Robot workstation for small automobile exhaust gas detection and detection method thereof

A technology for exhaust gas detection and small cars, which is applied in the direction of instruments, manipulators, measuring devices, etc., can solve the problem of lack of robot workstations, achieve the effects of shortening the detection preparation time, increasing the range of detection vehicles, and wide moving range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

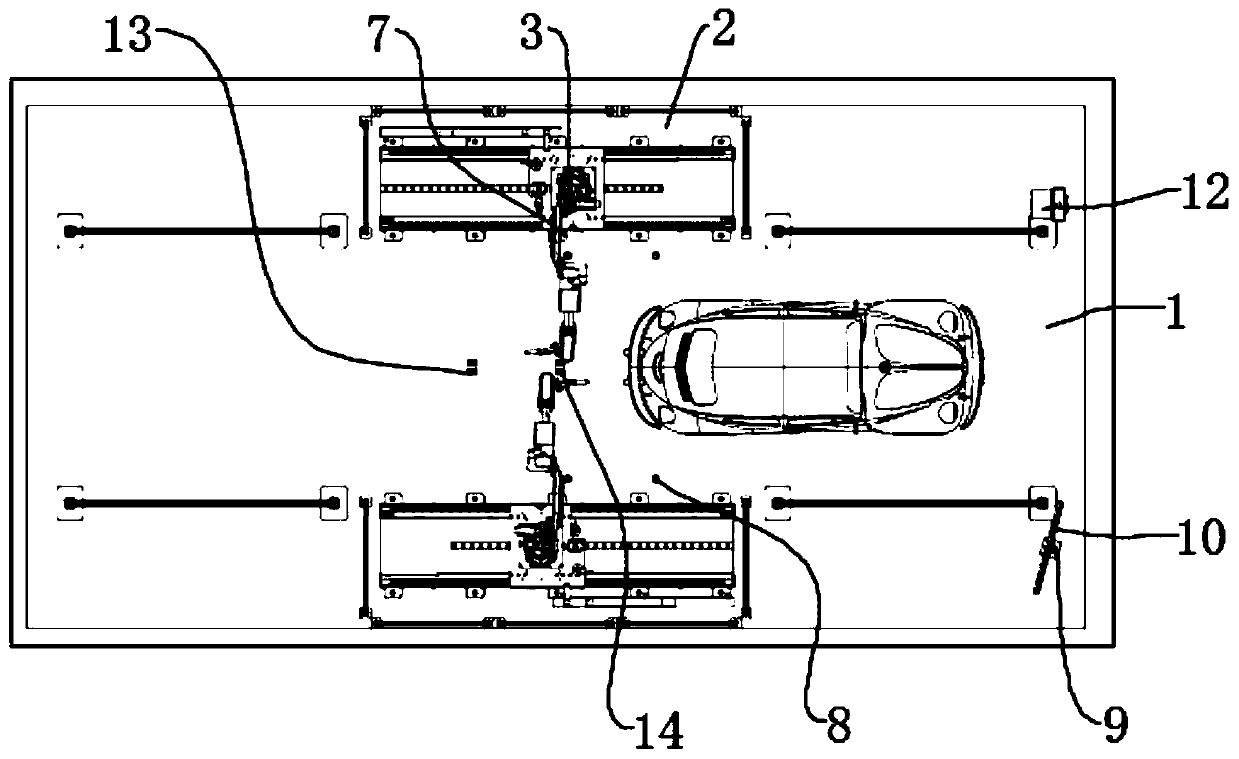

[0049] refer to Figure 1 to Figure 3 , a robot workstation for small vehicle exhaust detection, wherein the device includes:

[0050] A detection channel 1 for vehicle driving, the vehicle to be detected will be driven into the detection channel 1 and parked at a fixed-point position on the detection channel 1 for a period of detection;

