Automatic water replenishing equipment for steam boiler

A technology for automatic water replenishment and steam boilers, which is applied in steam generation, lighting and heating equipment, and water supply control. It can solve the problems of boiler water temperature drop, steam supply cut-off, and difficulty in meeting industrial production. It achieves small water level fluctuations and responsiveness. Fast, adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

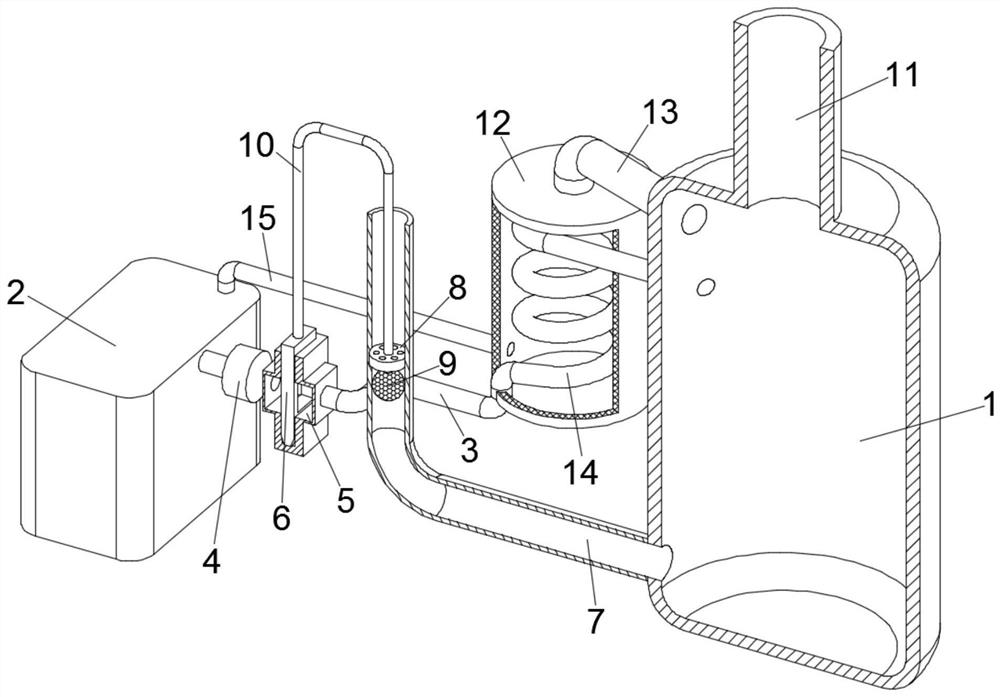

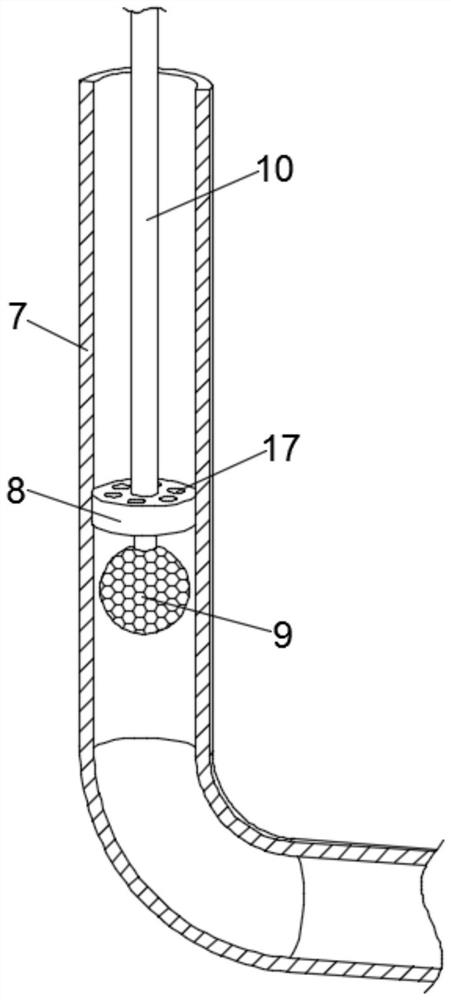

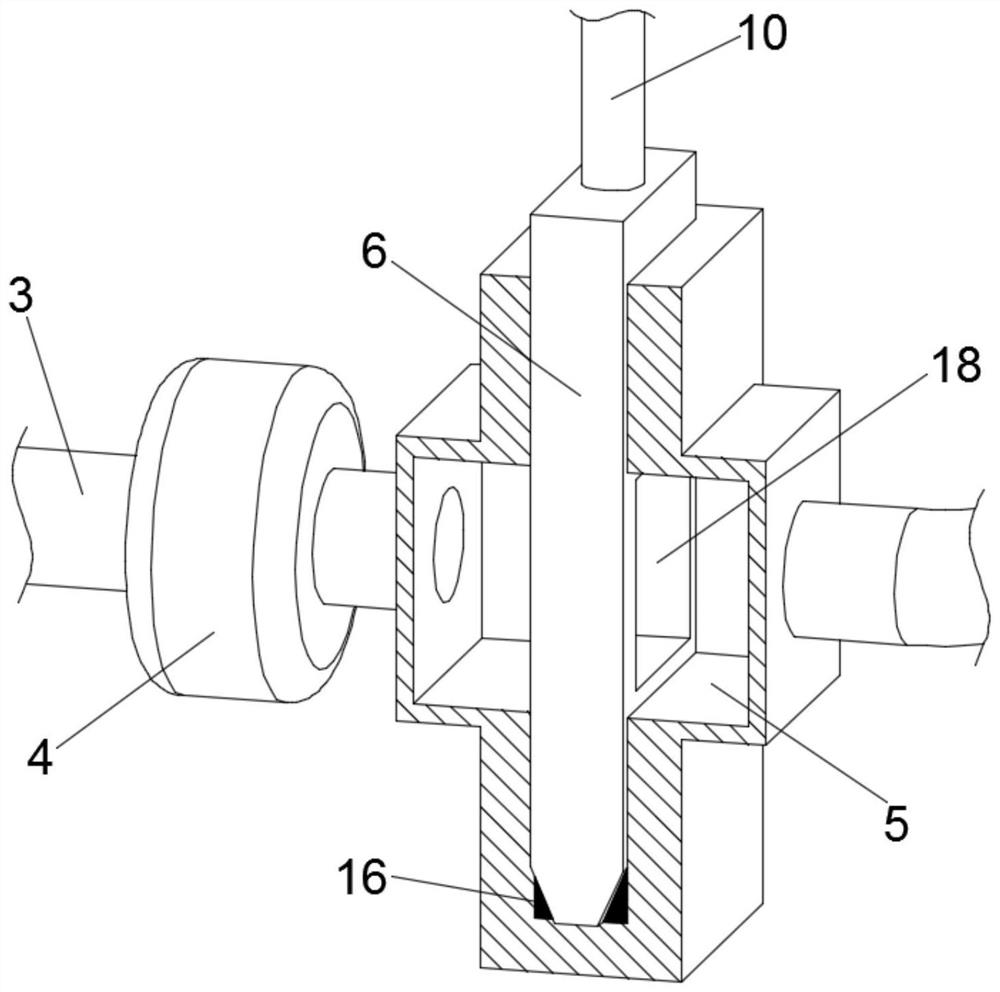

[0027] see figure 1 , a steam boiler automatic water replenishment equipment, including a boiler 1 and a water replenishment tank 2, the top of the boiler 1 is provided with a main steam pipe 11, and a water replenishment pipe 3 is connected between the water replenishment tank 2 and the boiler 1, and the water replenishment pipe 3 A water pump 4 and a chamber 5 are installed near one end of the replenishing water tank 2, and a sealing plate 6 is installed in the movable card of the chamber 5, and an adjusting hole 18 is opened on the sealing plate 6, and a valve is installed on the side wall of the boiler 1 An adjustment assembly controlling the channel size of the adjustment hole 18 on the sealing plate 6, the adjustment assembly includes a communication pipe 7, a sleeve plate 8 and a floating ball 9, the communication pipe 7 is fixed on the outer wall of the boiler 1 and communicates with the interior of the boiler 1, The vertical movable sleeve in the connecting pipe 7 is ...

Embodiment 2

[0037]An automatic water replenishment device for a steam boiler, comprising a boiler 1 and a water replenishment tank 2, a main steam pipe 11 is provided on the top of the boiler 1, a water replenishment pipe 3 is connected between the water replenishment tank 2 and the boiler 1, and the water replenishment pipe 3 is close to One end of the water supply tank 2 is installed with a water pump 4 and a chamber 5, and a sealing plate 6 is installed on the movable card in the chamber 5, and an adjusting hole 18 is opened on the sealing plate 6, and a control hole 18 is installed on the side wall of the boiler 1. An adjustment assembly for adjusting the channel size of the adjustment hole 18 on the sealing plate 6. The adjustment assembly includes a communication pipe 7, a sleeve plate 8 and a floating ball 9. The communication pipe 7 is fixed on the outer wall of the boiler 1 and communicates with the interior of the boiler 1. A sleeve plate 8 is vertically movable in the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com