Compressor motor, compressor and method for producing compressor motor

A technology for compressors and motors, applied in the manufacture of motor generators, electromechanical devices, and electric components, etc., can solve the problems of poor adhesion, difficult to ensure quality, peeling off insulation film, etc., to prevent short circuits, reliable and effective mechanical properties Effects of connections and electrical connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

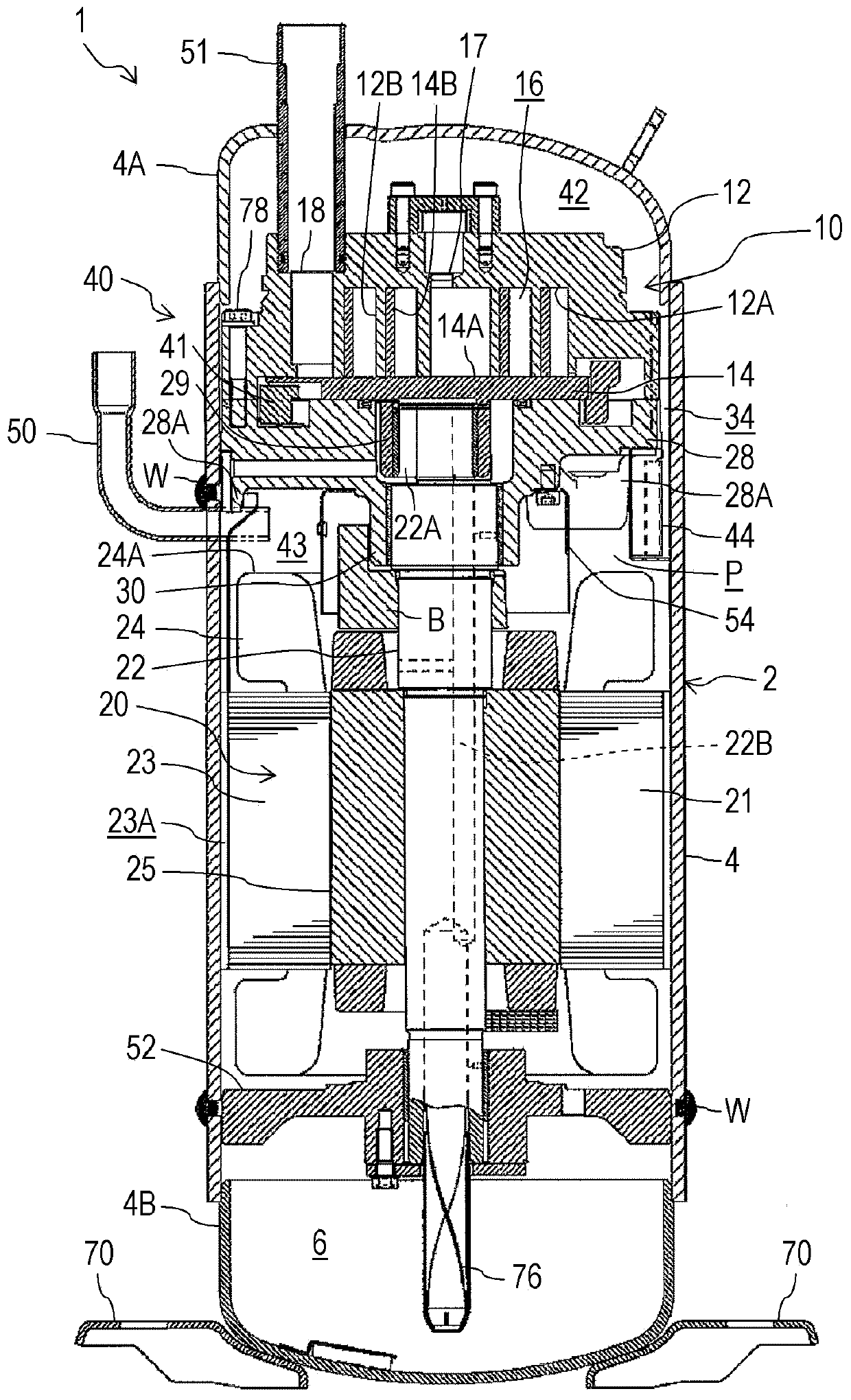