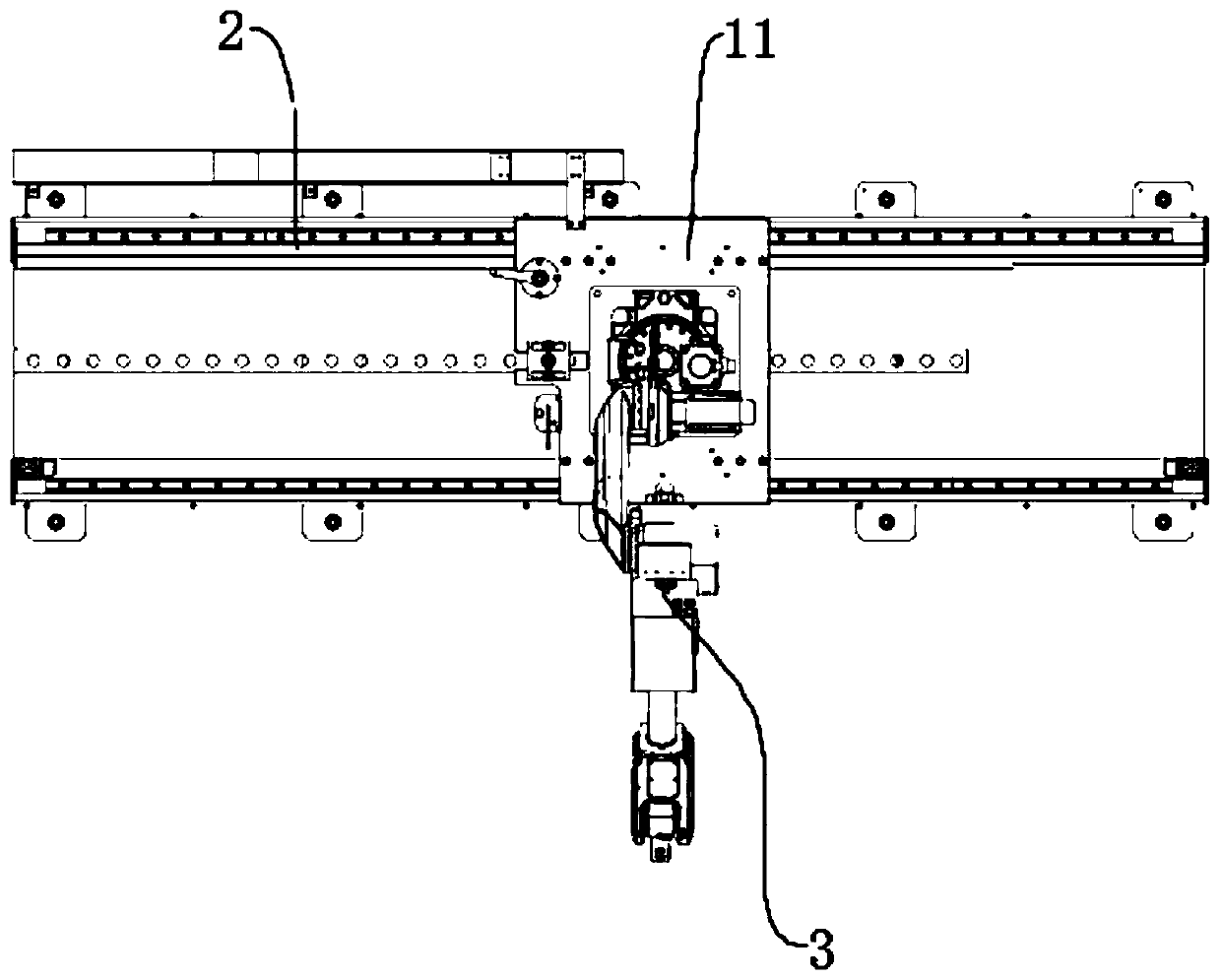

[0051] Two movable ground rails 2 located on both sides of the detection channel 1, the movable ground rails 2 can be easily disassembled to the detection channel 1, and its installation position can be adjusted;

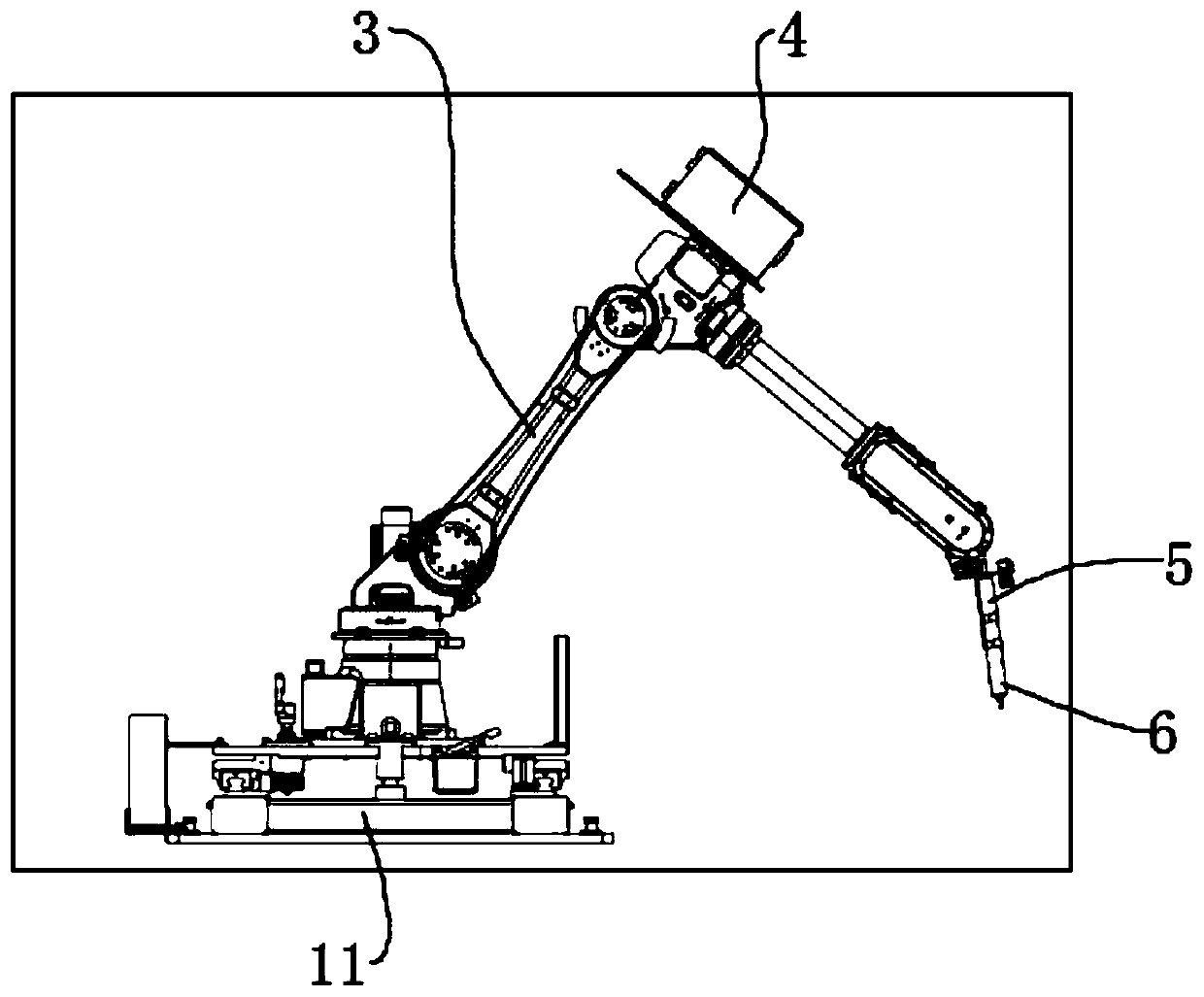

[0052] A location-seeking robot 3 slidingly connected to two movable ground rails 2, a detection tube conveyor 4 is arranged on the location-seeking robot 3, and the location-seeking robot 3 can slide on the movable ground rail 2 to adjust its position;

[0053] The sensor bracket 5 for position adjustment is driven by the detection tube conveyor 4, and the end of the sensor bracket 5 is connected with a detection sensor 6 for de...

Embodiment 2

[0061] The difference from Embodiment 1 is that a detection method for a robot workstation for small vehicle exhaust detection is also provided, which specifically includes the following steps:

[0062] S1. Drive the vehicle to be detected into the detection channel 1. After the vehicle to be detected stops, the signal indicator light 12 lights up in red, and the status display 10 shows that the detection starts;

[0063] S2. The detection sensor 6 detects the rear position of the vehicle to be detected;

[0064] S3. The visual recognition system detects the position of the exhaust pipe of the vehicle to be detected;

[0065] S4, the positioning robot 3 starts to move the manipulator to the exhaust pipe of the vehicle to be detected according to the instructions of the visual recognition system and the operation control system;

[0066] S5. The conveyor transports the sensor bracket 5 to the inside of the exhaust pipe, and after extending into the set length, the detection se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com