Plate-tube type indirect evaporative cooling and evaporative condensation collaborative coupling water chilling unit

A chiller, evaporative cooling technology, applied in water shower coolers, indirect heat exchangers, fixed conduit components, etc. The effect of spraying water temperature, improving indirect evaporative cooling efficiency and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the drawings and specific embodiments.

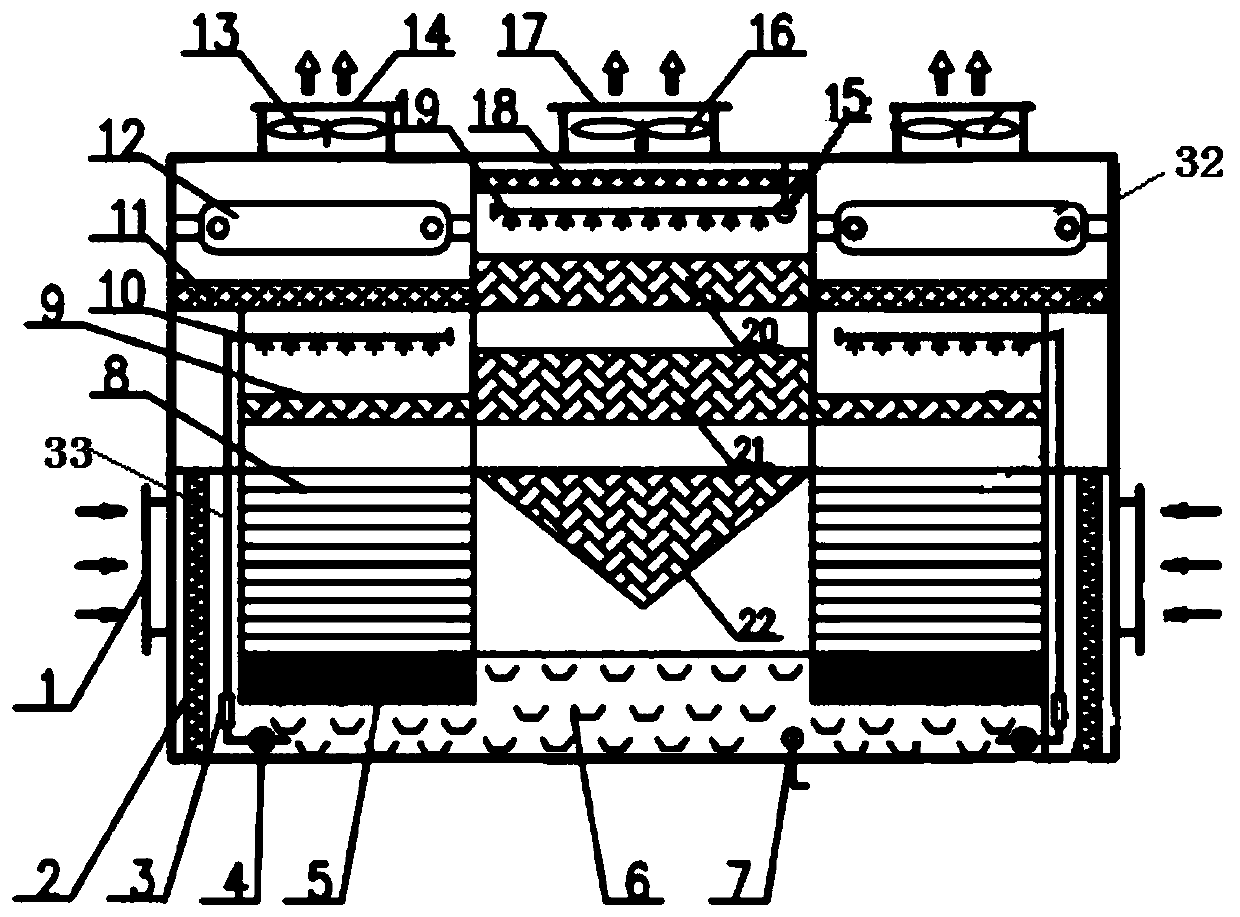

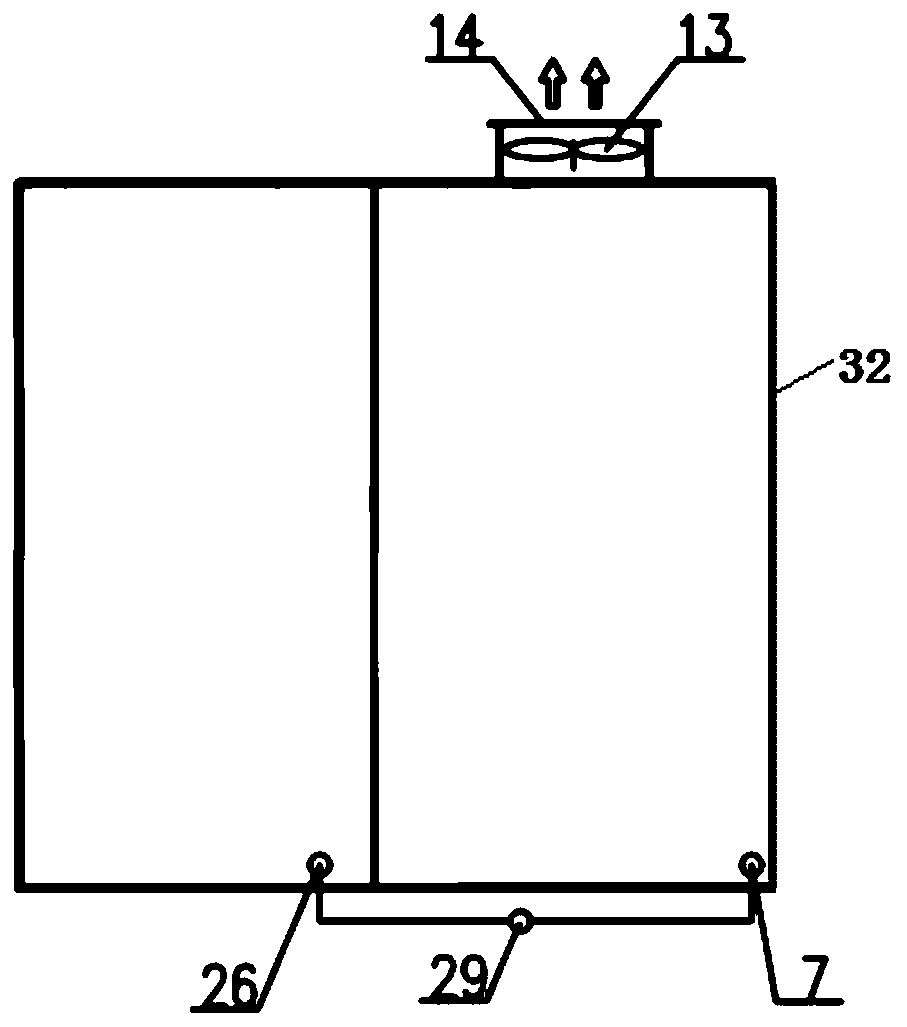

[0030] The present invention is a plate-tube type indirect evaporative cooling and evaporative condensation cooperatively coupled chiller, such as figure 1 As shown, the casing 32 is included. The middle of the casing 32 is