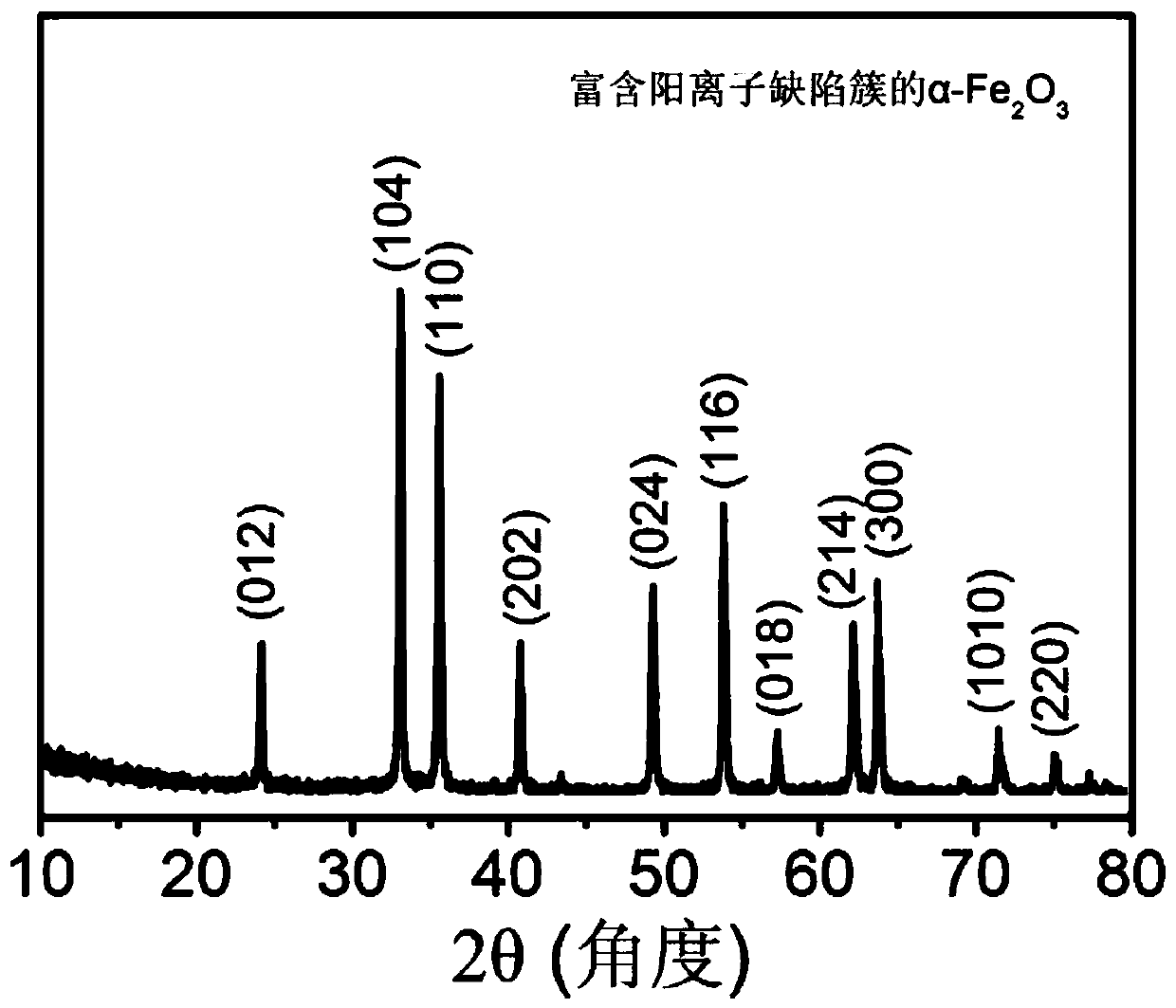

Alpha-Fe2O3 photocatalyst rich in cationic defect cluster and preparation method and application thereof

A photocatalyst, cation technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Photocatalytic degradation activity, the effect of superior organic degradation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Α-Fe rich in cationic defect clusters 2 O 3 The preparation of the photocatalyst includes the following steps:

