Camera module waterproof structure

A camera module and waterproof structure technology, which is applied in image communication, television, optics, etc., can solve the problems of affecting the imaging performance of the camera module, the edge of the joint is prone to warping, and the internal components are washed away, so as to avoid high-pressure shock Water enters the inside of the camera, improving the waterproof effect and ensuring the service life and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

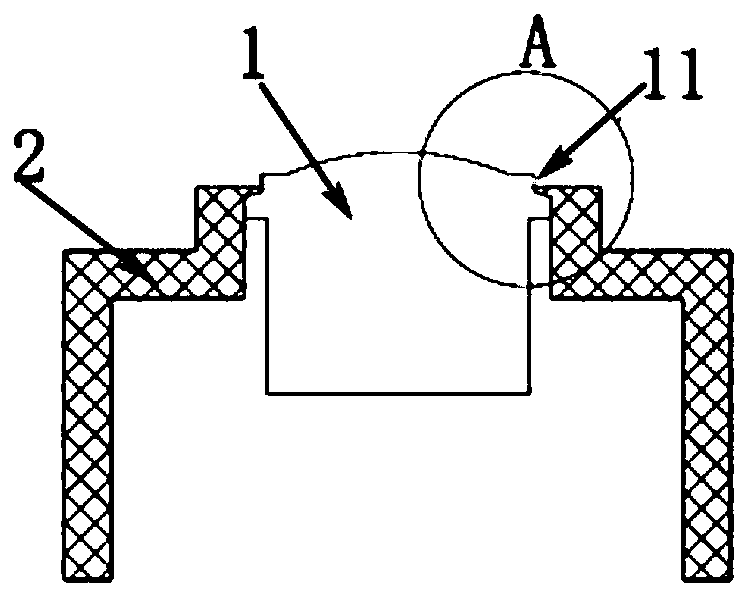

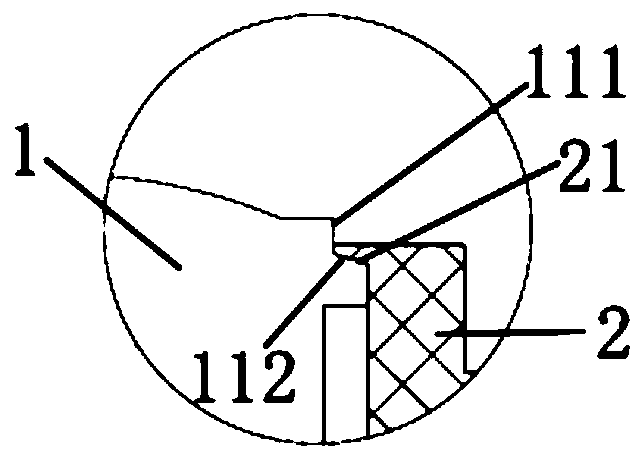

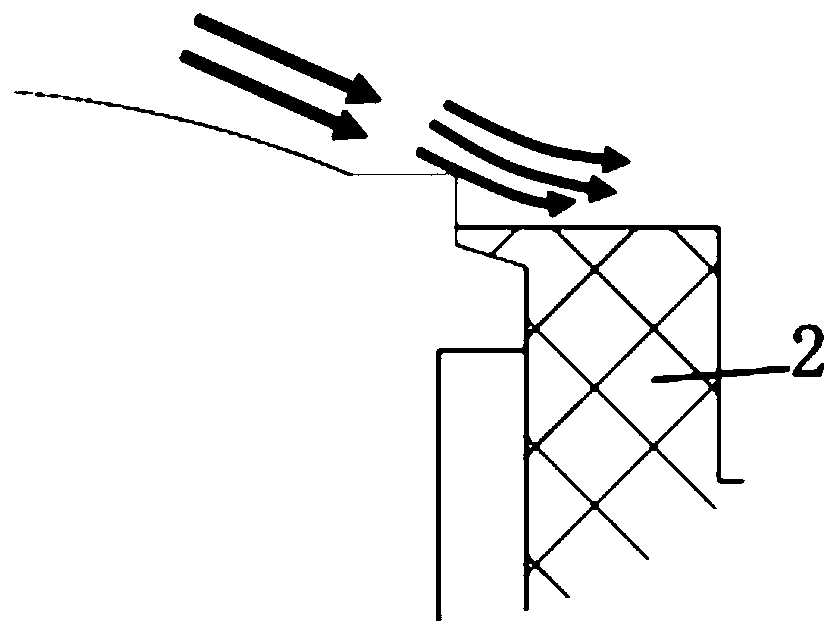

[0046] combine Figure 5-6 As shown, according to the first embodiment of the present invention, the lens 1 of the present invention includes a lens barrel 1a, and a lens group and other optical components are arranged in the lens barrel 1a. The stepped structure 11 of the present invention is arranged on the outer peripheral wall of the lens barrel 1a and connected with the casing 2 . That is, in this embodiment, a stepped structure 11 is provided on the outer peripheral wall of the lens barrel 1a, and the stepped structure 11 includes a first side 111 and a second side 112 connected in sequence, and the second side 112 and the mating surface 21 of the housing 2 Matching connection. In this embodiment, after the mating surface 21 and the second side 112 are mated, the mating surface 21 and the second side 112 can be welded and fixed at the welding point 113 by means of ultrasonic or laser welding, etc., so that the lens 1 and the housing 2 fixed connections.

[0047] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com