Intumescent waterproof sealing material and construction method thereof

A technology of waterproof sealing and construction method, which is used in building insulation materials, cement production, other household appliances, etc. It can solve the problem of excessive use of waterproofing agents, and achieve controllable material density and filling volume, high workability, and waterproofing. Good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

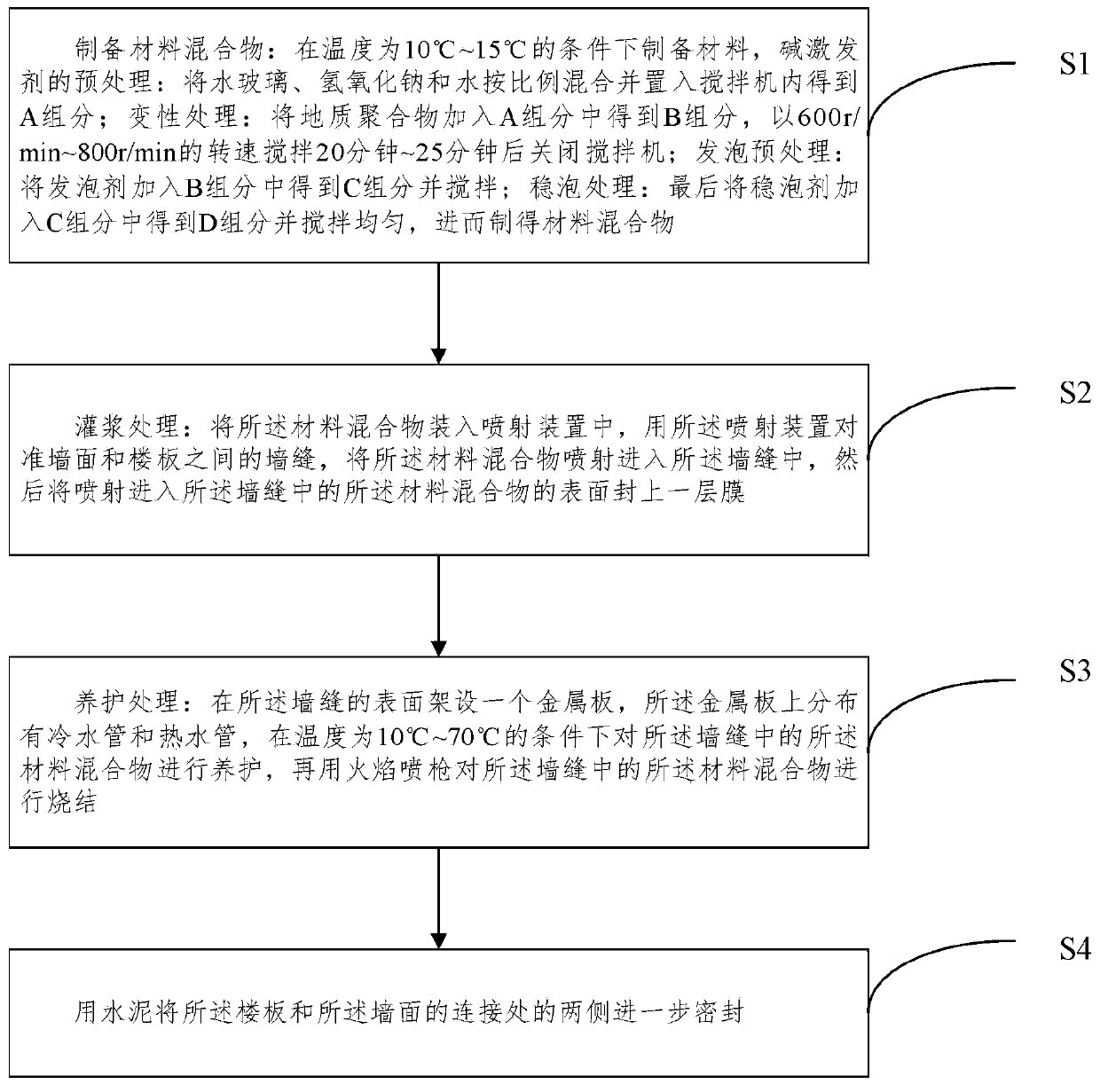

Method used

Image

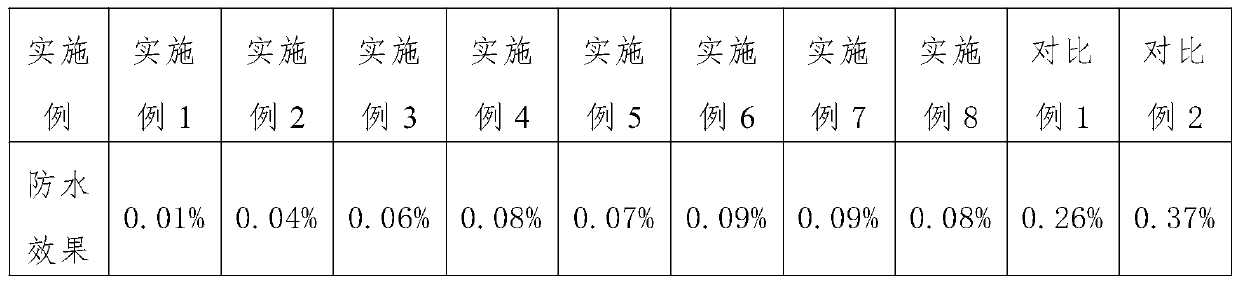

Examples

Embodiment 1

[0040] In parts by mass: 100 parts of geopolymer, 90 parts of water glass, 20 parts of sodium hydroxide, 30 parts of water, 4 parts of hydrogen peroxide, and 2 parts of washing powder.

[0041] Prepare materials at a temperature of 12°C, pretreatment of alkali activator: mix 90 parts of water glass, 20 parts of sodium hydroxide and 30 parts of water in proportion and put them into a mixer to obtain component A; denaturation Treatment: add 100 parts of geopolymer to component A to obtain component B, stir at a speed of 600r / min for 20 minutes and then turn off the mixer; foaming pretreatment: add 4 parts of hydrogen peroxide to component B to obtain group C Divide and stir; foam stabilization treatment: finally add 2 parts of washing powder to component C to obtain component D and stir evenly to obtain a material mixture;

[0042] Next, put the prepared material mixture into the injection device, aim the injection device at the wall seam between the wall and the floor, and spra...

Embodiment 2

[0046] In parts by mass: 80 parts of geopolymer, 50 parts of water glass, 20 parts of sodium hydroxide, 30 parts of water, 4 parts of hydrogen peroxide, and 2 parts of washing powder.

[0047] Prepare materials at a temperature of 12°C, pretreatment of alkali activator: mix 50 parts of water glass, 20 parts of sodium hydroxide and 30 parts of water in proportion and put them into a mixer to obtain component A; denature Treatment: add 100 parts of geopolymer to component A to obtain component B, stir at a speed of 600r / min for 20 minutes and then turn off the mixer; foaming pretreatment: add 4 parts of hydrogen peroxide to component B to obtain group C Divide and stir; foam stabilization treatment: finally add 2 parts of washing powder to component C to obtain component D and stir evenly to obtain a material mixture;

[0048] Next, put the prepared material mixture into the injection device, aim the injection device at the wall seam between the wall and the floor, and spray the...

Embodiment 3

[0052] In parts by mass: 100 parts of geopolymer, 90 parts of water glass, 5 parts of sodium hydroxide, 30 parts of water, 4 parts of hydrogen peroxide, and 2 parts of washing powder.

[0053] Prepare materials at a temperature of 12°C, pretreatment of alkali activator: mix 90 parts of water glass, 5 parts of sodium hydroxide and 30 parts of water in proportion and put them into a mixer to obtain component A; denature Treatment: add 100 parts of geopolymer to component A to obtain component B, stir at a speed of 600r / min for 20 minutes and then turn off the mixer; foaming pretreatment: add 4 parts of hydrogen peroxide to component B to obtain group C Divide and stir; foam stabilization treatment: finally add 2 parts of washing powder to component C to obtain component D and stir evenly to obtain a material mixture;

[0054] Next, put the prepared material mixture into the injection device, aim the injection device at the wall seam between the wall and the floor, and spray the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com