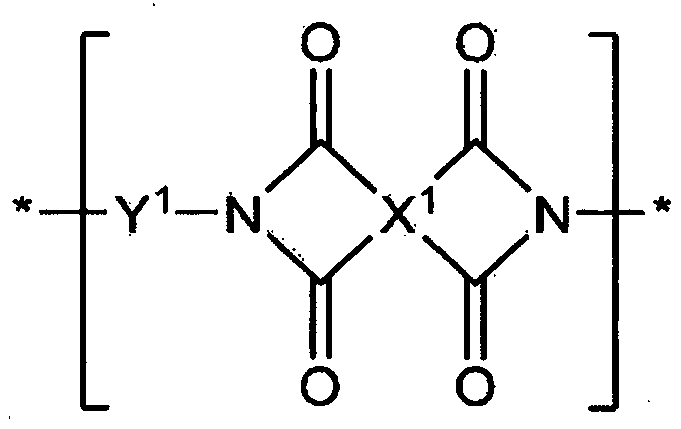

[0151] Production Example 1: Synthesis of Diamine

manufacture example 1-1

[0152] Production Example 1-1) Synthesis of Diamine DA-1

[0153] Diamine DA-1 was synthesized according to the following reaction scheme.

[0154]

[0155] Specifically, 1,3-dimethylcyclobutane-1,2,3,4-tetracarboxylic dianhydride (DMCBDA) and 4-nitroaniline were dissolved in DMF (dimethylformamide) to prepare mixture. Then, the mixture was reacted at about 80° C. for about 12 hours to prepare amic acid. Subsequently, amic acid was dissolved in DMF, and acetic anhydride and sodium acetate were added thereto to prepare a mixture. Then, the amic acid contained in the mixture was imidized at about 90° C. for about 4 hours. The imide thus obtained was dissolved in DMAc (dimethylacetamide), and then Pd / C was added thereto to prepare a mixture. The resulting mixture was reduced under a hydrogen pressure of 6 bar at 45° C. for 20 minutes to prepare diamine DA-1.

manufacture example 1-2

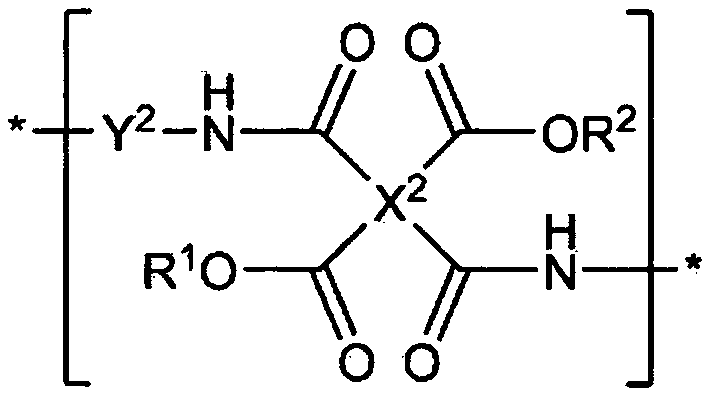

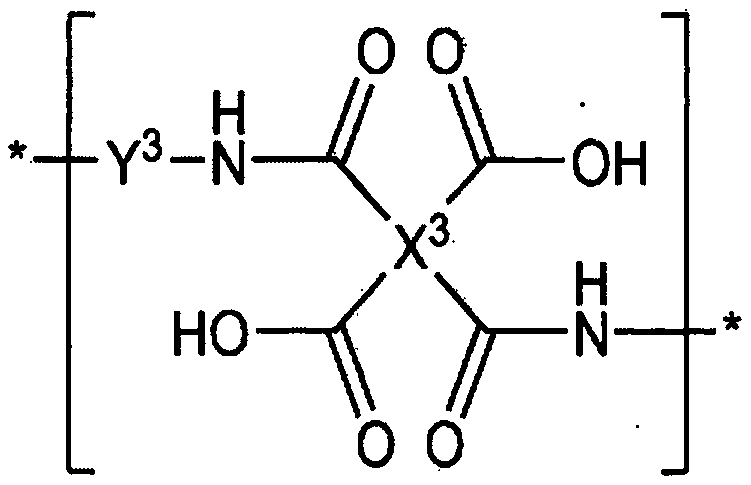

[0156] Production Example 1-2) Synthesis of Diamine DA-2

[0157]

[0158] DA-2 having the above structure was produced in the same manner as in Production Example 1, except that cyclobutane-1,2,3,4-tetracarboxylic dianhydride (CBDA) was used instead of 1,3-dimethyl Cyclobutane-1,2,3,4-tetracarboxylic dianhydride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| rate of viscosity change | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com