Core cementing mold for sand consolidation formula performance evaluation and experimental method of core cementing mold

A core and cementing technology, which is used in the preparation of test samples, testing the strength of materials by applying a stable bending force, and testing the strength of materials by applying a stable tension/compression. It can prevent internal cracks and cavities, the preparation method is simple, and the uniform expansion can be ensured.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention will be further described:

[0031] The core cemented mold for performance evaluation of this sand consolidation formula is prepared by the following methods:

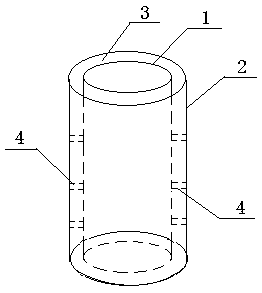

[0032] Firstly, the 3D structural diagram of the core cementation mold is drawn by the drawing software, which is in the shape of an annular cylinder. Refer to figure 1 , the core cementation mold is composed of an inner cylinder 1 and an outer cylinder 2 coaxially, the inner diameter of the inner cylinder 1 is 25mm, the outer diameter of the outer cylinder 2 is 50mm, and there are three fixing belts 4 connecting the inner cylinder 1 and the outer cylinder 2 in the annular space 3, Both ends of inner cylinder 1 are open, the upper end of annular space 3 is open, and the bottom end of annular space 3 is closed. Print the core cementation mold with ester material; fill the annular space 3 of the printed core cementation mold with dried sand par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com