provided with a packing tower unit. The structures on the left and right sides of the packing tower unit are symmetrical and the same to ensure that the chiller can take in air from both sides, including the air inlet 1 arranged on the side wall. The housing 32 in the tuyere 1 is sequentially provided with an air filter 2, an evaporative cooling unit, a water baffle a11, a direct expansion refrigeration unit, an exhaust fan a13, and an exhaust port a14 according to the air flow direction.

[0031] Among them, the air filter 2 adopts a coarse-effect plate air filter.

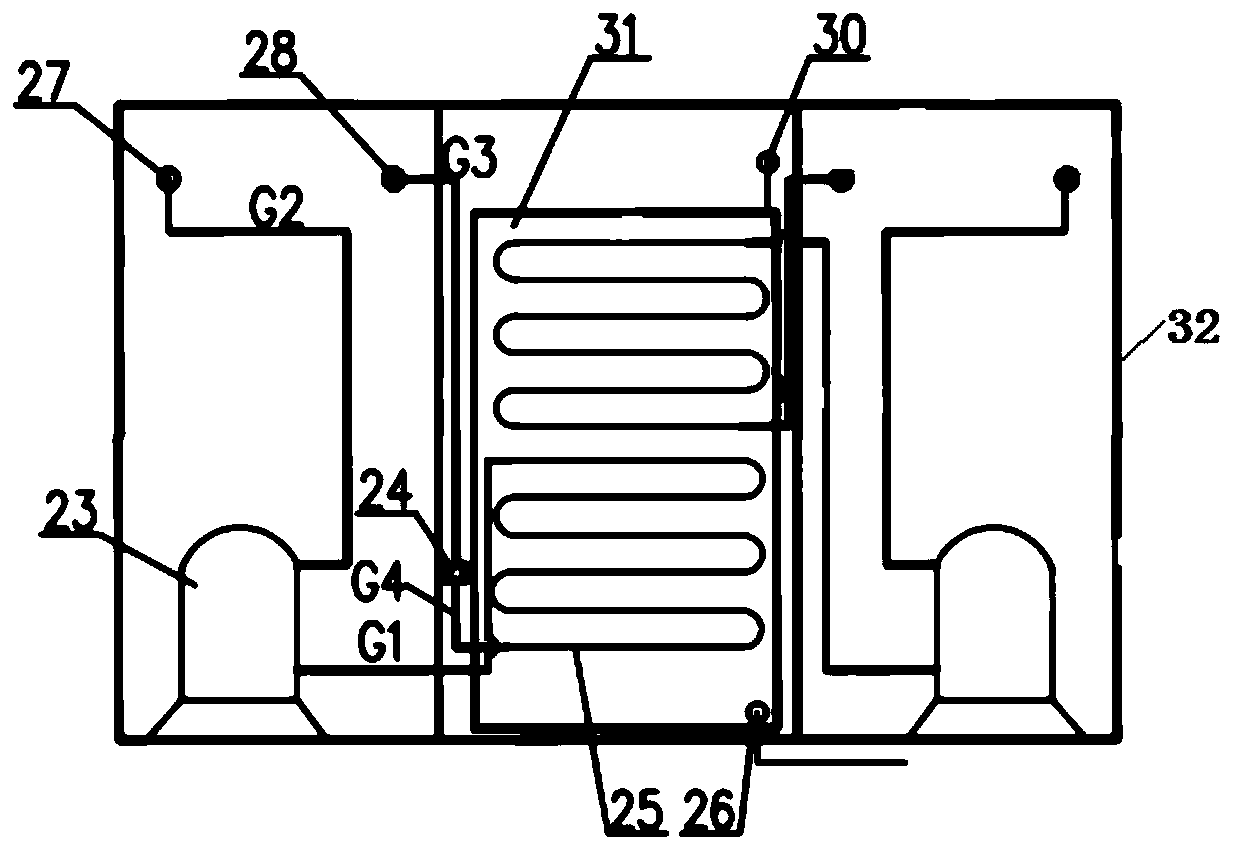

[0032] The evaporative cooling unit includes a plate and tube type indirect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com