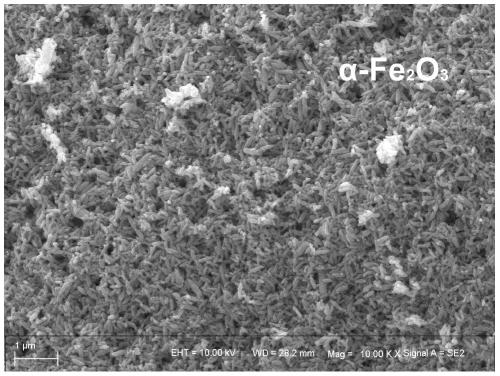

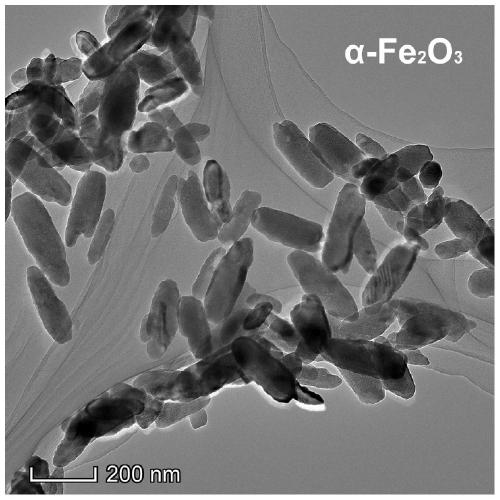

[0040] (1) α-Fe rich in cationic defect clusters 2 O 3 Nanoparticle preparation

[0041] 1.6g of Fe 2 (SO 4 ) 3 ·7H 2 O was placed in 20ml of deionized water and stirred for 20min; 0.96g of NaOH was placed in 20ml of deionized water and stirred for 20min; the above two solutions were mixed, stirred for 10min to mix them thoroughly, and then 1.4g of NaOH was added to the mixed solution Sodium dodecylbenzene sulfonate and 0.16g 2,2'-bipyridine, continue to stir for 20min; transfer the fully mixed solution to a high-temperature reactor, place the reactor in a blast oven and heat it at 180℃ 12h, take out the reaction kettle and let it cool down naturally.

[0042] Use deionized water and absolute ethanol to wash the product three times by centrifugation at 6000 rpm, and dry the washed product at 60°C;

[0043] (2) α-Fe rich in cationic defect clusters 2 O 3 Preparation ...

Embodiment 2

[0047] Α-Fe rich in cationic defect clusters 2 O 3 The preparation of the photocatalyst includes the following steps:

[0048] (1) α-Fe rich in cationic defect clusters 2 O 3 Nanoparticle preparation

[0049] 0.8g of Fe 2 (SO 4 ) 3 ·7H 2 O was placed in 10ml deionized water and stirred for 15min; 0.48g of NaOH was placed in 10ml of deionized water and stirred for 15min; the above two solutions were mixed, stirred for 10min to mix them thoroughly, and then 0.7g of NaOH was added to the mixed solution Sodium dodecylbenzene sulfonate and 0.08g 2,2'-bipyridine, continue to stir for 10 minutes; transfer the fully mixed solution to a high temperature reactor, place the reactor in a blast oven, and heat at 150°C 15h, take out the reaction kettle and let it cool down naturally.

[0050] The product was centrifuged and washed 5 times with deionized water and absolute ethanol at 6000 rpm, and the washed product was dried at 60°C;

[0051] (2) α-Fe rich in cationic defect clusters 2 O 3 Prepara...

Embodiment 3

[0054] Α-Fe rich in cationic defect clusters 2 O 3 The preparation of the photocatalyst includes the following steps:

[0055] (1) α-Fe rich in cationic defect clusters 2 O 3 Nanoparticle preparation

[0056] 1.2g of Fe 2 (SO 4 ) 3 ·7H 2 O was placed in 15ml deionized water and stirred for 15min; 0.64g of NaOH was placed in 10ml of deionized water and stirred for 15min; the above two solutions were mixed, stirred for 10min to mix them thoroughly, and then 0.9g of NaOH was added to the mixed solution Sodium dodecylbenzene sulfonate and 0.12g 2,2'-bipyridine, continue to stir for 20min; transfer the fully mixed solution to a high temperature reactor, place the reactor in a blast oven, and heat at 150℃ 15h, take out the reaction kettle and let it cool down naturally.

[0057] Use deionized water and absolute ethanol to wash the product three times by centrifugation at 6000 rpm, and dry the washed product at 60°C;

[0058] (2) α-Fe rich in cationic defect clusters 2 O 3 Preparation of Na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com