Modification method of rubber particles and modified rubber concrete

A rubber particle and concrete technology, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problem of ineffective washing treatment of rubber particles, the optimal addition of silane solution, and the problem of silane modification. Solve problems such as complex polymer emulsion technology, achieve significant direct economic benefits, save maintenance and repair costs, and improve compressive strength and splitting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

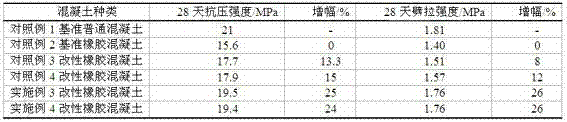

Examples

Embodiment 1

[0019] A method for modifying rubber particles: prepare an aqueous NaOH solution with a mass concentration of 18%; KH570 (silane coupling agent, liquid) takes 1% of the mass of rubber particles and dilutes it with ethanol to obtain a KH570 solution; soak the rubber particles in NaOH aqueous solution first After 24 hours, wash the rubber particles with water once, then fully wet the rubber particles with KH570 solution, dry them and store them for later use; the amount of ethanol is based on the amount of KH570 solution that can fully wet the rubber particles.

Embodiment 2

[0021] A method for modifying rubber particles: prepare NaOH aqueous solution with a mass concentration of 23%; KH570 (silane coupling agent, liquid) takes 1.3% of the mass of rubber particles and dilutes it with ethanol to obtain a KH570 solution; soak the rubber particles in NaOH aqueous solution first After 24 hours, wash the rubber particles with water for 3 times, then fully wet the rubber particles with KH570 solution, dry them and store them for later use; the amount of ethanol is based on the amount of KH570 solution that can fully wet the rubber particles.

[0022] Modified rubber concrete embodiment

Embodiment 3

[0024] Modified rubber concrete: rubber particles replace part of the sand by 10% equal volume, and the weight ratio is cement: water: sand: stone: rubber particles=340:210:594:1190:29.5, and the rubber particles are as described in Example 1 Method modification.

[0025] Mixing process:

[0026] 1) Weigh stones, cement, sand, rubber particles and water according to the mixing ratio;

[0027] 2) Add the stones into the mixing pot first, then mix the rubber particles into the cement and add them into the mixing pot together, then add sand, start the mixing pot and stir for 10 seconds, and finally add water and mix for 2min30s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com