A kind of three-dimensional circuit board integrated preparation method and three-dimensional circuit board

A circuit board, three-dimensional technology, applied in three-dimensional rigid printed circuit boards, printed circuit manufacturing, printed circuits, etc., can solve the problems of large copper and chemical materials consumption, environmental pollution, and many processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment provides an integrated preparation method for a three-dimensional circuit board, which is applied to a three-dimensional printing device equipped with an insulating ink extrusion head and a conductive ink extrusion head; the method includes the following steps:

[0050] (1) Constructing a three-dimensional model file according to the three-dimensional structure of the three-dimensional circuit board to be prepared; layering and slicing the three-dimensional model file to generate a printing program;

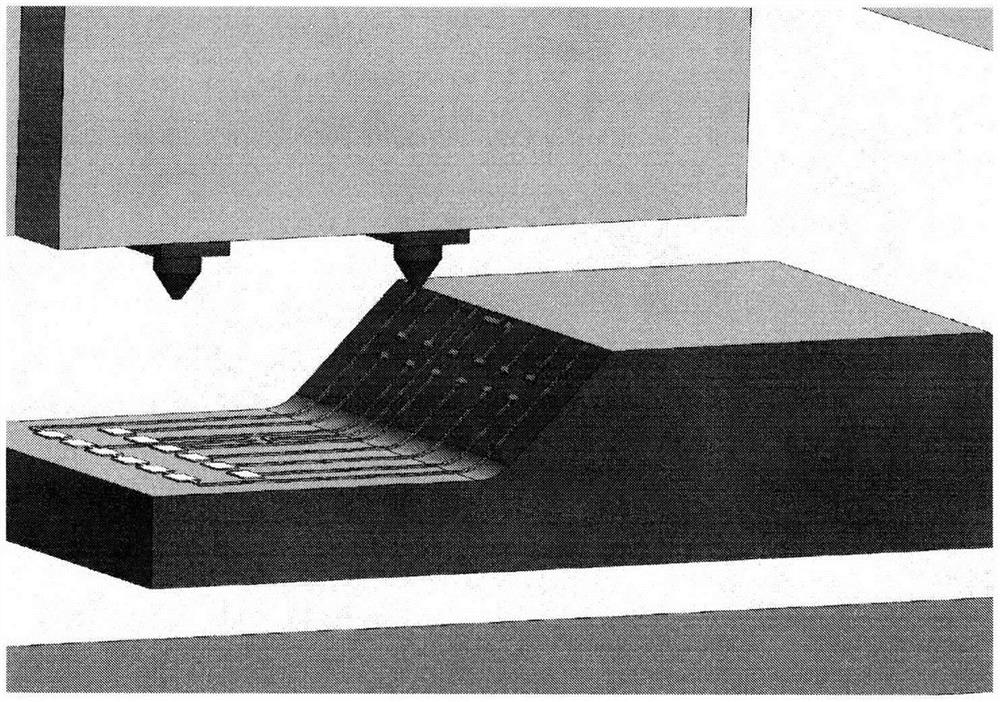

[0051] (2) Under the environment of UV light radiation, according to the printing program, use the insulating ink extrusion head to print UV insulating ink on the surface of the printing platform, and obtain a supporting substrate after curing;

[0052] (3) Under the environment of UV light radiation, according to the printing program, use the insulating ink extrusion head to print UV insulating ink on the surface of the supporting substrate, and obtain an ins...

Embodiment 2

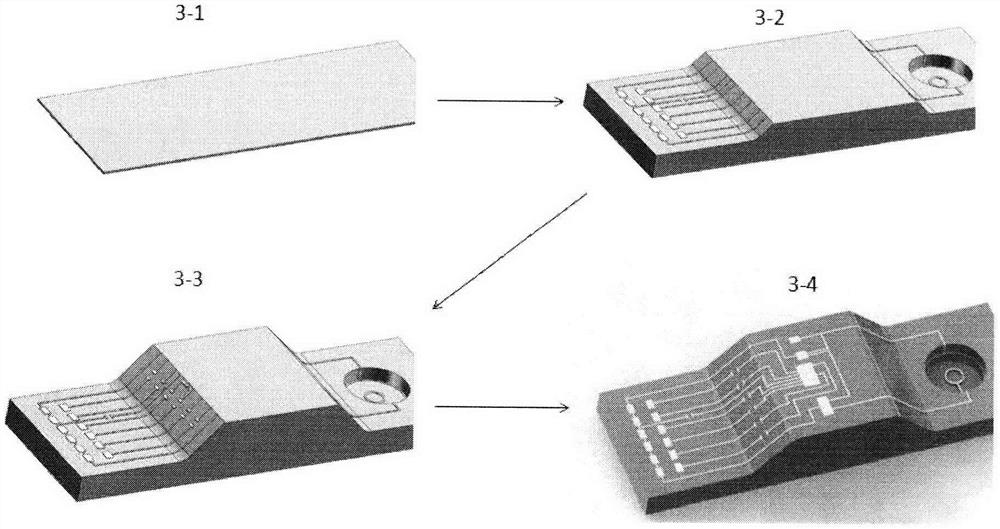

[0085] refer to image 3 , the present embodiment provides a fluid printing method based on dual extrusion heads alternately and cooperatively in a closed UV light radiation environment, so as to realize the integrated fabrication of three-dimensional circuits. Specifically include the following steps.

[0086] (1) According to image 3 Create a 3D model file for the raised circuit board shown in 3-4. Based on the graphic digital slicing technology, the 3D circuit is layered and sliced, the optimized digital slicing algorithm and the nozzle walking path are selected, and the printing program is generated.

[0087] (2) Printing support substrate: Based on the fluid extrusion printing method, UV-curable insulating ink is printed on the surface of the printing platform, and the printed UV insulating ink is gradually cured and formed as a support substrate in a UV light radiation environment. The obtained support substrate is as image 3 as shown in 3-1.

[0088] (3) Print the...

Embodiment 3

[0092] refer to image 3 , the present embodiment provides a fluid printing method based on dual extrusion heads alternately and cooperatively in a closed UV light radiation environment, so as to realize the integrated production of spatial curved surface circuits. Specifically include the following steps.

[0093] (1) According to Figure 4 Create a three-dimensional model file for the space surface circuit shown in 4-4. Based on the graphic digital slicing technology, perform layered slicing processing on the space surface circuit, select the optimized digital slicing algorithm and nozzle walking path, and generate a printing program.

[0094] (2) Printing support substrate: Based on the fluid extrusion printing method, UV-curable insulating ink is printed on the surface of the printing platform, and the printed UV insulating ink is gradually cured and formed as a support substrate in a UV light radiation environment. supporting substrate such as Figure 4 shown in 4-1. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com