Demisting and cooling integrated heat exchange tubes, demisting and cooling integrated heat exchange device and application thereof

A technology of heat exchange tubes and shells, applied in the field of demisting devices, which can solve the problems of large space occupation, high investment, and large fan output, and achieve the effects of reducing relative humidity, reducing flue gas temperature, and promoting condensation and precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

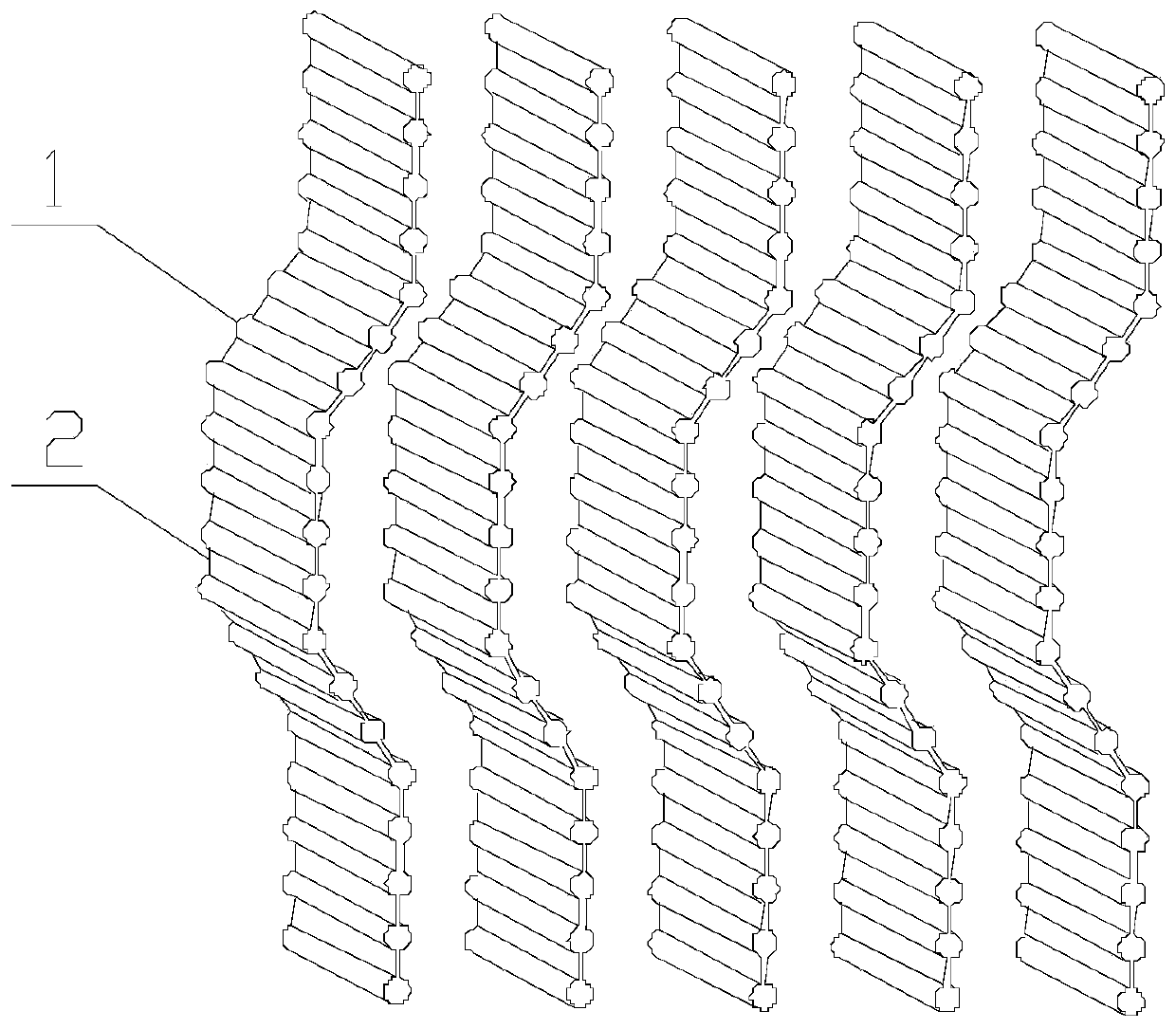

[0046] An integrated heat exchange tube for demisting and cooling, refer to figure 1 , which includes: heat exchange tubes 1 and connection plates 2, the heat exchange tubes 1 and connection plates 2 are distributed alternately, and the outer walls of the heat exchange tubes 1 and the outer surfaces of the connection plates are connected together to form a wave-shaped plate Structure; that is, every two adjacent heat exchange tubes are connected together by a connecting plate, and the nozzles of each heat exchange tube face the same direction.

