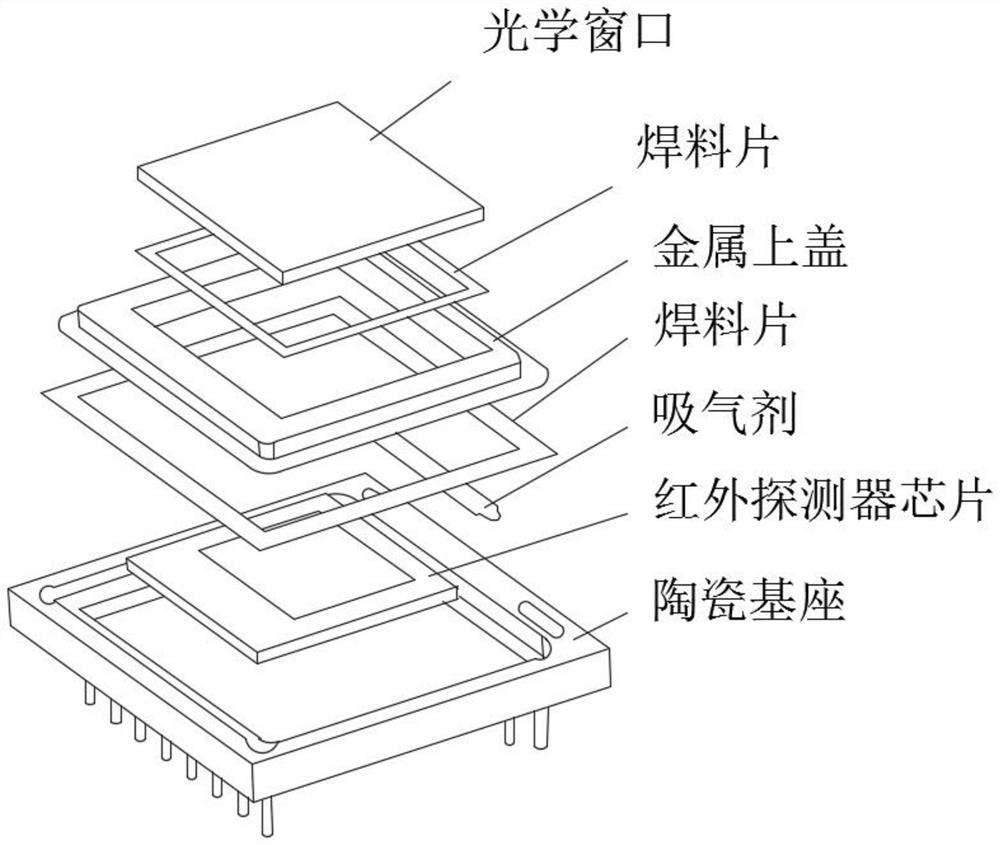

A packaging method for wafer-level infrared detection chips

A technology of infrared detection and packaging method, which is applied in the direction of radiation control devices, semiconductor devices, electrical components, etc. It can solve the problems of too small size of solder sheet, inability to align, deformation, etc., and achieve the effect of high yield rate and high precision of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

[0025] refer to Figure 2-Figure 3 As shown, the present invention discloses a packaging method for a wafer-level infrared detection chip, based on a vacuum reflow soldering machine, the vacuum reflow soldering machine includes an upper cavity and a lower cavity, and the gap between the upper cavity and the lower cavity is Setting a shutter includes the following steps:

