Scroll compressor with sealing assembly with silencing structure and fixedly connected with diaphragm plate

A technology of scroll compressors and sealing components, applied in the field of compressors, can solve problems such as leakage and reduce the working efficiency of compressors, and achieve the effect of improving working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

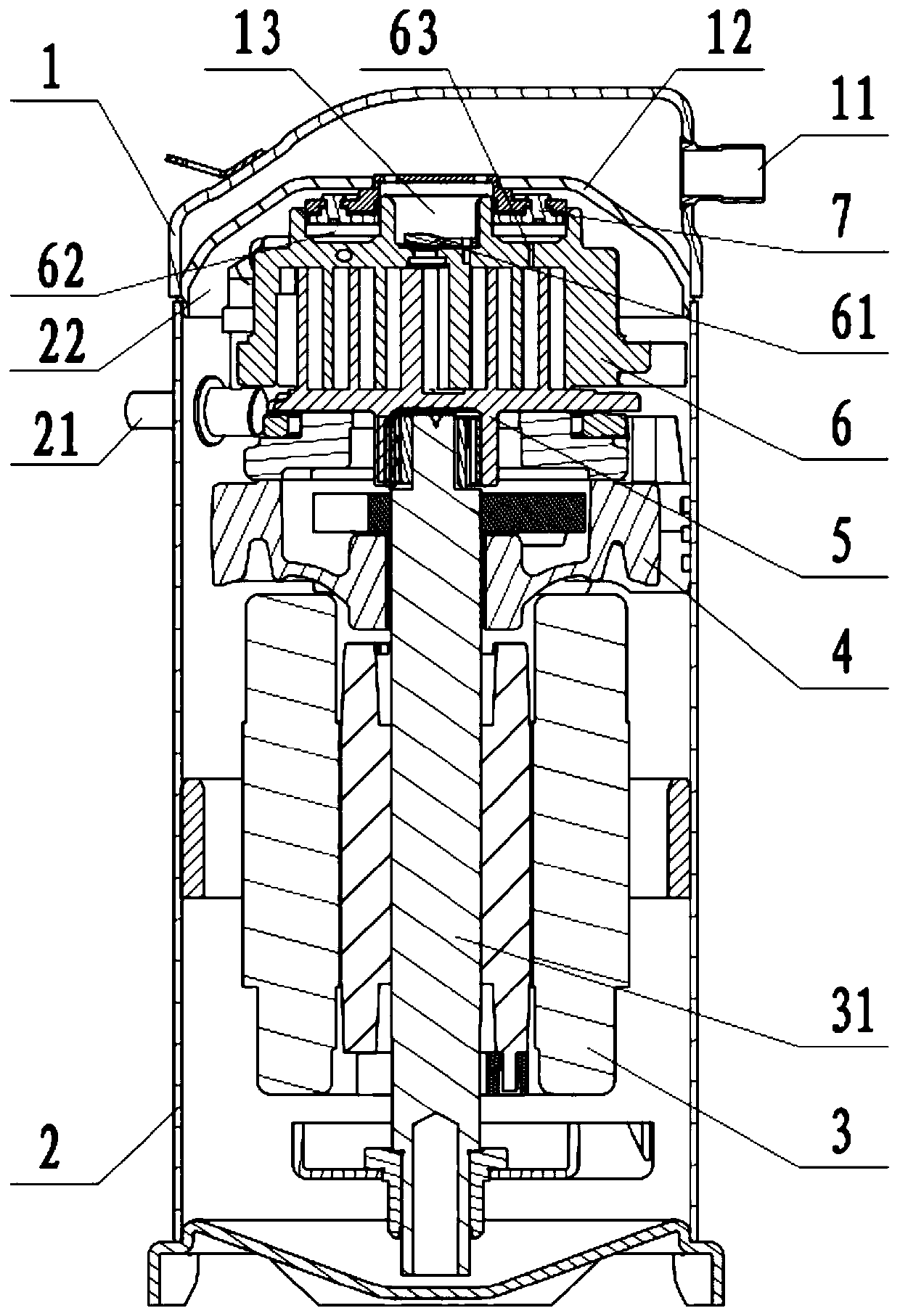

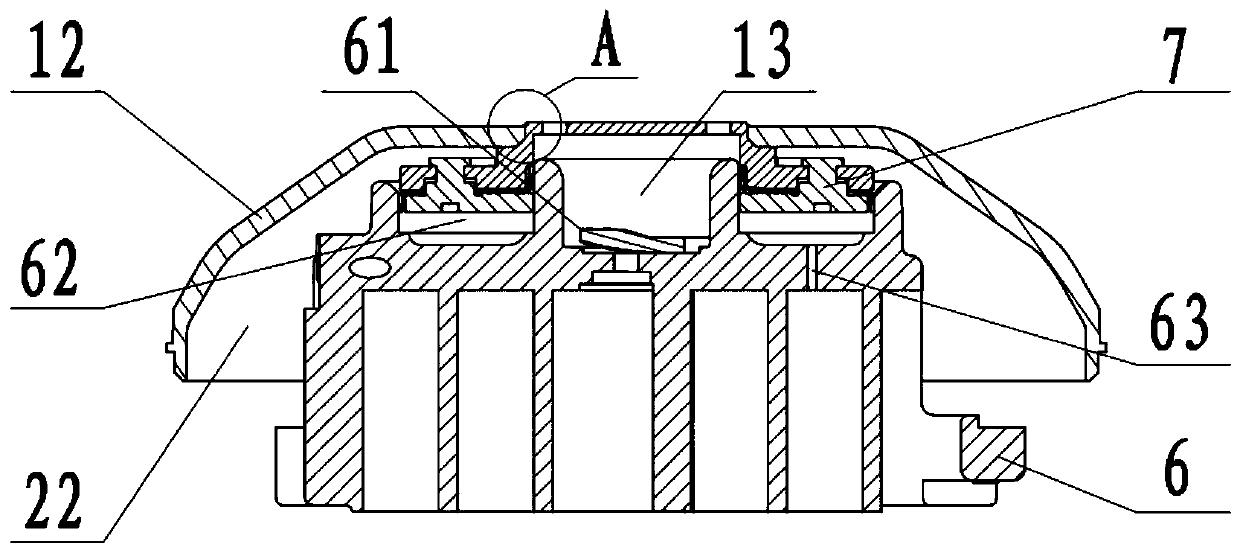

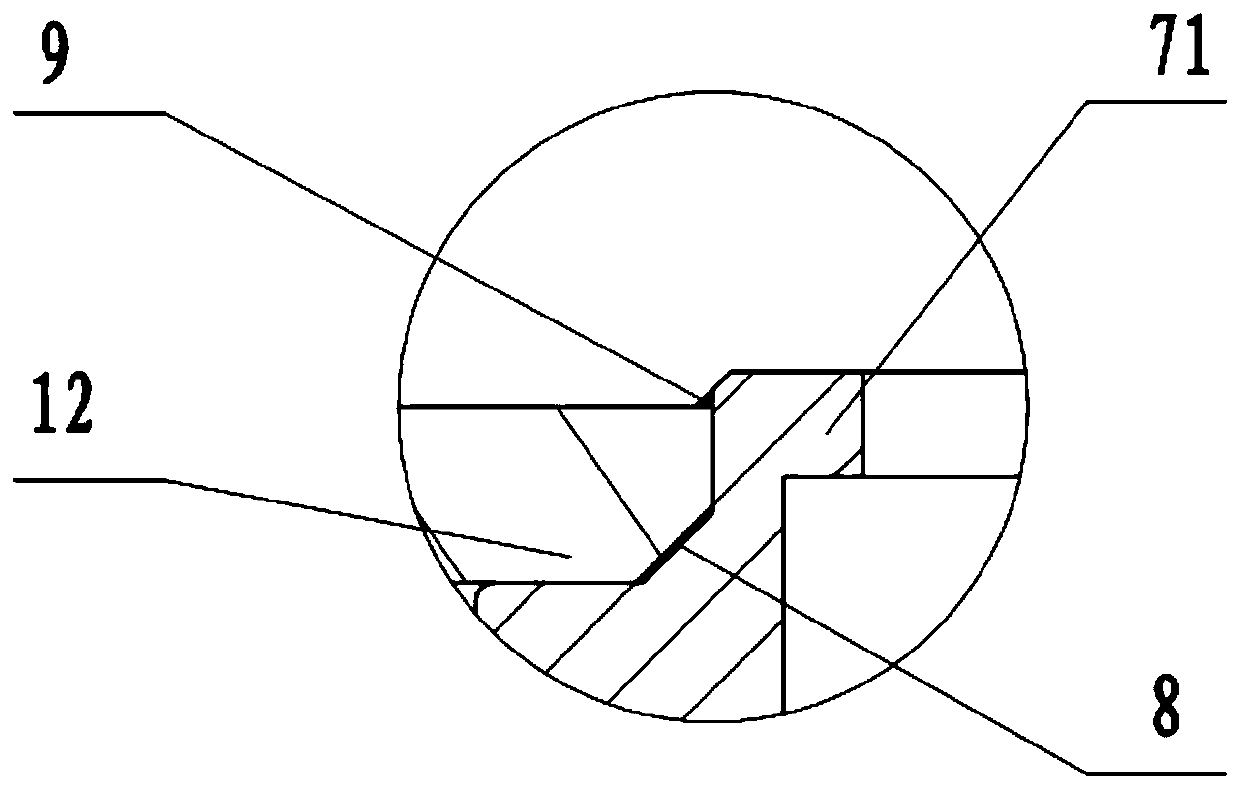

[0024] see Figure 1 to Figure 6 , a scroll compressor with a sealing assembly of a sound-absorbing structure and fixed to the diaphragm, including an upper casing 1, a lower casing 2, a motor 3, a main bearing 4, a movable scroll 5, a static scroll 6 and a sealing assembly 7 . The upper casing 1 includes an air outlet 11 and a diaphragm 12, the lower casing 2 includes an air inlet 21, and the motor 3, the main bearing 4, the movable scroll 5 and the fixed scroll 6 are all in contact with each other. In the low-pressure chamber 22 that the air inlet 21 communicates with. The fixed scroll 6 is limited in the circumferential direction, and there is a small gap in the axial direction to realize axial floating. The upper side of the movable scroll 5 is coupled with the lower side of the fixed scroll 6 to form at least one pair of compression chambers. The motor 3 is fixedly installed in the lower housing 1 through the outer ring of the motor stator and the main bearing 4, the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com