Real-time optimization method and apparatus used for continuous reforming device

A reforming device and optimization method technology, applied in the field of data optimization, can solve problems such as affecting online real-time calculation and stability performance, sacrificing model extrapolation ability, and narrowing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

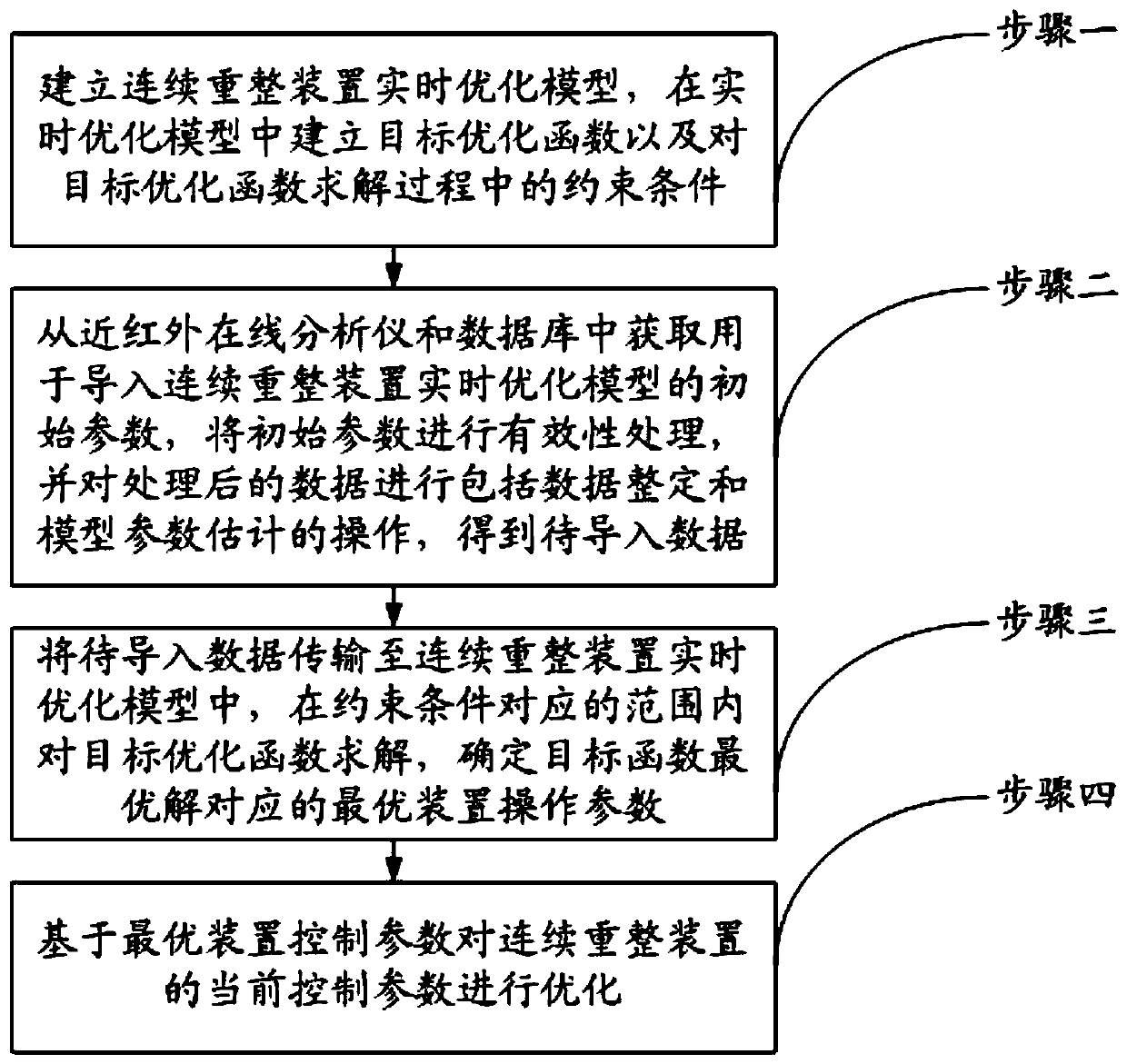

[0063] In order to solve the defects of the prior art, such as the difficulty in solution caused by too much reliance on the strict steady-state mechanism model, this embodiment proposes a real-time optimization method for continuous reforming devices based on the combination of simplified mechanism and deep neural network model, specifically as figure 1 As shown, the real-time optimization method includes:

[0064] Step 1, establishing a real-time optimization model of the continuous reforming unit, establishing an objective optimization function and constraints in the process of solving the objective optimization function in the real-time optimization model;

[0065] Step 2: Obtain the initial parameters used to import the real-time optimization model of the continuous reforming unit from the near-infrared online analyzer and the database, process the initial parameters for validity, and perform data adjustment and model parameter estimation on the processed data Operation t...

