Silicone oil fan clutch capable of switching high and low speeds quickly

A clutch and silicone oil technology, applied in machine/engine, coolant flow control, engine components, etc., can solve problems such as increased engine power consumption, shortened engine service life, increased engine combustion, etc., to reduce oil return time, shorten Separation time to low speed, effect of fast separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

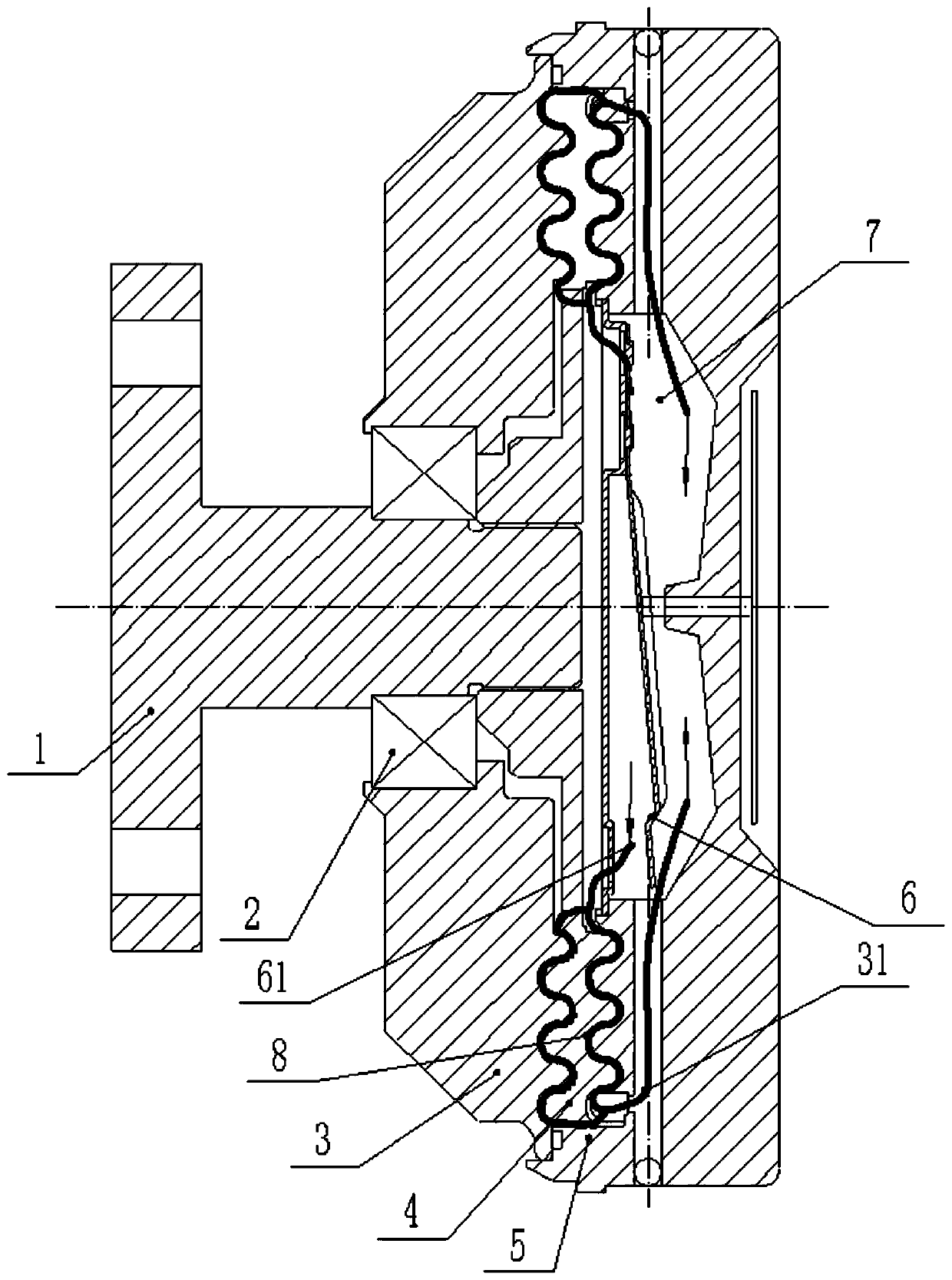

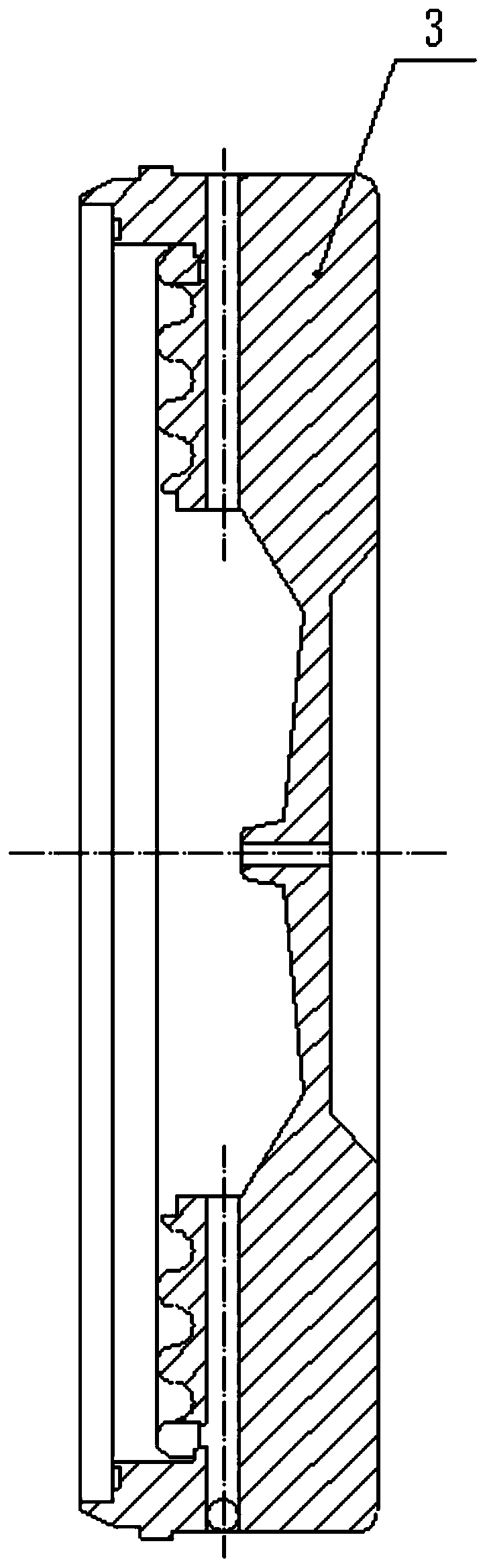

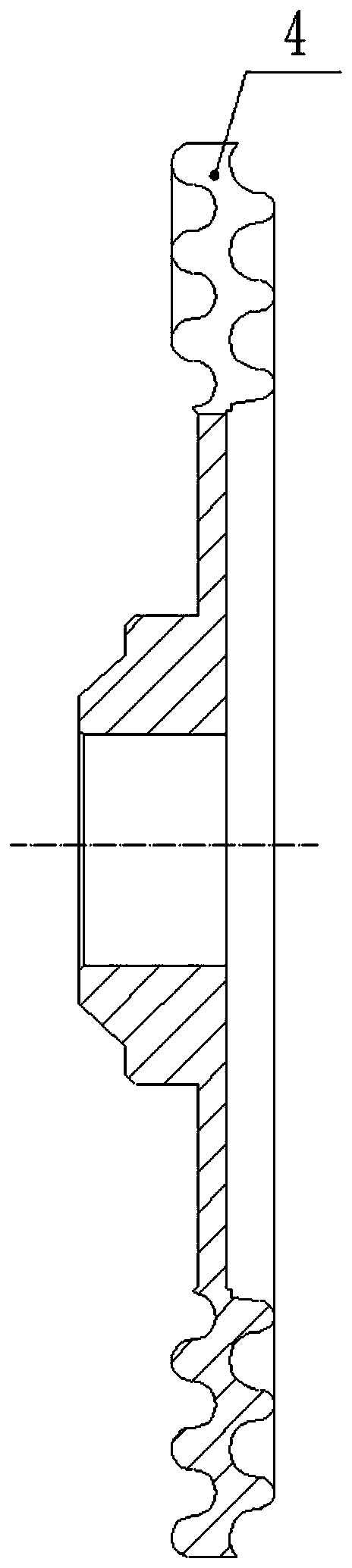

[0024] After the oil outlet 61 on the driven plate 6 is opened, the silicone oil flows out from the oil storage chamber 7 to the end cover 3, the active plate 4 and the housing 5 to form a closed spiral alveolar working chamber 8 after assembly, as figure 2 , image 3 , Figure 4 As shown, the silicone oil enters the oil storage chamber 7 through the oil return hole 31 on the end cover 3, and the silicone oil clutch operates stably at high speed;

[0025] When the oil outlet 61 on the driven plate 6 is closed, the silicone oil will no longer flow out from the driven plate 6, and the silicone oil in the curved alveolar working cavity 8 can be separated quickly due to its good fluidity in the curved alveolar. The oil return time is reduced, which ensures the stable operation of the silicone oil clutch at low speed.

[0026] Such as Figure 5 Shown is the prior art, the alveolar in the working chamber is a rectangular alveolar, the silicone oil flow is blocked and reduced, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com