Box culvert construction method based on movable inner formwork jumbo

A construction method and technology for box culverts, which are applied in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of high construction cost, long time, and many reinforcement supports, and achieve the effect of fast construction progress and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

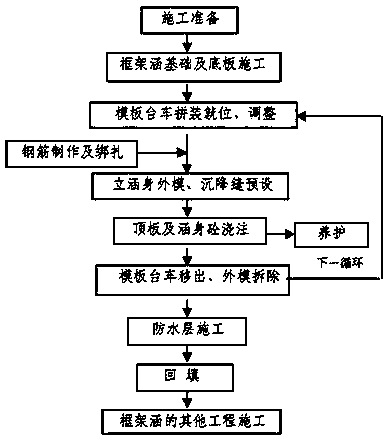

[0036] The box culvert construction method of the present embodiment is suitable for a frame box with a tight construction period and a length greater than 50 linear meters. The horizontal meter of the culvert in this embodiment is the length above the cross section. The design idea of this embodiment is: assemble the inner formwork into a 6m long, 6m wide, and 4m high inner formwork trolley, and by laying the trolley running track, the inner mold can be assembled at one time and moved as a whole, which speeds up the construction schedule.

[0037] The large box culvert is constructed with a mobile internal formwork trolley. From the installation of steel bars to the removal of the formwork, the internal formwork trolley can complete a construction section every 4 days, while the combined steel formwork takes 7 to 10 days, and the casting cycle is short. The construction progress is greatly accelerated, and the effect of saving the construction period is obvious.

[0038] P...

Embodiment 2

[0055] On the basis of the solution disclosed in embodiment 1, this embodiment discloses the following technical solutions.

[0056] The production of steel bars should be reasonably matched according to the length of blanking materials, and the length of raw materials (especially threaded steel bars) should be selected so as to reduce or optimize the overlapping and welding conditions during construction. In special cases, the steel bars are indeed exposed for a long time, and the surface of the steel bar skeleton is sprayed with cement slurry for protection.

[0057] Concrete is an important factor in the construction quality of culverts. The slump of concrete should be controlled at 85mm. During the vibration process of concrete, fast insertion and slow removal should be adopted to eliminate air bubbles in the concrete, but the time should not be too long to prevent excessive vibration. vibration. It is advisable for the thickness of the concrete to enter the mold to be 30...

Embodiment 3

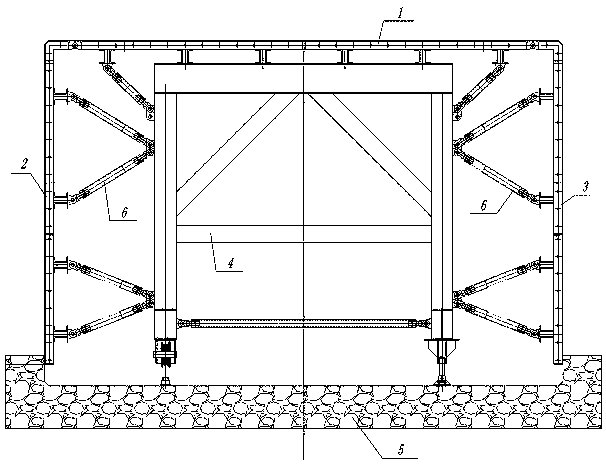

[0063] On the basis of the solutions disclosed in Embodiment 1 and Embodiment 2, this embodiment discloses the structure of the mobile inner mold trolley.

[0064] Such as Figure 2-Figure 4 As shown, the mobile inner mold trolley includes: a template, an inner support frame 4, and a part of the inner support frame 4 is located in the inner cavity of the template; Board 3, the top of the first side board 2 and the second side board 3 have a horizontal part extending to the direction of the top board 1, the horizontal part is parallel to the top board 1; the longitudinal section of the first side board 2 is "" shape, The second side plate 3 and the first side plate 2 are symmetrical along the height direction of the box culvert; the horizontal parts of the first side plate 2 and the second side plate 3 are all hinged with the side wall of the top plate 1, and the first side plate 2 and the second side plate The plate 3 can rotate towards the inner support frame 4 around the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com