Embodiment 2

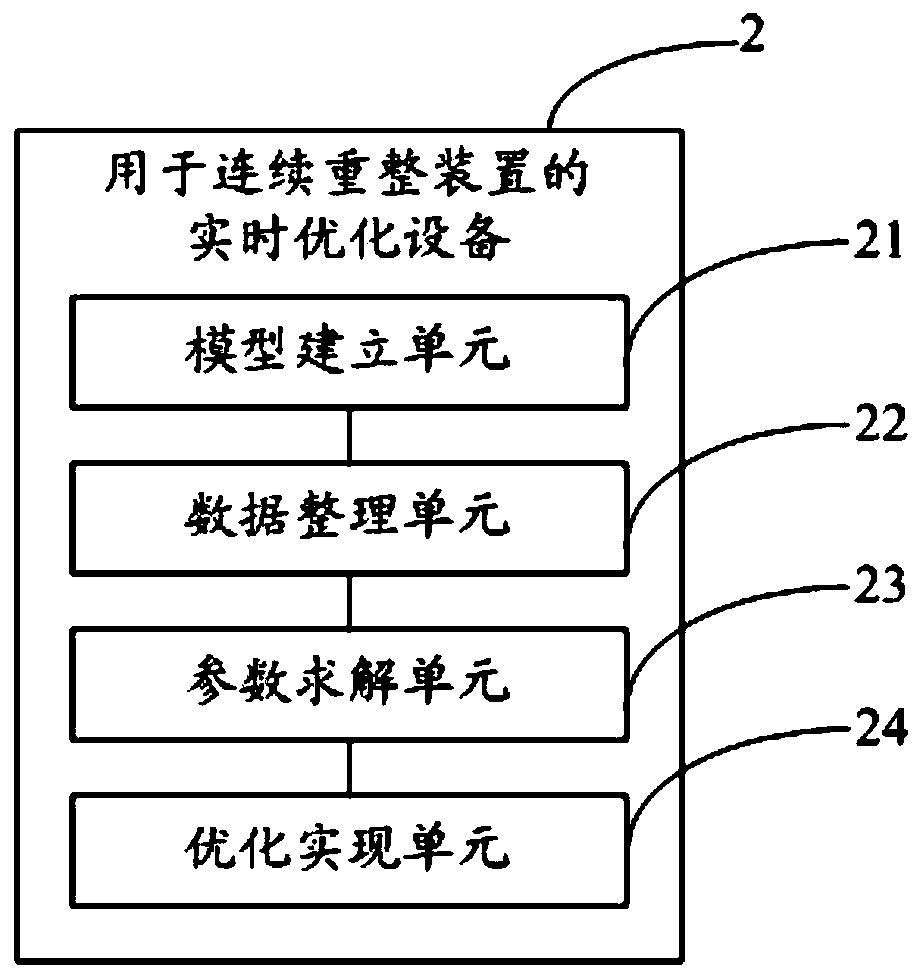

[0119] This embodiment also proposes a real-time optimization device 2 for a continuous reformer, such as figure 2 As shown, the real-time optimization equipment includes:

[0120] The model building unit 21 is used to establish a real-time optimization model of the continuous reformer, and establish an objective optimization function and constraint conditions in the process of solving the objective optimization function in the real-time optimization model;

[0121] The data sorting unit 22 is used to obtain the initial parameters used to import the real-time optimization model of the continuous reforming device from the near-infrared on-line analyzer and the database, process the validity of the initial parameters, and perform data adjustment and processing on the processed data. The operation of model parameter estimation to obtain the data to be imported;

[0122] The parameter solving unit 23 is used to transmit the data to be imported to the real-time optimization model...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com