Screwdriver handle preparation method and screwdriver

A screwdriver and handle technology, used in the preparation of screwdriver handles and the field of screwdrivers, can solve the problems of lower connection strength between the blade and the handle, lower production quality of screwdrivers, and reduced distance between chains, etc. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

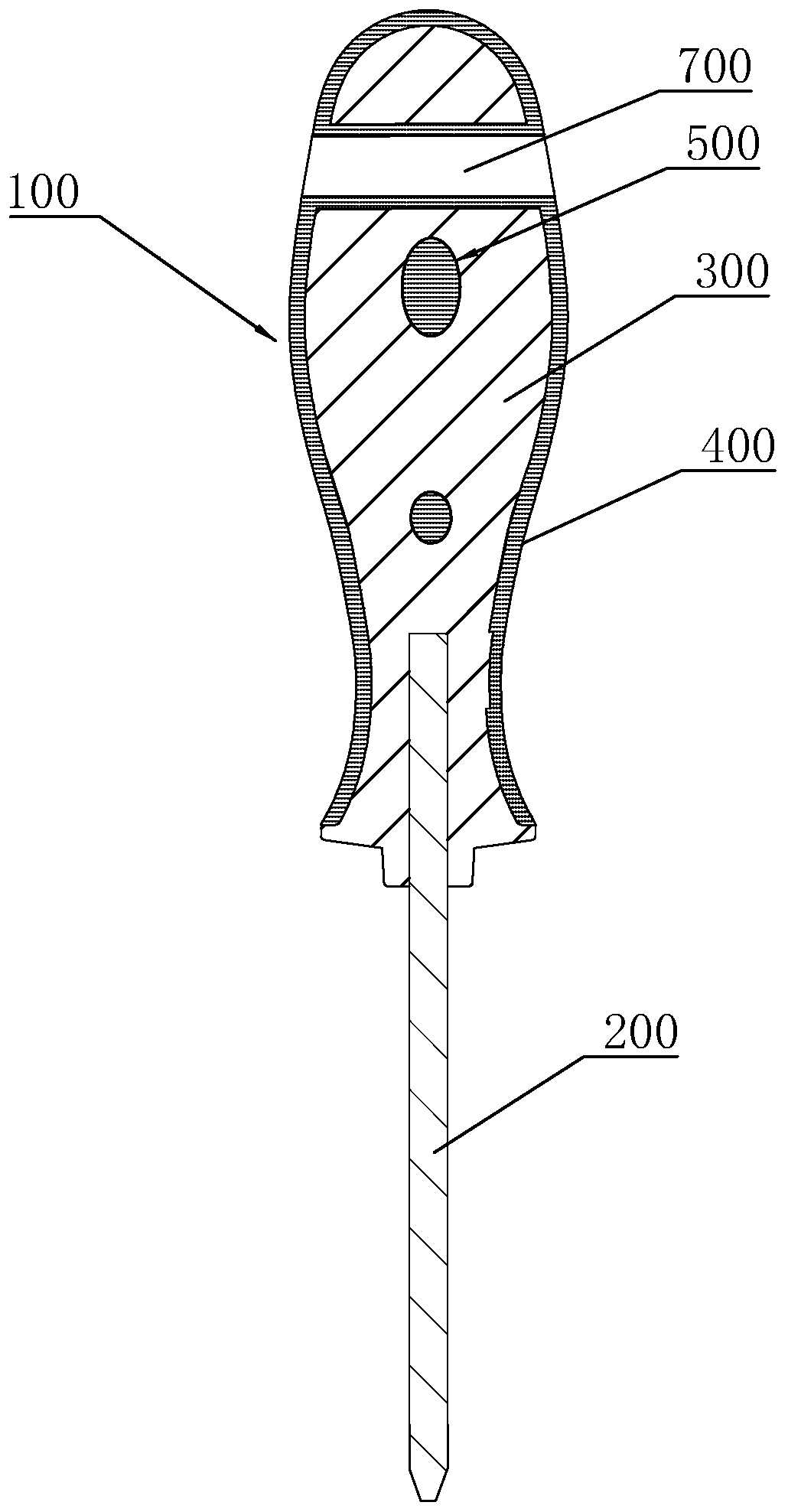

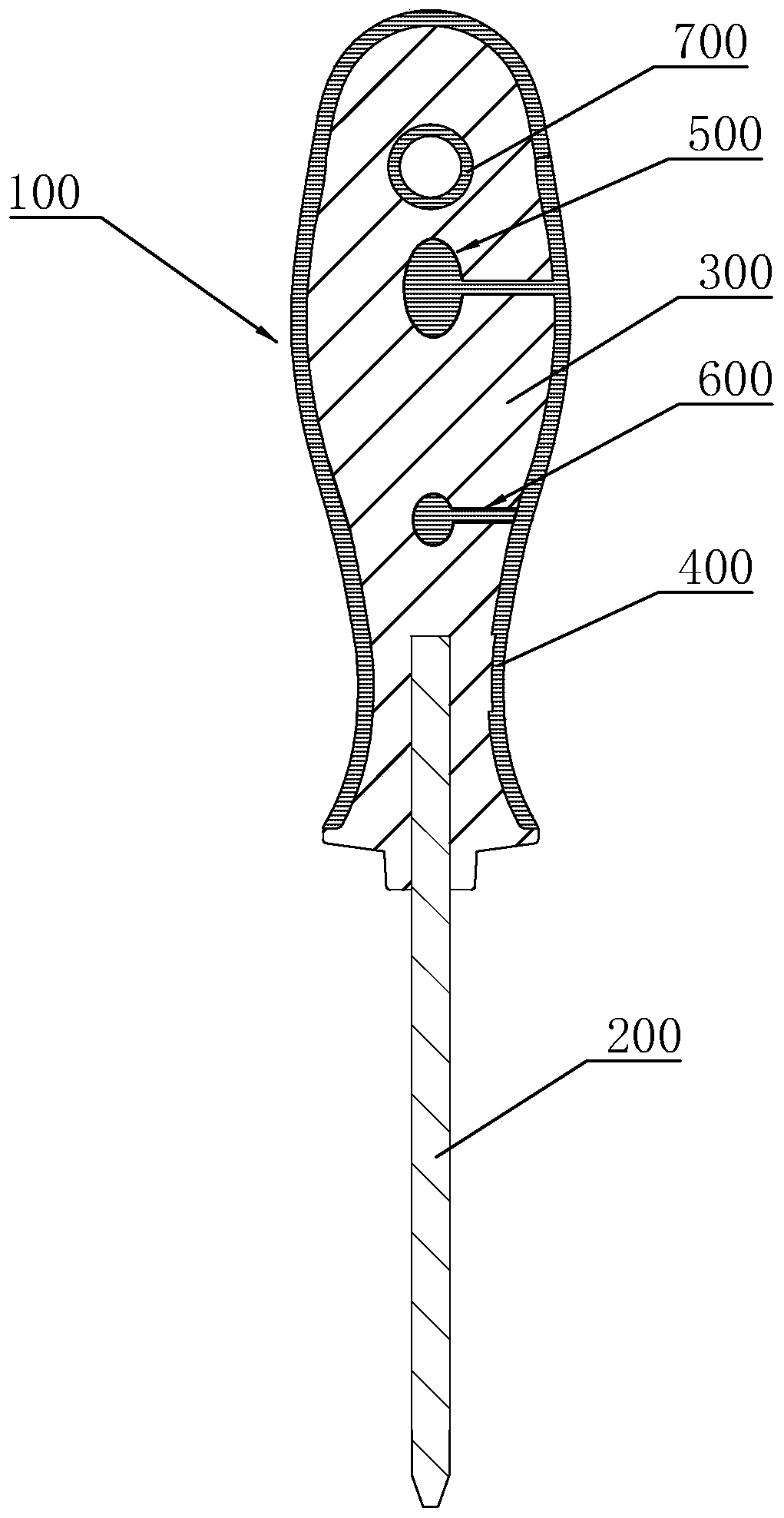

[0038] A kind of preparation method of screwdriver handle, refer to figure 1 and figure 2 , including the following steps:

[0039] Step100: Injecting the inner core 300, and the inner core 300 is provided with a channel 600 connecting the cavity 500 and the outside;

[0040] Step200: Place the inner core 300 in a cooling medium for cooling, and the interface of the cooling medium is located under the channel 600;

[0041] Step300: Injecting the outer layer 400 at least once to fill the channel 600 and the cavity 500 .

[0042] Based on Step 100, the inner core 300 is pressed in an injection molding machine at a temperature of 180°C-220°C for 13-17s, and then cooled naturally for 20-25s. In the above steps, the knife rod 200 and the inner core 300 are injection molded at one time, and the knife rod 200 is connected with the inner core 300 when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com