An intelligent control system for jaw crusher and its jaw crusher

An intelligent control system and crusher technology, applied in the field of construction machinery, can solve the problems of easy failure of the toggle plate of the crusher, inability to automatically and accurately adjust the ore discharge opening, and inability to apply a variety of ore working conditions, etc., to achieve intuitive reading. Take, stable and fast protection feedback, to achieve the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

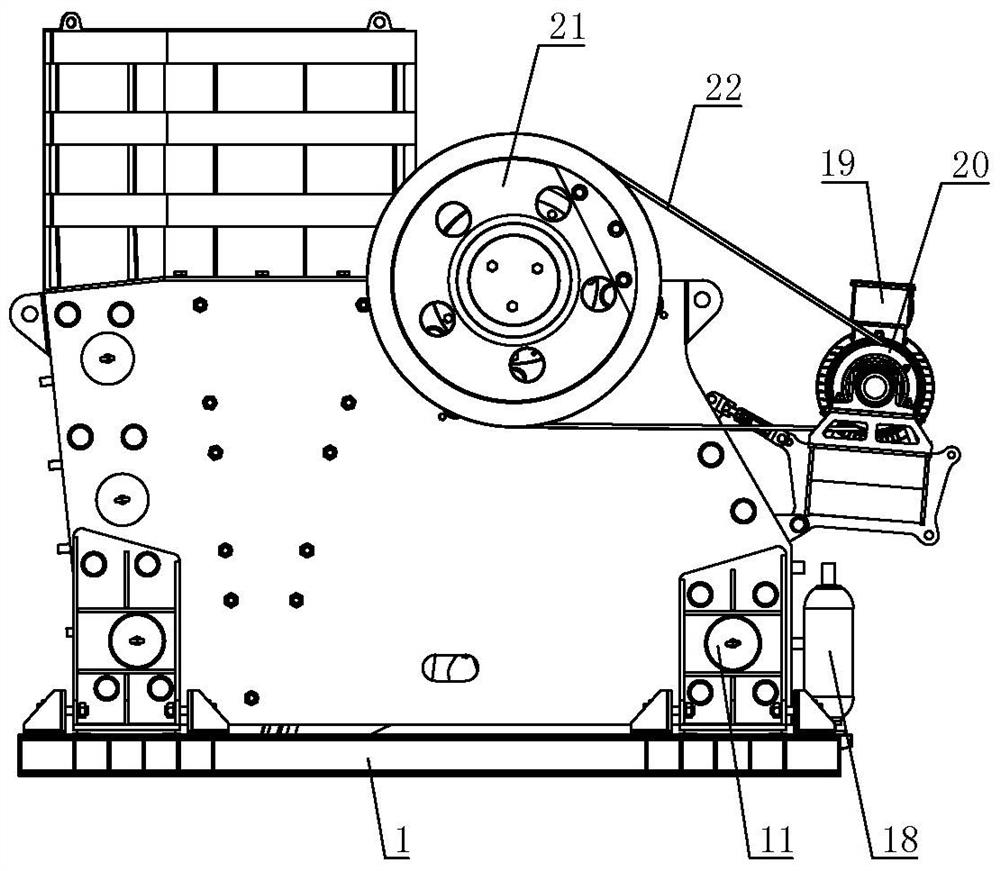

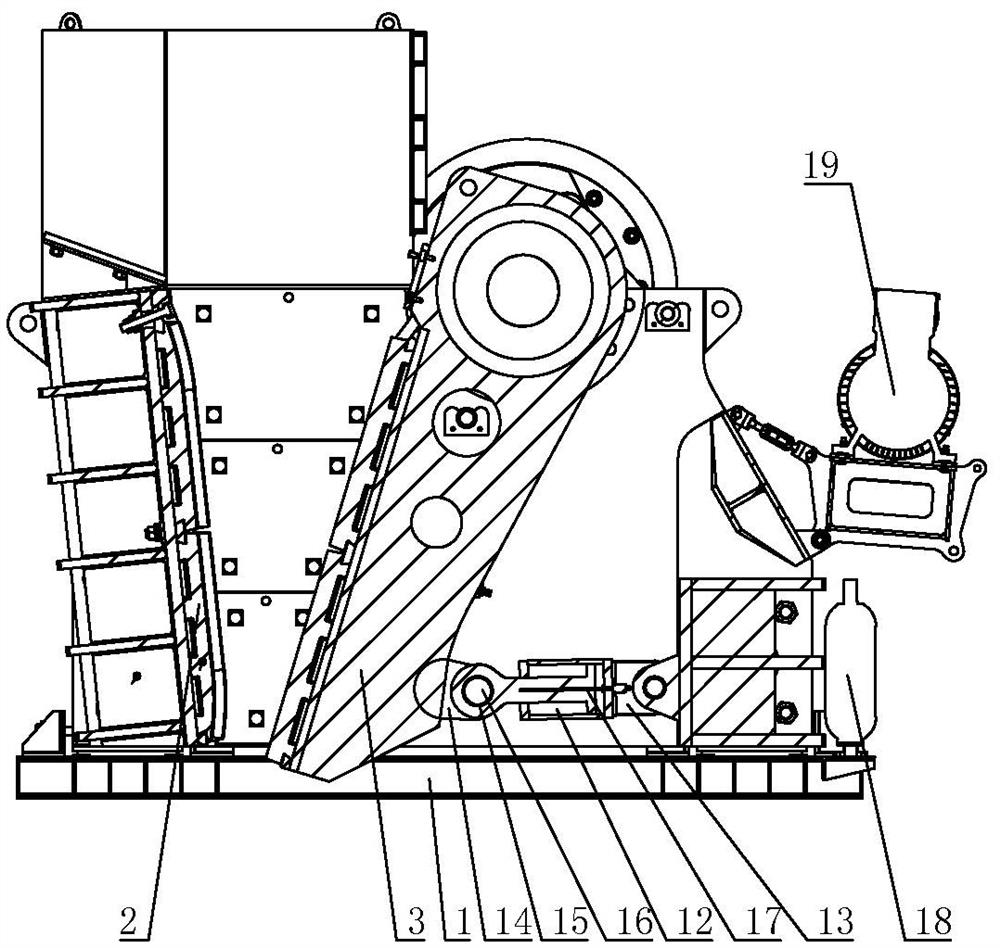

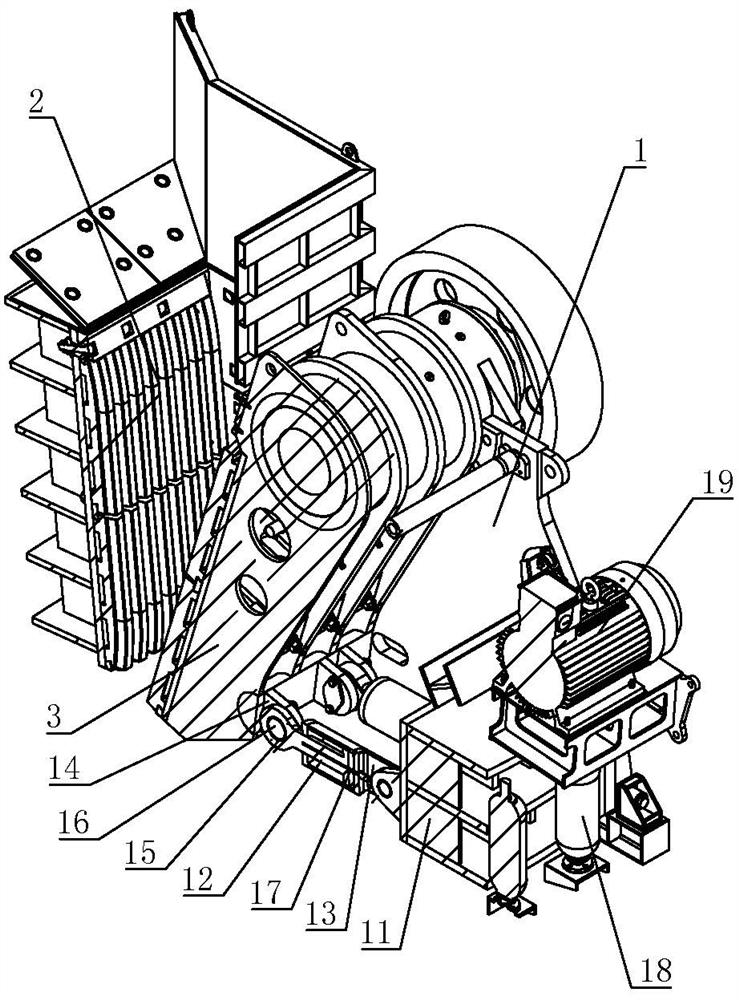

[0018] Depend on Figure 1 to Figure 4 Given, an intelligent control system includes a crusher frame 1, a fixed tooth plate 2 and a movable tooth plate 3, the fixed tooth plate 2 is fixedly installed on the crusher frame 1, and the movable tooth plate 3 is movably installed on the crusher frame. On the frame 1, a crushing chamber is formed between the fixed tooth plate 2 and the movable jaw tooth plate 3, and the lower end of the crushing chamber is the ore discharge port 4. The intelligent control system also includes a movable jaw stroke for driving the movable jaw tooth plate to form a stroke The adjusting device and the four-in-one intelligent control system connected with the movable jaw tooth plate 3, the four-in-one intelligent control system includes a movable jaw stroke compensation device and an automatic adjustment device for the size of the ore discharge port 4, and the movable jaw stroke compensation device can compensate the movable jaw stroke The movement displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com