Storage device, oil refining production device hydrogen distribution prediction method, device and equipment

A technology for distribution forecasting and production equipment, applied in forecasting, measuring equipment, instruments, etc., can solve problems such as many constraints and difficulty in model optimization guidance, to ensure accuracy, improve model calculation accuracy, and optimize extrapolation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

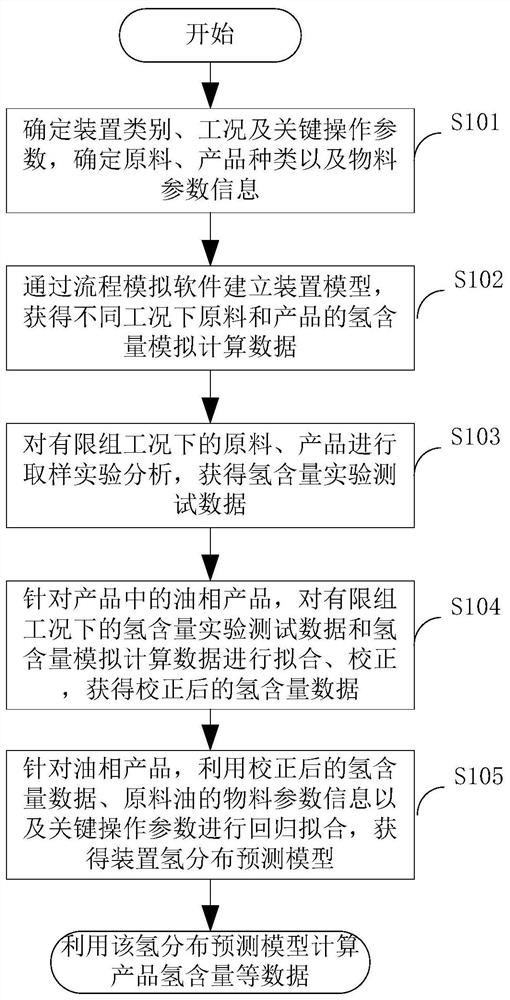

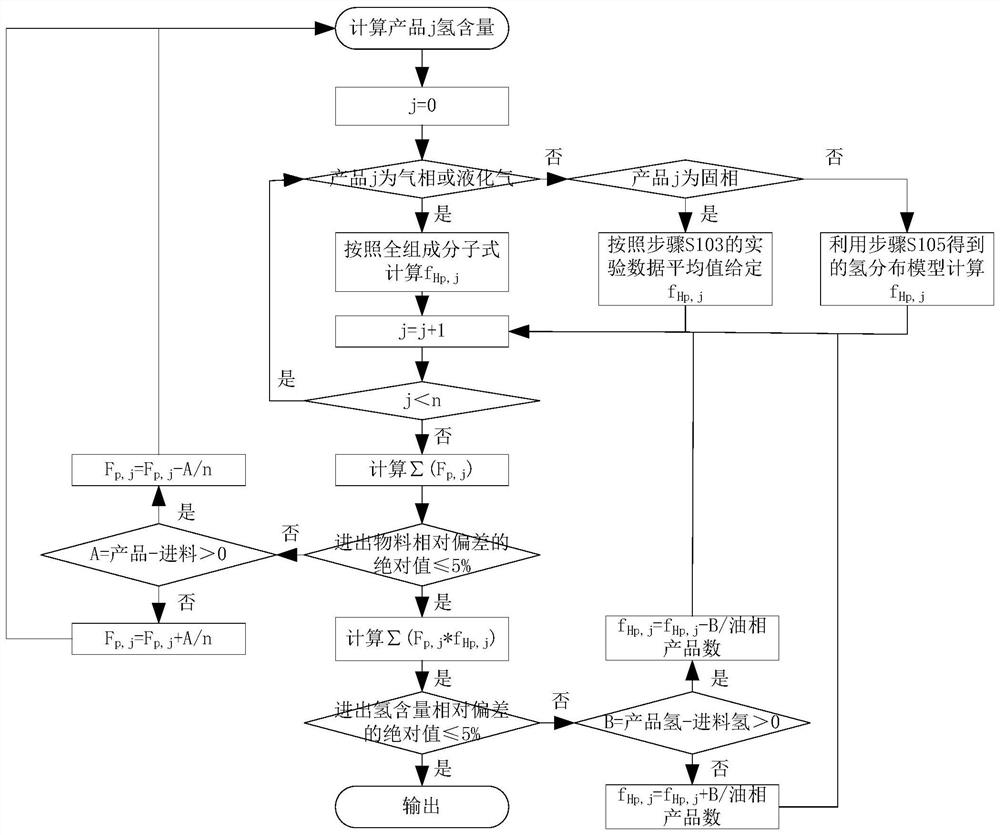

[0046] Such as figure 1 As shown, the method for predicting the distribution of hydrogen in the refinery production unit of Embodiment 1 of the present invention comprises the following steps:

[0047] Step S101, prepare basic information, namely: determine device category, working condition and key operating parameters, determine raw materials, product types and material parameter information.

[0048] Among them, the unit mainly refers to the main unit in the refining process, and the unit category includes atmospheric and vacuum units, continuous reforming units, catalytic cracking units, delayed coking units, solvent deasphalting units, various hydrofining units, various hydrotreating reforming units Quality equipment and various hydrocracking units, etc. Working conditions mainly refer to the corresponding production status of the equipment when the refinery processes the same main types of crude oil within a period of time (for example, within a year).

[0049] The key...

Embodiment 2