Embodiment 2

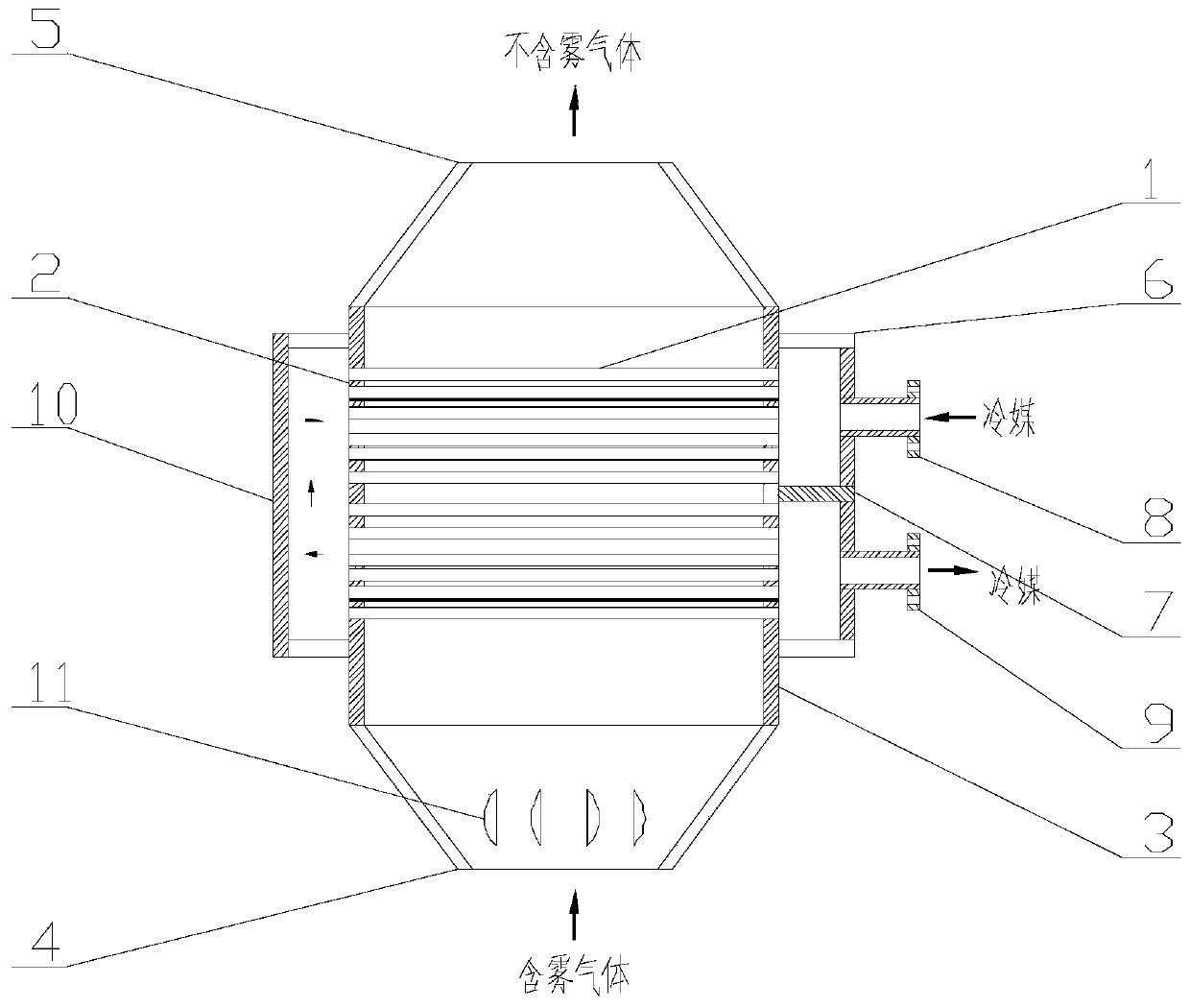

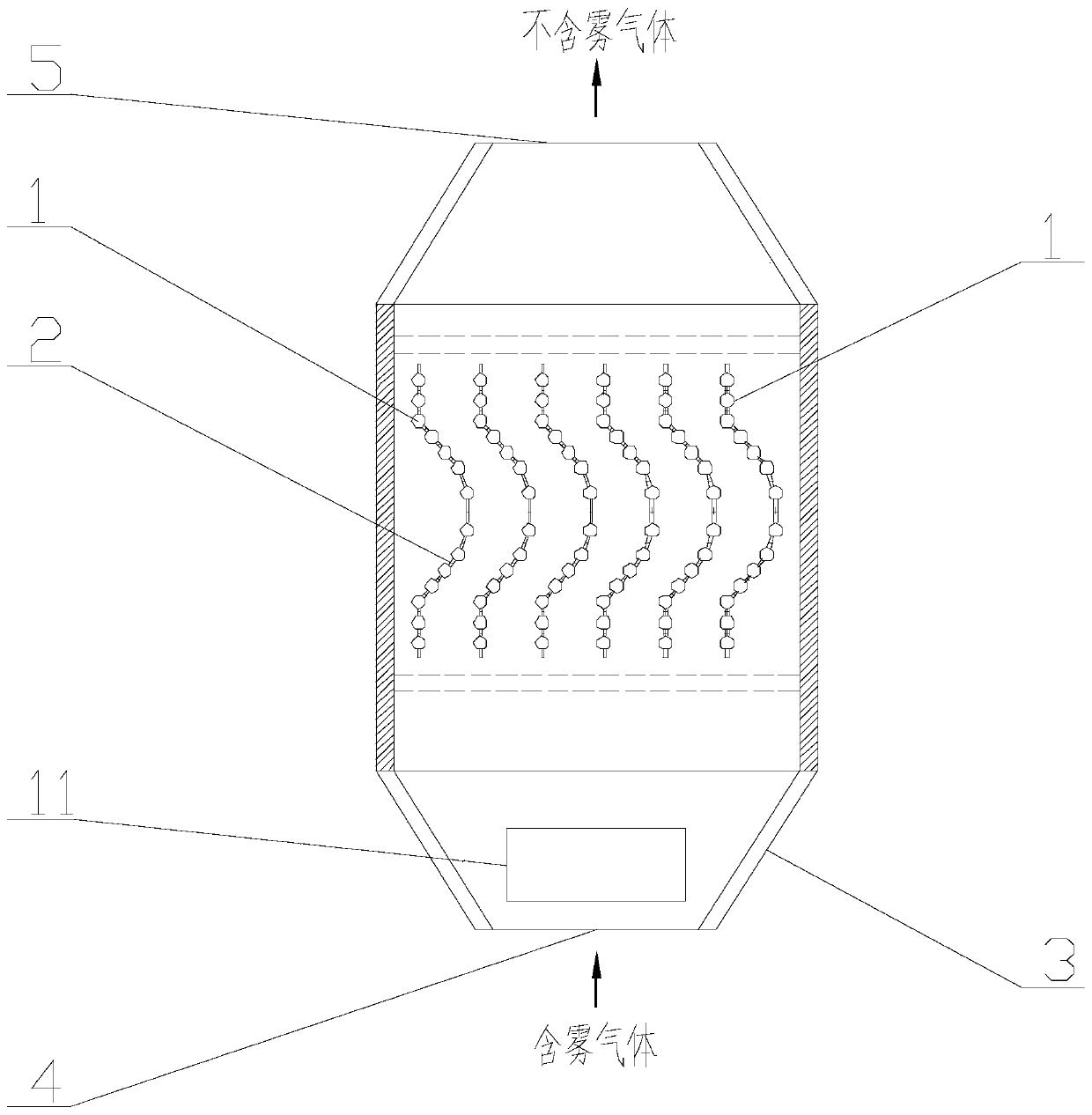

[0048] A vertical demisting and cooling integrated device, refer to figure 2 and 3 , which includes: the defogging and cooling integrated heat exchange tube in Example 1, a shell 3, a flue gas inlet 4, a flue gas outlet 5, a header 6, a header partition 7, a refrigerant inlet 8, and a refrigerant outlet 9 and coupler 10, where:

[0049] The housing 3 is arranged vertically, and the lower and upper ends of the housing 3 are the smoke inlet 4 and the smoke outlet 5 respectively. The tank partition 7 separates the header into upper and lower chambers; the refrigerant inlet 8 and the refrigerant outlet 9 are respectively arranged on the upper and lower chambers; the coupling 10 is arranged on the outer wall of the housing 3 and Located on the opposite side of the header 6; the integrated heat exchange tube for defogging and cooling is located in the housing 3, and the two ends of the heat exchange tube 1 are respectively connected with the header 6 and the coupler 10, that is, ...

Embodiment 3

[0051] A horizontal demisting and cooling integrated device, comprising: the demisting and cooling integrated heat exchange tube in Embodiment 1, a shell 3, a flue gas inlet 4, a flue gas outlet 5, a header 6, a header compartment Plate 7, refrigerant inlet 8, refrigerant outlet 9, coupling 10 and condensate outlet 12, where:

[0052] The housing 3 is arranged horizontally, and the left and right ends of the housing 3 are respectively the smoke inlet 4, the smoke outlet 5 or the smoke outlet 5, and the smoke inlet 4, and the lower wall of the housing 3 has a clip with respect to the horizontal plane. The condensed water outlet 12 is arranged on the lower wall of the casing 3 and is located on the lower side.

[0053] The header 6 is arranged on the outer wall of the housing 3, and the header 6 is provided with a header partition 7 to divide the header into upper and lower chambers; the refrigerant inlet 8 and the refrigerant outlet 9 are respectively arranged on the On the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com