Novel double-rail spraying production line

A production line, double-track technology, applied in the direction of spraying booths, spraying devices, etc., can solve the problems of rough and uneven thickened surface, easy peeling or bursting of coating, and inability to add extra thick, so as to reduce production pollution and achieve smooth and uniform spraying effect , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in further detail below by example, and these examples are only used for illustrating the present invention, do not limit the scope of the present invention;

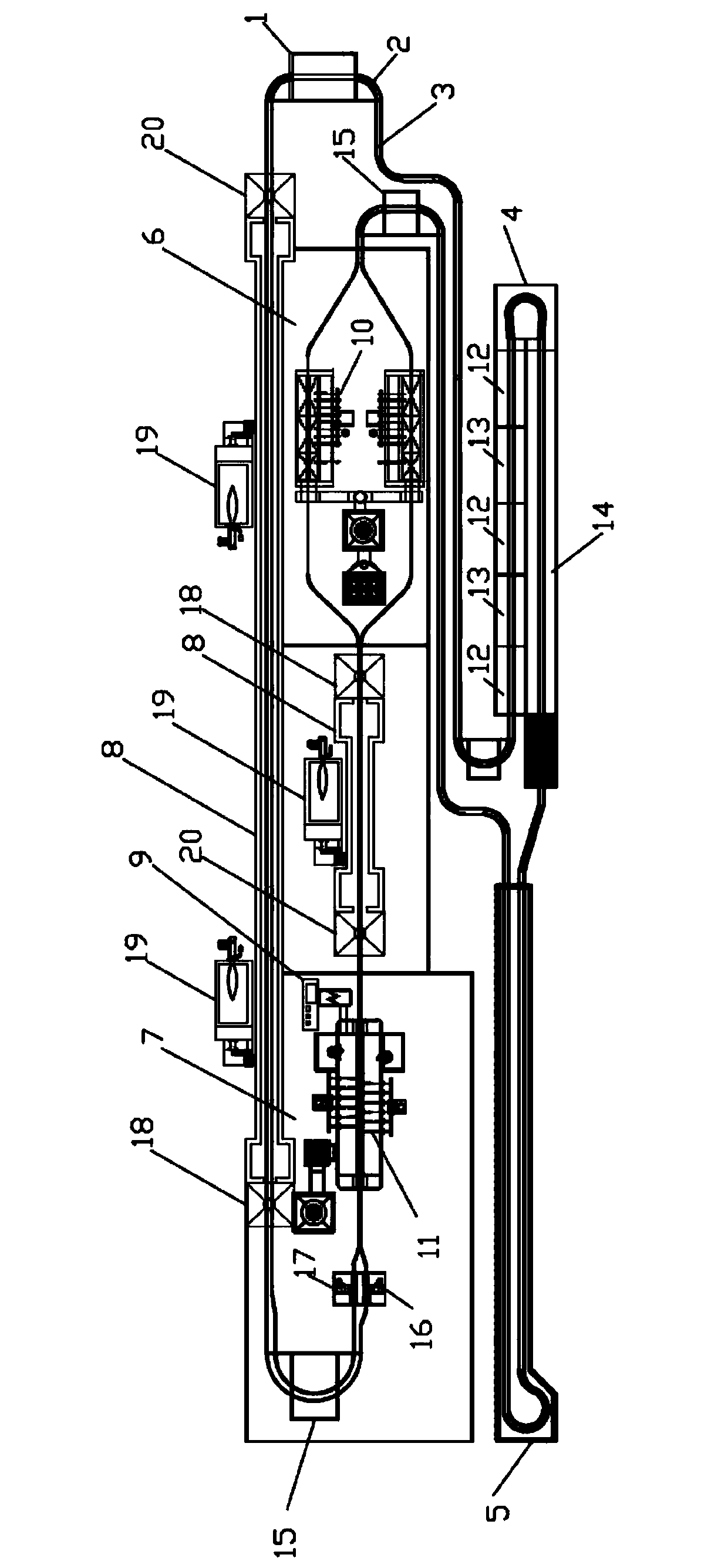

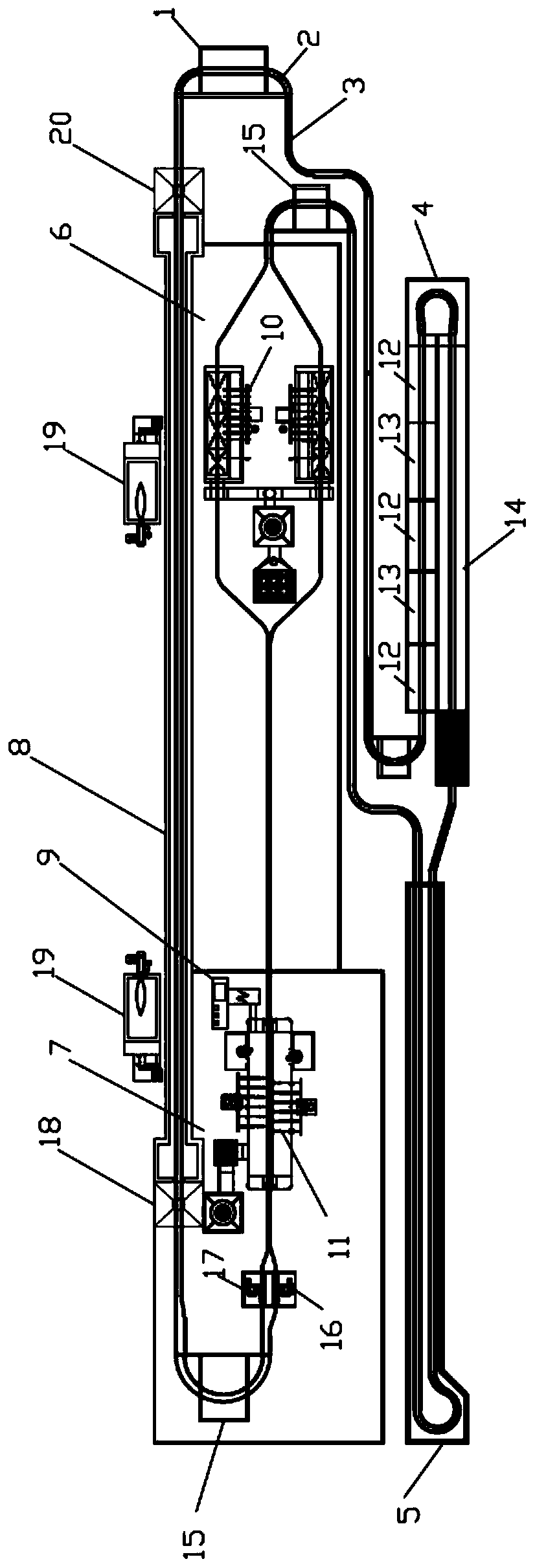

[0017] Such as figure 1 As shown, a new double-track spraying production line includes loading and unloading table 1, first conveying track 2, second conveying track 3, cleaning room 4, drying room 5, first spraying room 6, second spraying room 7 and curing channel 8; It is characterized in that the first conveying track 2 and the second conveying track 3 are connected end-to-end side by side, and are sequentially connected to the loading and unloading platform 1, the cleaning room 4, the drying room 5, the first spraying room 6, the second The second spraying chamber 7 and the curing channel 8 form a production line; in the first spraying chamber 6, two sets of spray heads I10 are arranged between the first conveying track 2 and the inner side of the second conveying track 3, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com