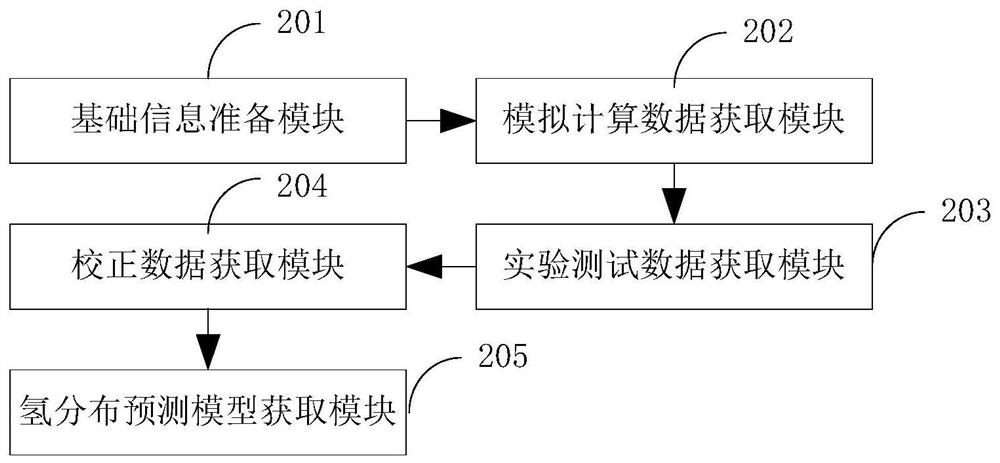

[0141] Such as image 3 As shown, the hydrogen distribution prediction device of the refinery production unit in this embodiment includes: a basic information preparation module 201, a simulation calculation data acquisition module 202, an experimental test data acquisition module 203, a correction data acquisition module 204 and a hydrogen distribution prediction model acquisition module 205. Among them, the basic information preparation module 201 is used to determine the device category, working conditions and key operating parameters, determine the raw materials, product types and material parameter information; the simulation calculation data acquisition module 202 is used to establish device models through process simulation software, and obtain different working conditions Under the simulated calculation data of hydrogen content of raw materials and products; the experimental test data acquisition module 203 is used to carry out sampling experiment analysis on the raw ma...

Embodiment 3

[0143] This embodiment provides a memory, which may be a non-transitory (non-volatile) computer storage medium, and the computer storage medium stores computer-executable instructions, and the computer-executable instructions can execute the oil refining method described in any of the above-mentioned method embodiments. Each step of the hydrogen distribution prediction method of the production device, and achieve the same technical effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com