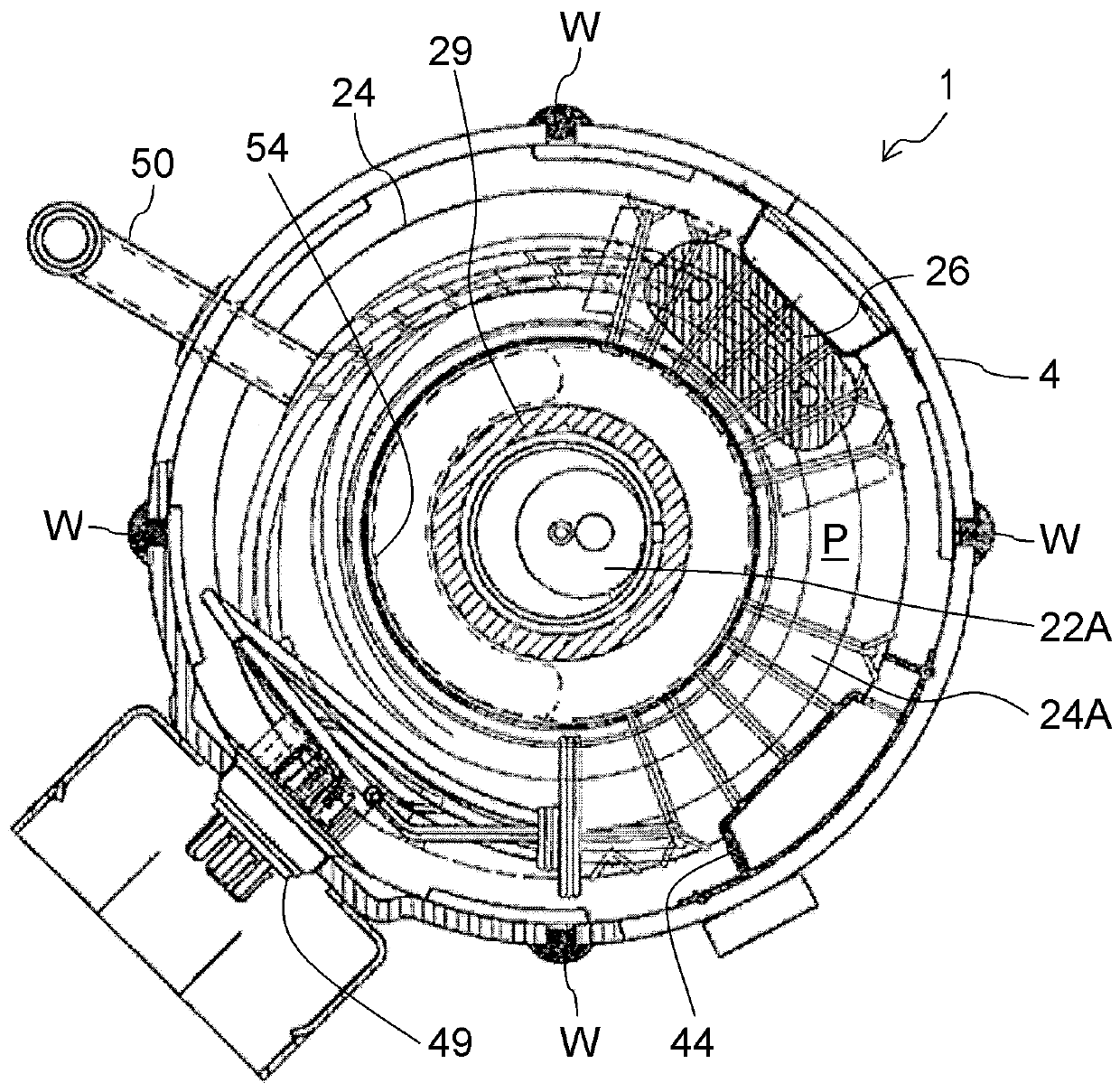

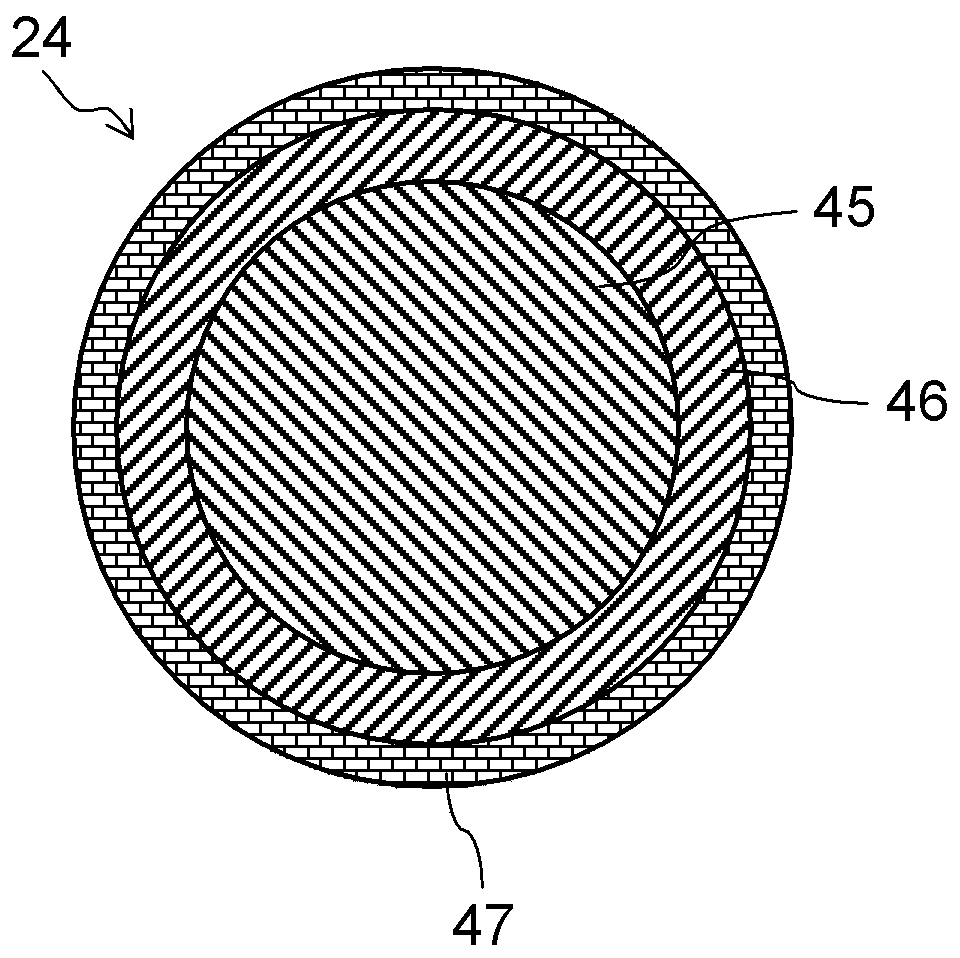

[0032] Hereinafter, embodiments of the present invention will be described in detail. In addition, in the following description, the case where the compressor is a scroll compressor is demonstrated as an example, but the type of compressor is not limited to a scroll compressor.

[0033] figure 1 It is a vertical cross-sectional view of a scroll compressor as a compressor of the present embodiment. figure 2 It is a cross-sectional view of a scroll compressor as a compressor of the present embodiment. As shown in the figure, the scroll compressor 1 is an internal high-pressure type compressor. Such as figure 1 As shown, the scroll compressor 1 includes: a vertical cylindrical airtight container 2 formed of a steel plate; a motor (electric component) 20 accommodated in the inside of the airtight container 2; The rotary shaft 22 of the 20 drives the scroll compression member 10 . Furthermore, figure 1 The vertical scroll compressor 1 shown is figure 1 the top of the figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com