Hydrogen energy power generation system of metal hydrogen storage material

A technology for hydrogen storage materials and power generation systems, which is applied to machines/engines, steam engines, mechanical equipment, etc., can solve the problems of small generator power generation, low system energy conversion rate, limited promotion value, etc., and achieve economic benefits. , the effect of energy saving and emission reduction economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

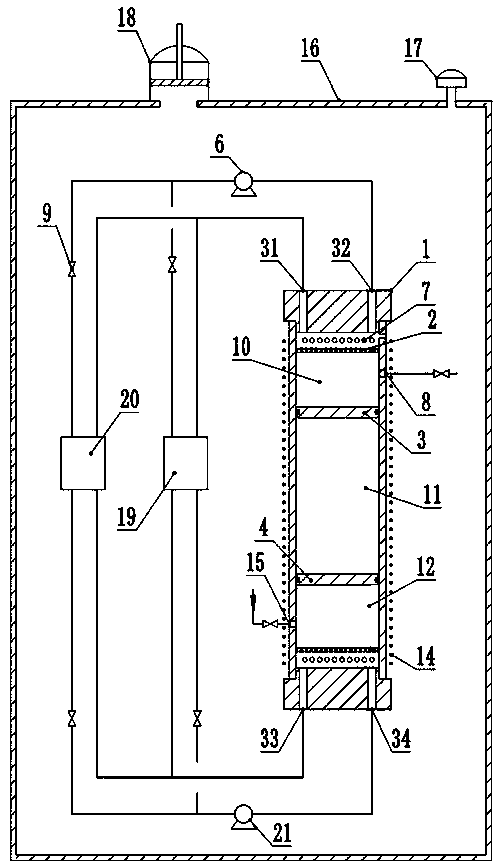

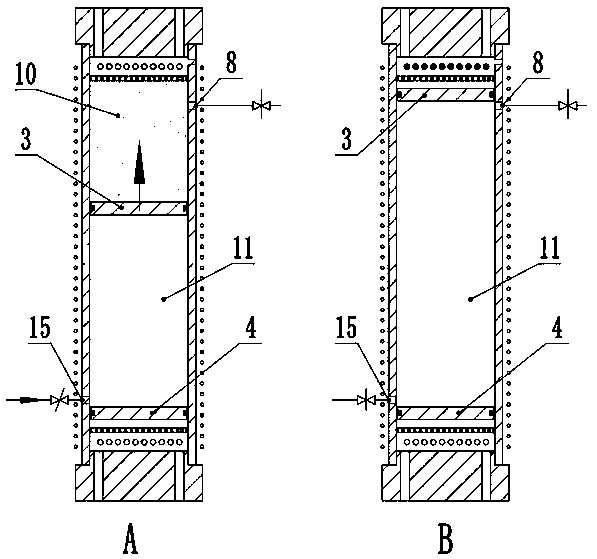

[0027] Metal hydrogen storage material hydrogen power generation system of the present invention such as figure 1 As shown, it includes a generator cylinder 1 , a heat accumulator 19 and a cold accumulator 20 . The generator cylinder 1 includes an upper end cover, a lower end cover and a cylinder body. The cylinder body is provided with a nitrogen gas inlet 15 and a nitrogen gas outlet 8. A generator coil 14 is wound outside the cylinder body, and the generator coil is connected to an external grid. The interior of the cylinder is provided with an upper piston 3 and a lower piston 4 of a permanent magnet structure, and the upper piston and the lower piston divide the cylinder into a telescopic upper hydrogen chamber 10 , a nitrogen chamber 11 and a lower hydrogen chamber 12 . The upper end cover is provided with an upper hydrogen outlet 31 and an upper hydrogen inlet 32 , and the lower end cover is provided with a lower hydrogen outlet 33 and a lower hydrogen inlet 34 . The...

Embodiment 2

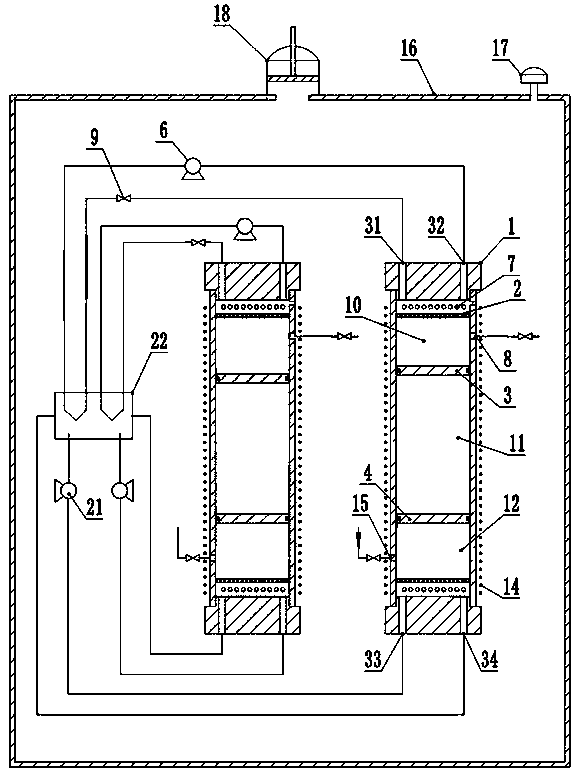

[0043] Another embodiment of the present invention is as figure 2 As shown, two generating cylinders 1 and a heat exchange center 22 are included. The upper hydrogen outlet 31 of the two generator cylinders 1 is connected to the heat exchange center 22, the connecting pipeline is provided with a valve, the heat exchange center 22 is connected to the upper hydrogen inlet 32 through the upper hydrogen circulation pump 6, and the outlet pipeline of the heat exchange center 22 is provided with Valve 9. The lower hydrogen outlet 33 is connected to the heat exchange center 22, the connecting pipeline is provided with a valve, the heat exchange center 22 is connected to the lower hydrogen inlet 34 through the lower hydrogen circulation pump 21, and the outlet pipeline of the heat exchange center 22 is provided with a valve 9. Other structures of this embodiment are the same as those of Embodiment 1.

[0044] Two sets of generator cylinder structure are adopted, and the working p...

Embodiment 3

[0048] In another embodiment of the present invention, only the hydrogen absorption and desorption conditions of the upper and lower metal hydrogen storage materials are changed, and other structures and working principles are the same as those in Embodiment 2.

[0049] In this embodiment, the hydrogen absorption pressure of the upper metal hydrogen storage material is 0.1MPa, the hydrogen absorption temperature is 20°C, the hydrogen release pressure is 0.025MPa, and the hydrogen release temperature is -20°C. The hydrogen absorption pressure of the lower metal hydrogen storage material is 0.02MPa, the hydrogen absorption temperature is -18°C, the hydrogen release pressure is 0.11MPa, and the hydrogen release temperature is 18°C. The heat is balanced through the internal heat exchange of the heat exchange center 22 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com