Lubricating oil filter for aeroengine

A technology for using lubricating oil in aero-engines, which is applied in the direction of engine lubrication, engine components, aircraft parts, etc., and can solve problems such as high viscosity of lubricating oil and false alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

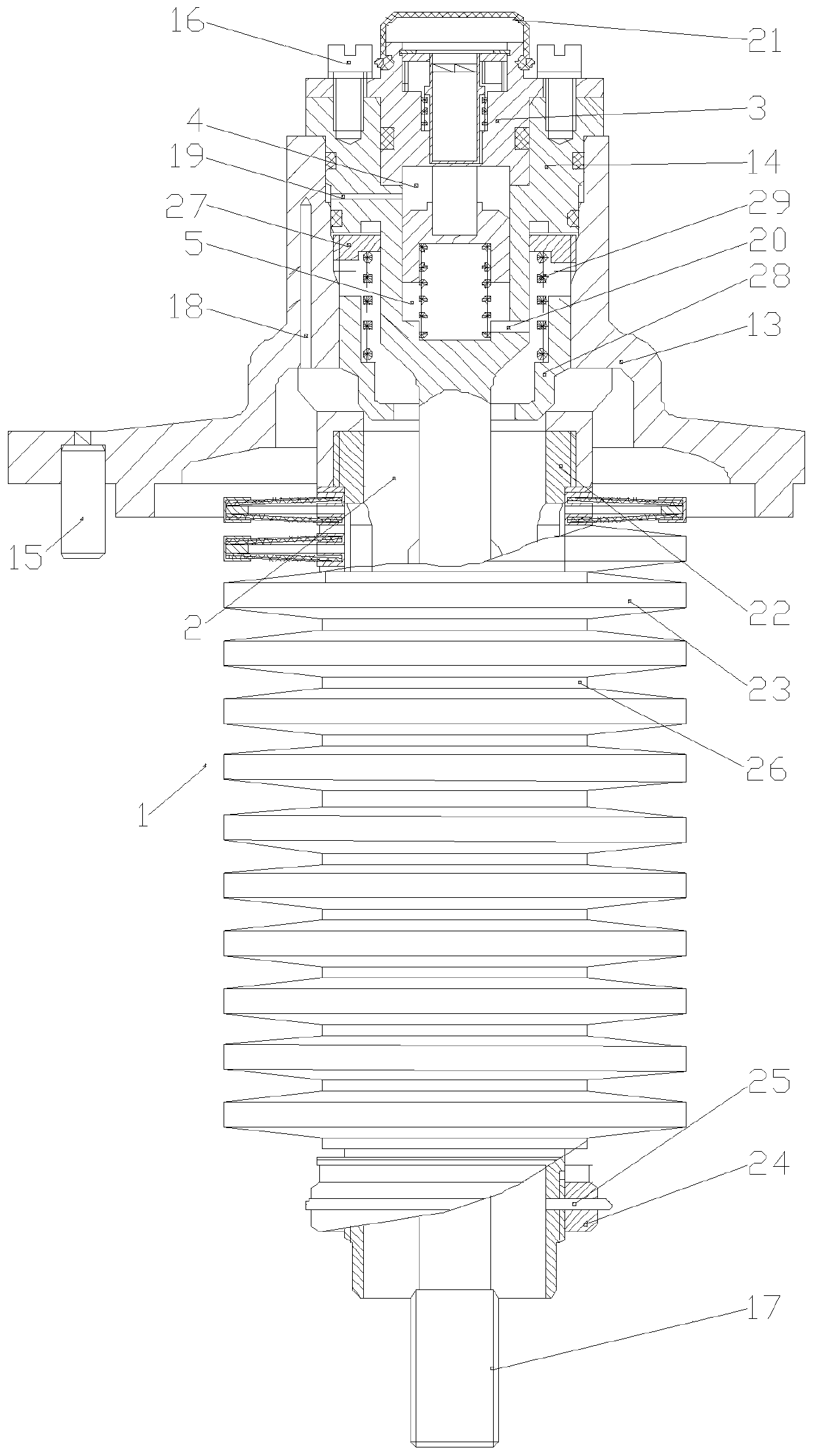

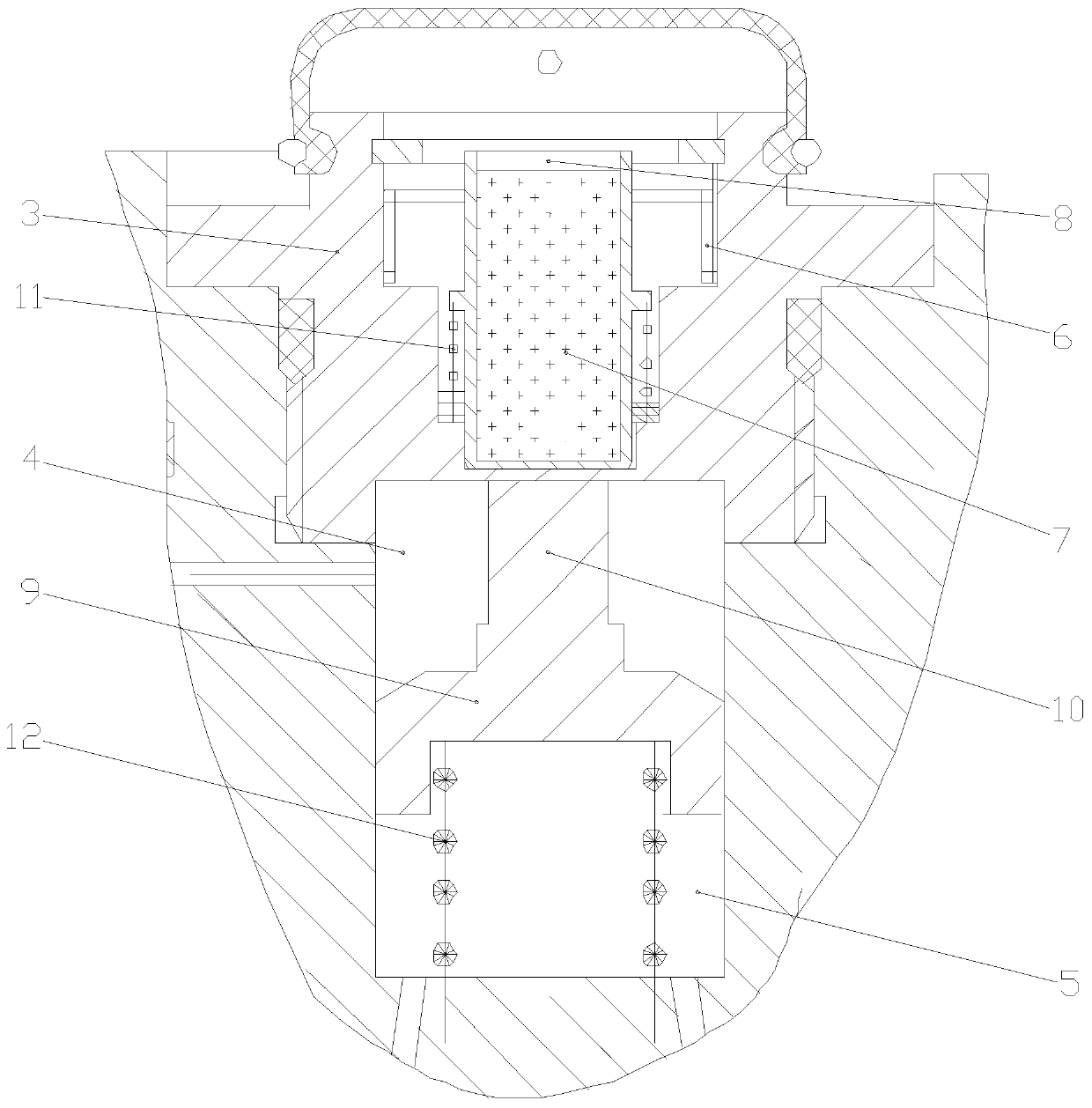