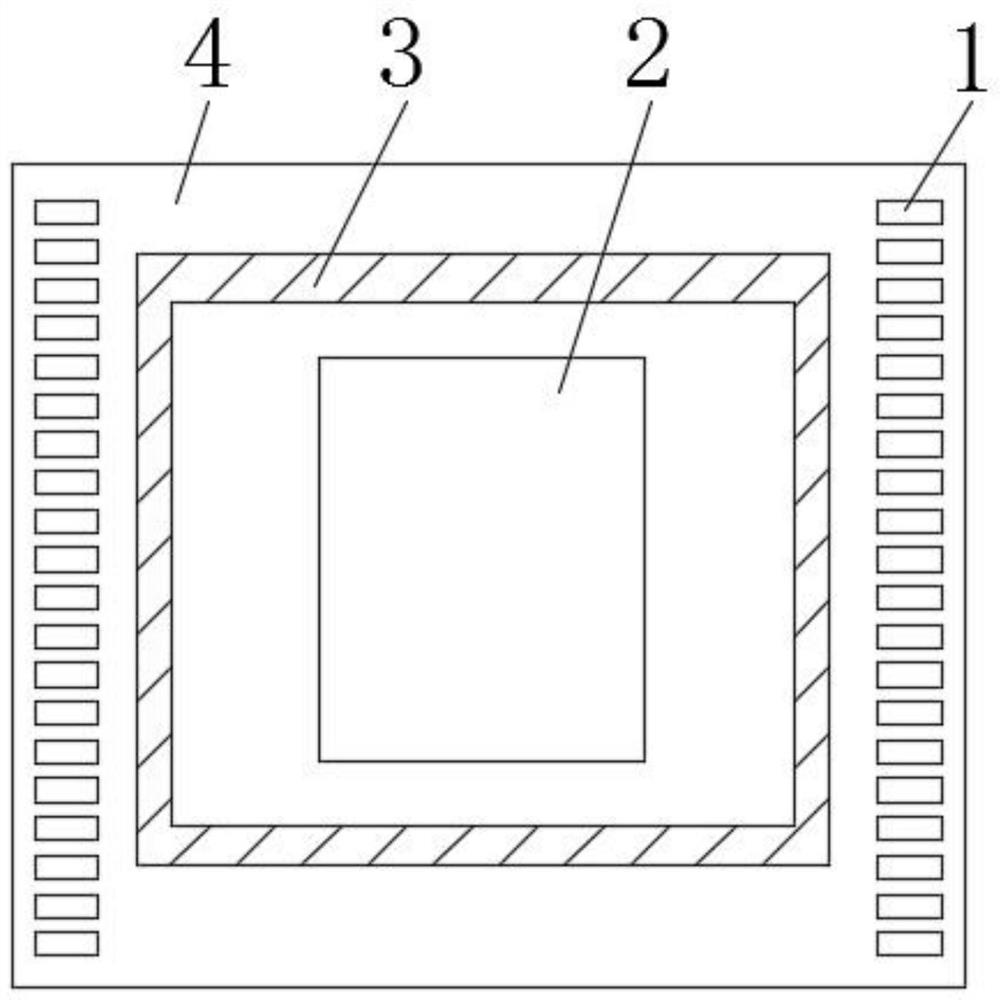

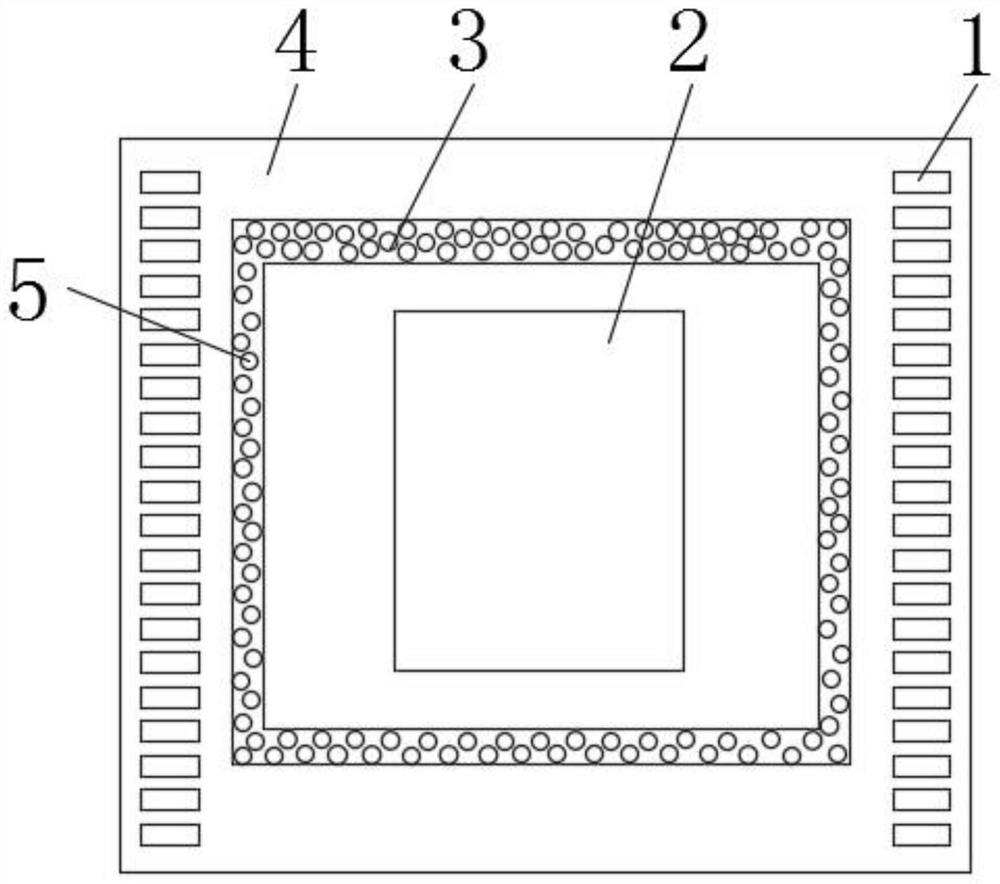

[0026] Step 1, the infrared detection chip 4 includes a photosensitive area 2, a metallized area 3 is arranged around the photosensitive area 2, and a metal layer is arranged on the metallized area 3. Two rows of gold-plated pads 1 are arranged on the infrared detection chip 4, and the metallization area 3 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com