Real-time online monitoring system for hydraulic metal structure equipment

A metal structure and monitoring system technology, applied in the direction of measuring devices, instruments, etc., can solve the problem of few monitoring data, long running time of hydraulic metal structure equipment, difficulty in grasping and estimating the dynamic balance of hydraulic metal structure equipment, etc. problems, to achieve the effect of saving monitoring and maintenance costs, improving monitoring and maintenance efficiency, and reducing the amount of processed data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

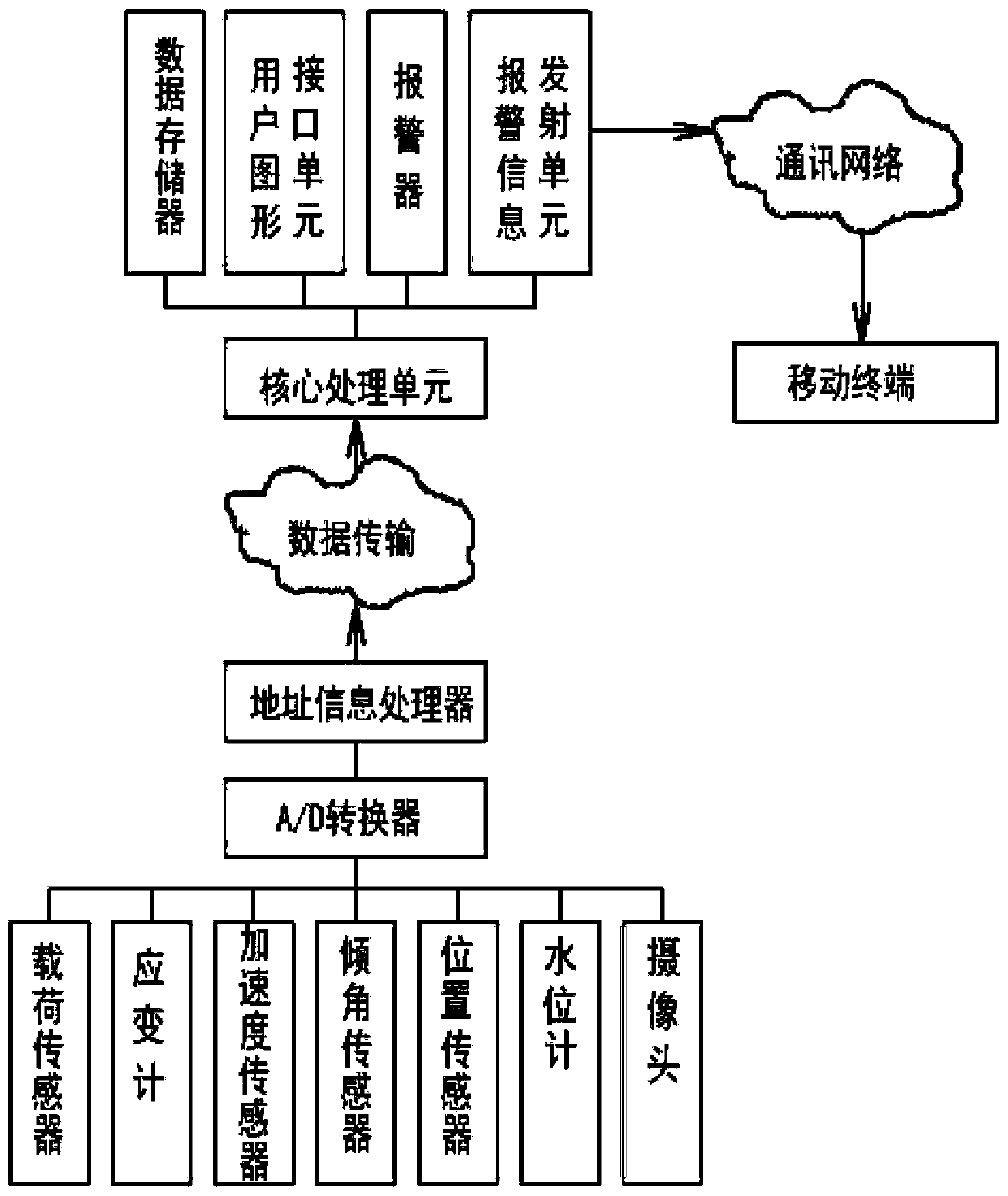

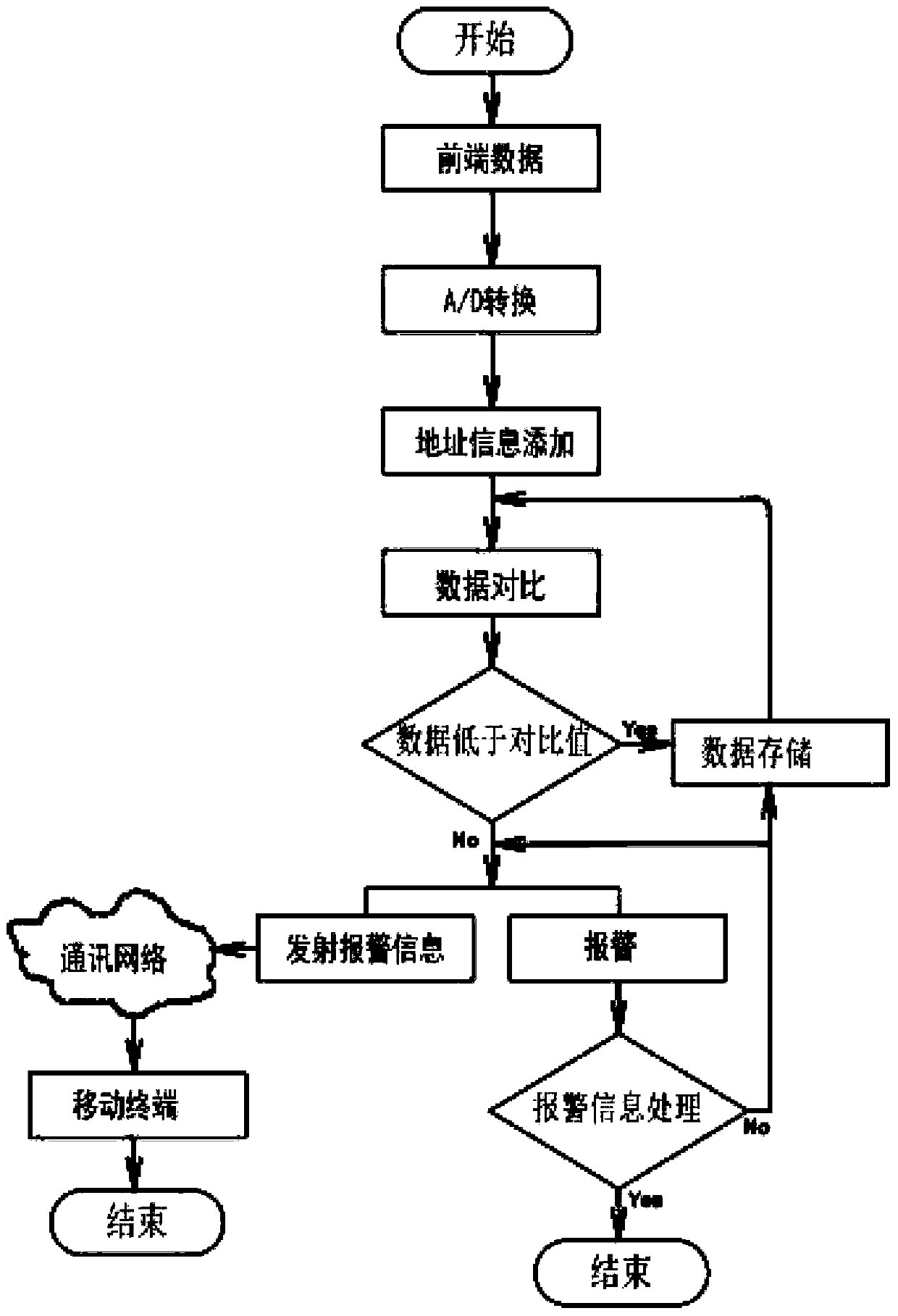

[0049] Embodiment: When the present invention implements monitoring, relevant information is transmitted to the data transmission part through front-end data acquisition parts such as load sensors, strain gauges, acceleration sensors, inclination sensors, position sensors, water level gauges, cameras, etc., and the data transmission part transmits relevant information Carry out classification, conversion and packaging processing, add the corresponding address information code of hydraulic metal structure equipment before the information in the packaging processing process, and then transmit it northward to the core processing server; the core processing server decodes the address information of the header after receiving the collected information Identify and send the information to the corresponding storage area for information storage, then compare the new and old information of the hydraulic metal structure equipment at the same address, compare the comparison result with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com