Cement curing process and system thereof

A cement solidification and process technology, applied in nuclear engineering, radioactive purification and other directions, can solve the problems of low effective utilization rate of container volume and large amount of solid waste, and achieve the effects of low cost, stable hydration reaction and small capacity increase ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

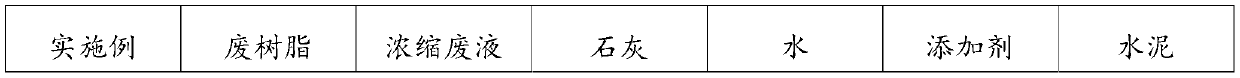

Embodiment 1

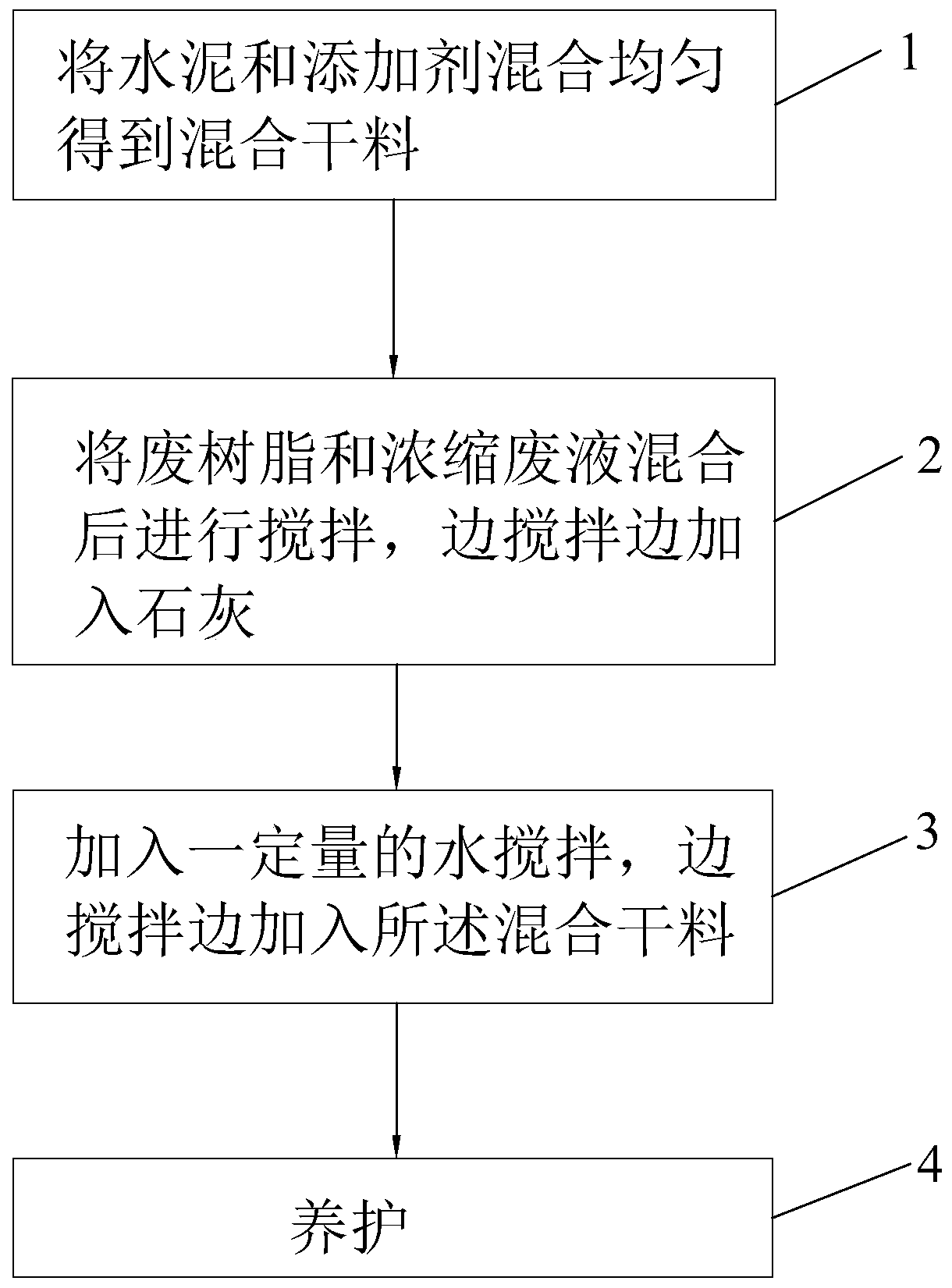

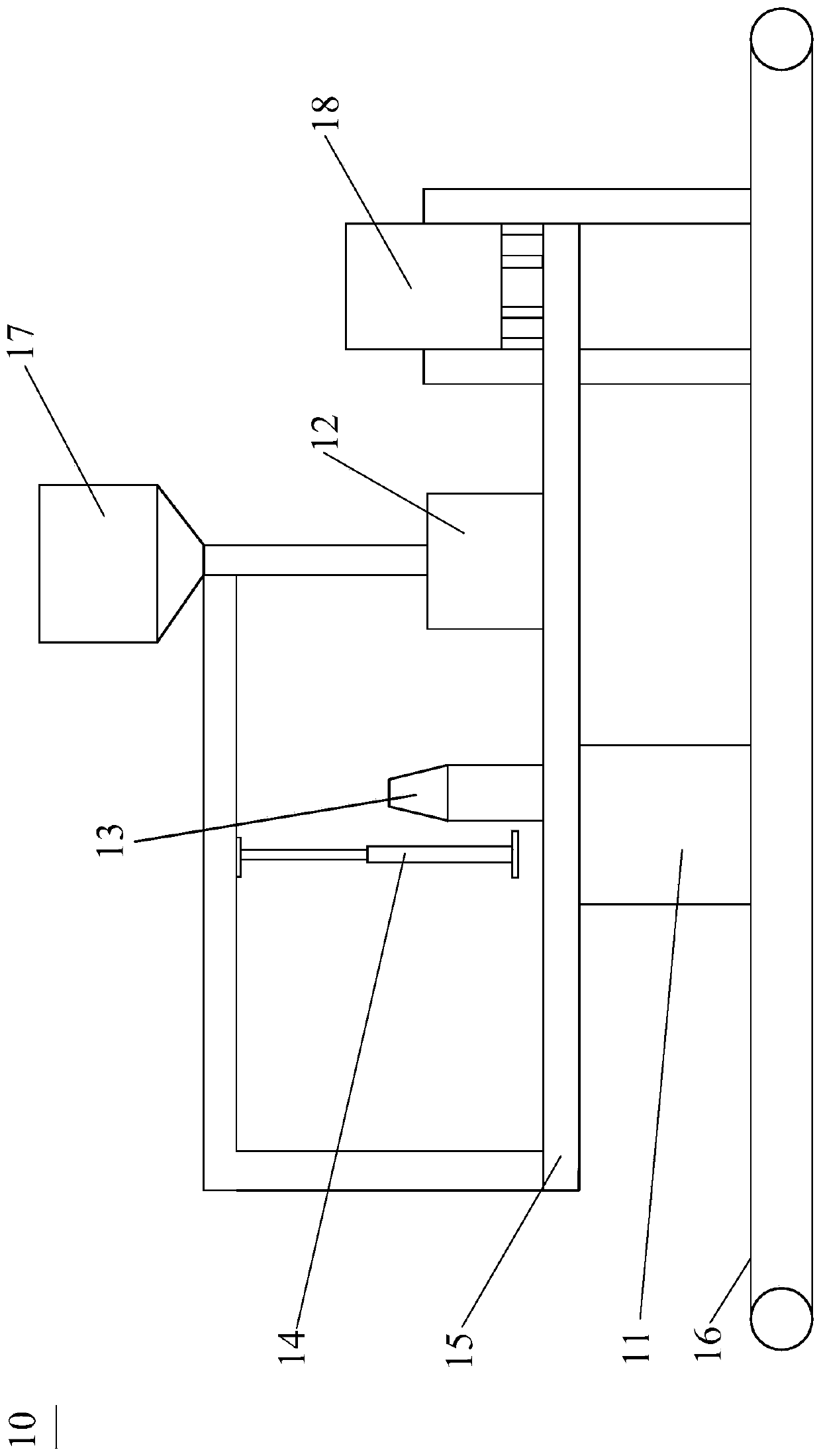

[0030] A kind of cement solidification process, adopts cement solidification system 10 to finish, as figure 2 As shown, the cement curing system 10 includes a metal bucket 11, a wet material filling cover 12, a dry material filling cover 13, a stirring device 14 and a fixed steel platform 15, and a transport roller for transporting the metal bucket is arranged below the fixed steel platform 15 Road 16, the wet material filling cover 12 is used to inject waste resin and concentrated waste liquid into the metal barrel 11, the waste resin is stored by the waste resin tank 17 metering meter, and is added to the metal barrel 11 through the wet material filling cover 12, The dry material filling cover 13 is used to inject cement, additives and lime into the metal bucket 11, and the cement curing system 10 also includes an unsealing cover device 18, which is used for opening and closing the metal bucket lid. The specific cement curing process steps are as follows:

[0031] (1) The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com