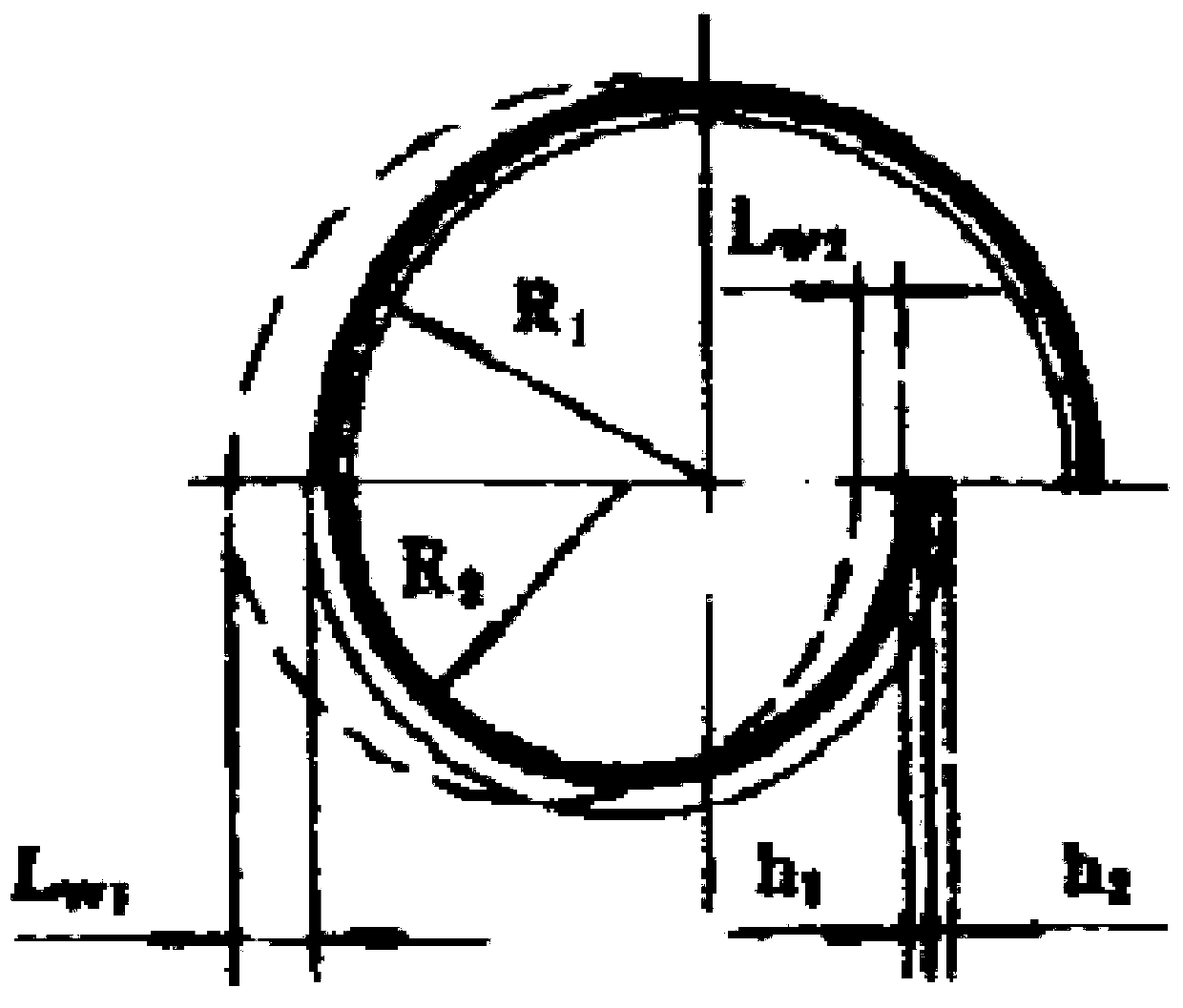

[0026] figure 1 It is a schematic diagram of an aero-engine lubricating oil filter in a preferred embodiment of the present invention; figure 2 is a schematic diagram of a differential pressure signal component and a temperature lockout component in a preferred embodiment of the present invention; image 3 is a schematic diagram of a bimetallic strip in a preferred embodiment of the present invention.

[0027] Such as figure 1 As shown, the aero-engine lubricating oil filter of this embodiment includes a filter assembly for being installed in the lubricating oil filter installation hole on the aero-engine and a sealing assembly for being installed outside the lubricating oil filter installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com