Filtering-type spiral-belt stirring and drying machine

A stirring dryer and filtering technology, which is applied in the field of filtering screw belt stirring dryer, can solve the problems of affecting the quality of materials, blocking the filter screen, turning into water droplets, etc., so as to improve product quality and production efficiency, and improve material drying efficiency. , Improve the effect of material quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

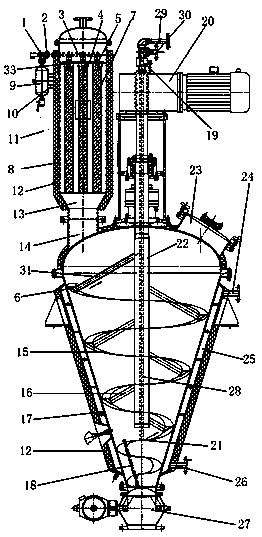

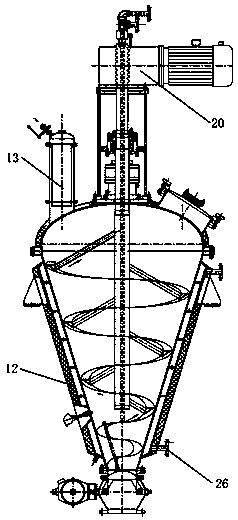

[0014] Such as figure 1 As shown, the filter-type ribbon stirring dryer includes a housing 17, and a discharge ball valve 27 is arranged at the bottom of the housing 17, and the discharge ball valve 27 is a pneumatic eccentric hemispherical valve. The shell 17 is provided with a spiral heating cavity 25 . The heating chamber 25 is covered with the insulation layer 12, and a steam inlet pipe 24 and a steam outlet pipe 26 are provided. The insulation layer 12 is an aluminum silicate insulation layer. The housing 17 is provided with a helical blade 15, and the helical blade 15 is composed of a hollow part at the top and a solid part at the bottom, and the hollow part and the solid part are integrally formed. The top end of the hollow part is provided with an output port 6 and the bottom end is provided with an input port 21 . The spiral blade 15 is fixed on the stirring shaft 22 through the connecting rod 16 . The output port 6 of the hollow part of the helical blade 15 comm...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap