Connector for online current detection and its active terminal

A connector and source terminal technology, applied in the direction of electrical connection testing, components of electrical measuring instruments, voltage/current isolation, etc., can solve the problem of large size, the inability of the connector to integrate a current detection device, and the inability to realize online detection of the working current of the connector and other problems, to achieve the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

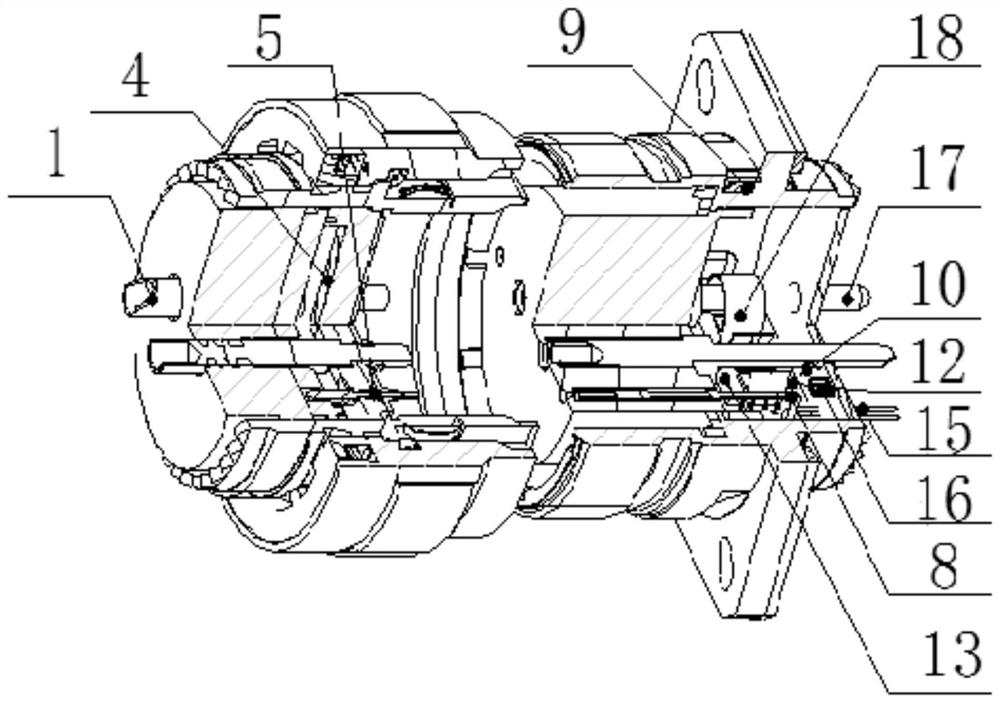

[0020] The following in conjunction with the accompanying drawings of a particular embodiment of the present invention will be further described.

[0021] Connector embodiment:

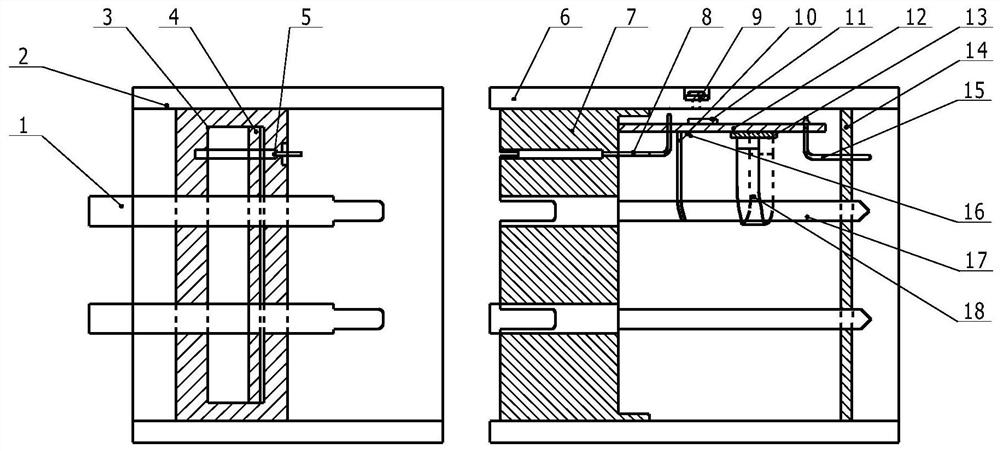

[0022] as Figure 1 The connectors shown, including active and passive ends, the active end is the connector socket, and the passive end is the connector plug. The active end comprises an active end housing 6, an active end front end insulator 7, an active end back end insulator 14, an active end signal contact 17, an active end auxiliary contact 8 and an active end printed board 12, the active end auxiliary contact 8 is fixed to the active end front end insulator 7, the active end auxiliary contact 8 is connected to the active end printed board 12 in the form of a curved needle.

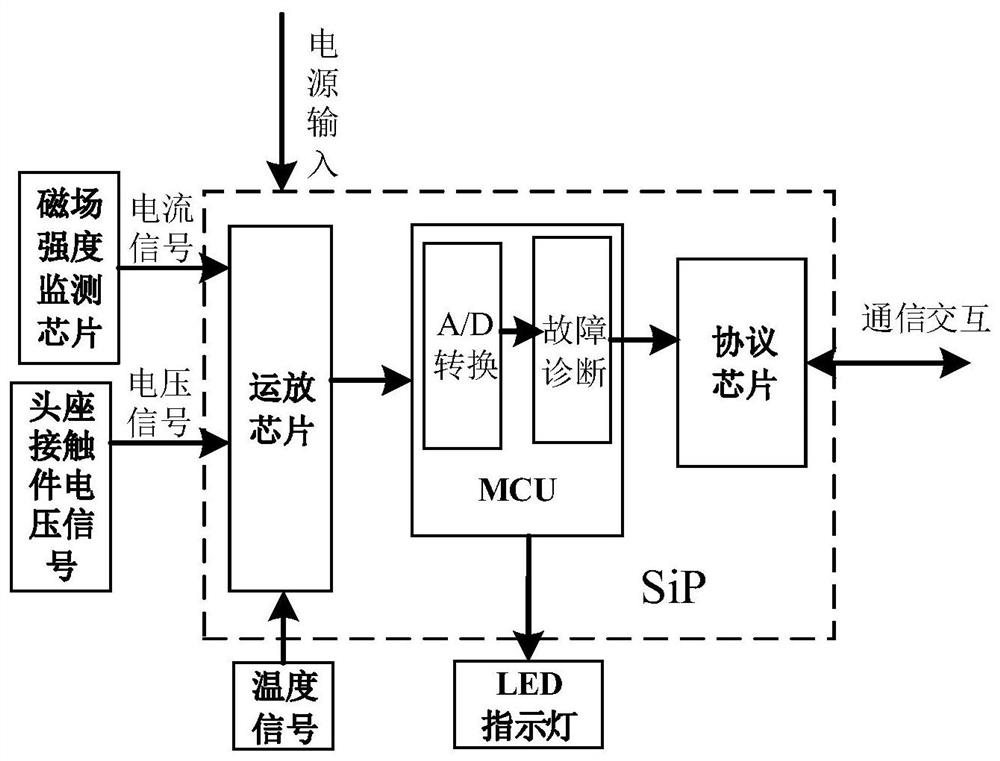

[0023] Active terminal printed board 12 is integrated with an active control chip 11, status indicator 9, current sensor 13, temperature sensor 16 and contact resistance detection circuit, the contact resistance detection circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com