Preparation method of coal-based vinyl acetate carrier carbon

A technology of coal-based vinyl acetate and vinyl acetate is applied in the field of preparation of coal-based vinyl acetate carrier carbon, which can solve the problems of low acetic acid adsorption capacity, large catalyst consumption, and difficulty in activation of the carbon, such as low abrasion resistance, so as to improve the activation yield. and product performance, catalytic activity and high strength, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Grind Taixi anthracite with an ash content less than 3wt% to D90<75μm, knead Taixi anthracite, water, coal tar and coal tar pitch in a twin-shaft stirring kneader in a weight ratio of 100:6:33:6 to form a coal paste , and then extruded into carbon strips on a hydraulic molding machine; after the carbon strips are dried and solidified, they enter the carbonization furnace for carbonization at 650°C; the obtained carbonized materials are sent to the activation furnace, and high-temperature water vapor is introduced to activate once at 910°C 15min to obtain the primary activation material, then cool the primary activation material to 30°C, and then re-send it into the activation furnace, and feed high-temperature water vapor, and perform secondary activation at 950°C, the secondary activation time is 25min, and get Secondary activating material; Gained secondary activating material concentration is 5wt%, its volume is 2.5 times of hydrochloric acid (that is, the volume rati...

Embodiment 2

[0064] Compared with embodiment 1, only following difference:

[0065] The weight ratio of Taixi anthracite, water, coal tar and coal tar pitch is 100:6:33:10.

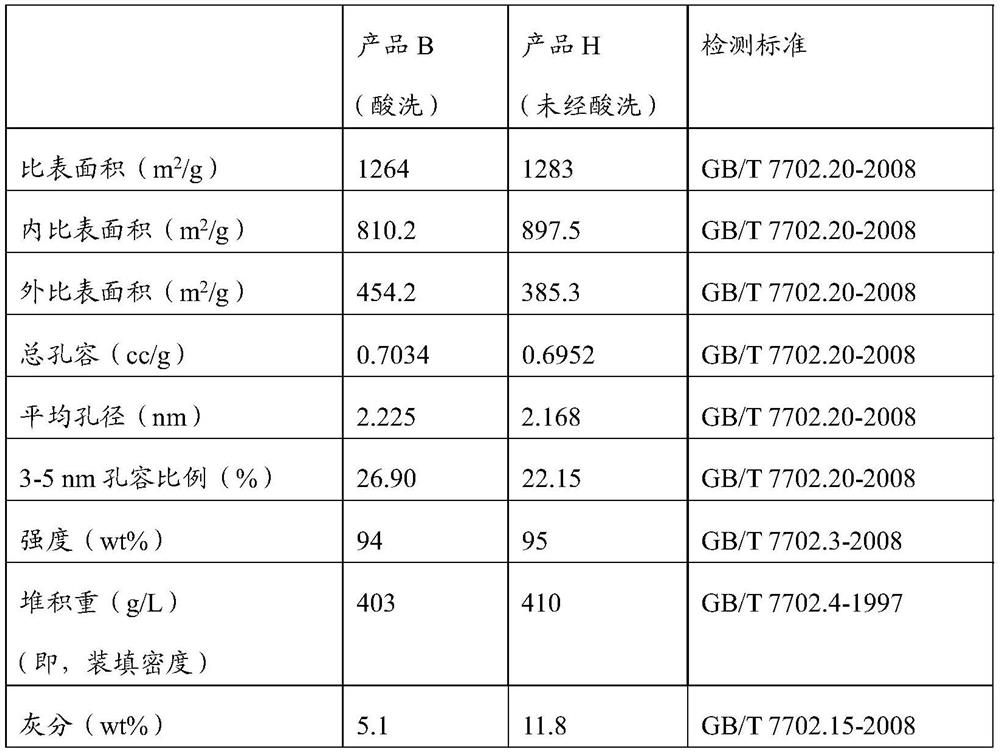

[0066] The coal-based vinyl acetate carrier carbon obtained by it is recorded as product B. The ash content of product B is 5.1wt%, the adsorption capacity of acetic acid is 535mg / g, the adsorption capacity of zinc acetate is 5.29g / 100ml, and the strength is 95wt%.

Embodiment 3

[0068] Compared with embodiment 1, only following difference:

[0069] The primary activation time is 20 minutes, and the secondary activation time is 30 minutes.

[0070] The coal-based vinyl acetate carrier carbon obtained by it is recorded as product C, the ash content of product C is 5.1wt%, the adsorption capacity of acetic acid is 548mg / g, the adsorption capacity of zinc acetate is 5.39g / 100ml, and the strength is 94wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap