TBM emergency water burst resistant system

A technology of anti-surge and dam filling, which is applied in mining equipment, tunnels, earth-moving drilling, etc., can solve the problems of high flow rate and influence of TBM equipment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

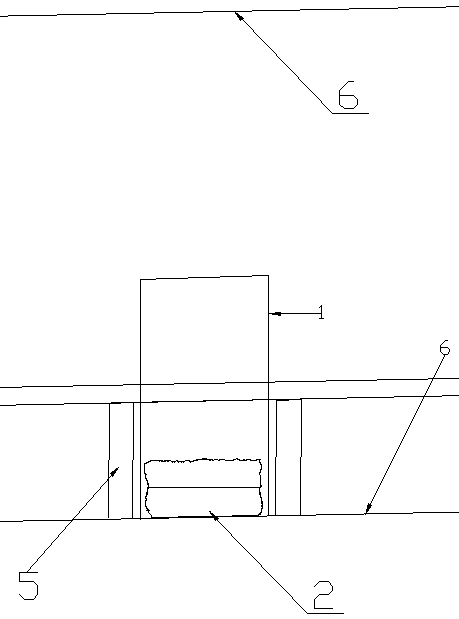

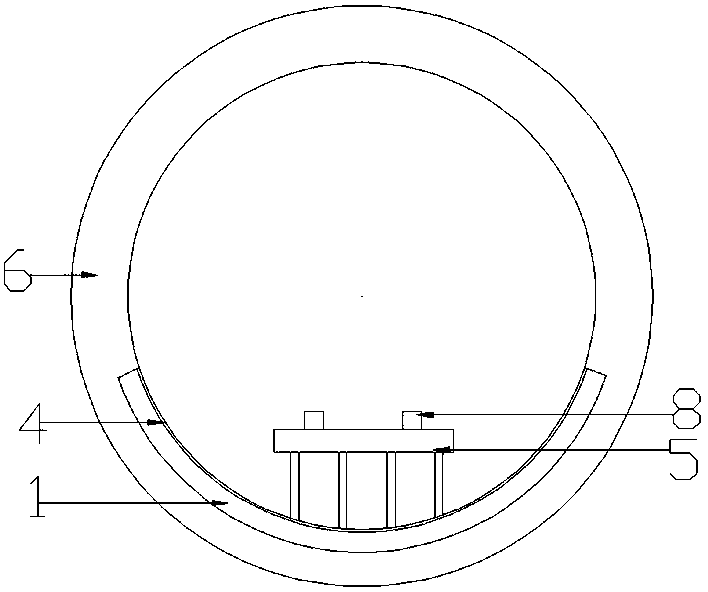

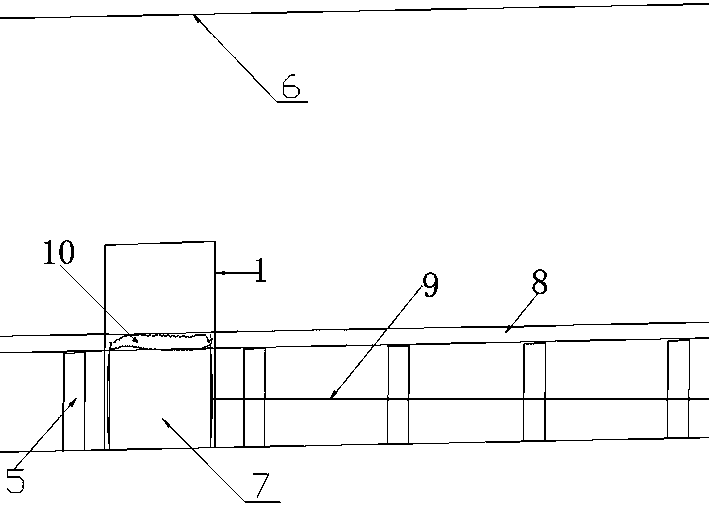

[0019] A TBM emergency anti-surge system, in which a circular groove 1 is arranged on the tunnel wall at the end of the excavated TBM, and a rubber filling dam 2 is placed in the circumferential groove. There is a fixing belt on the outside of the rubber filling dam 2, and the fixing belt 3 passes through the anchor Fixed on the periphery of the circumferential groove, the rubber filling dam 2 is filled with water through the existing TBM water supply pipe connected to the branch pipe, and the valve is installed on the branch pipe. The rubber filling dam 2 has at least two upper and lower layers, and each layer has a separate water filling port and water discharge port. The two sides of each layer are curved to match the circumferential groove. If it is filled with water, it will gradually widen from bottom to top, similar to the shape of a protractor.

[0020] The water-filled height of the rubber-filled dam 2 is 1 / 4 to 1 / 2 of the tunnel height, which basically meets the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com