Device and method for improving thickness of coal seam exploited by coalcutter by using abrasive jet

A technology of abrasive jet flow and coal seam thickness, which is applied in the field of high coal seam coal rock or complex coal seam, can solve the problems of restricting the rapid mining of coal rock, low flexibility of coal seam height adjustment, difficult mining, etc., and achieves important social and economic significance. Benefits, promotion of mechanized mining, and the effect of high mining coal and rock height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

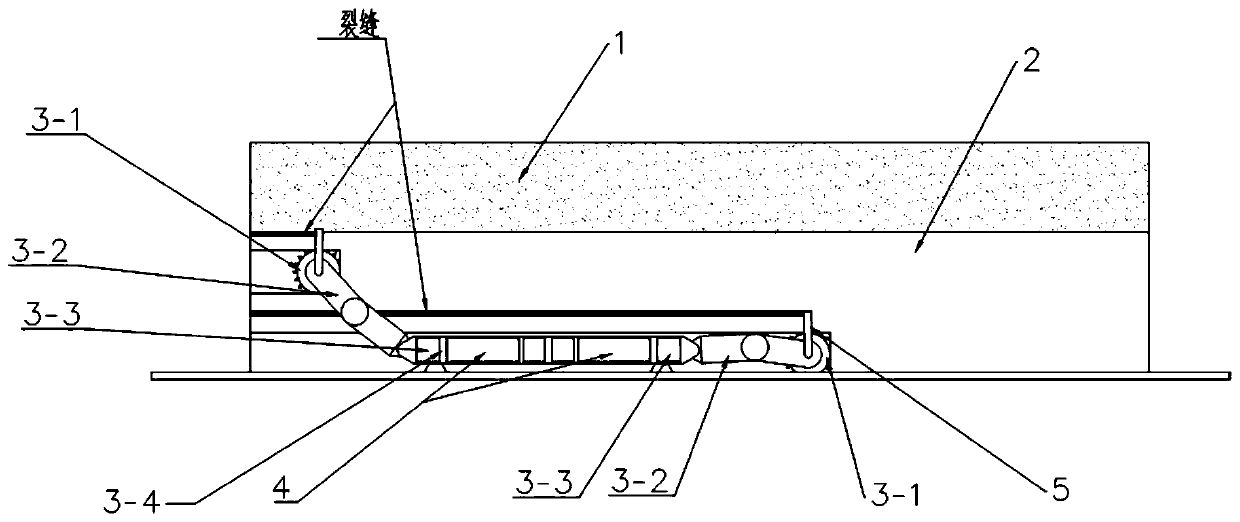

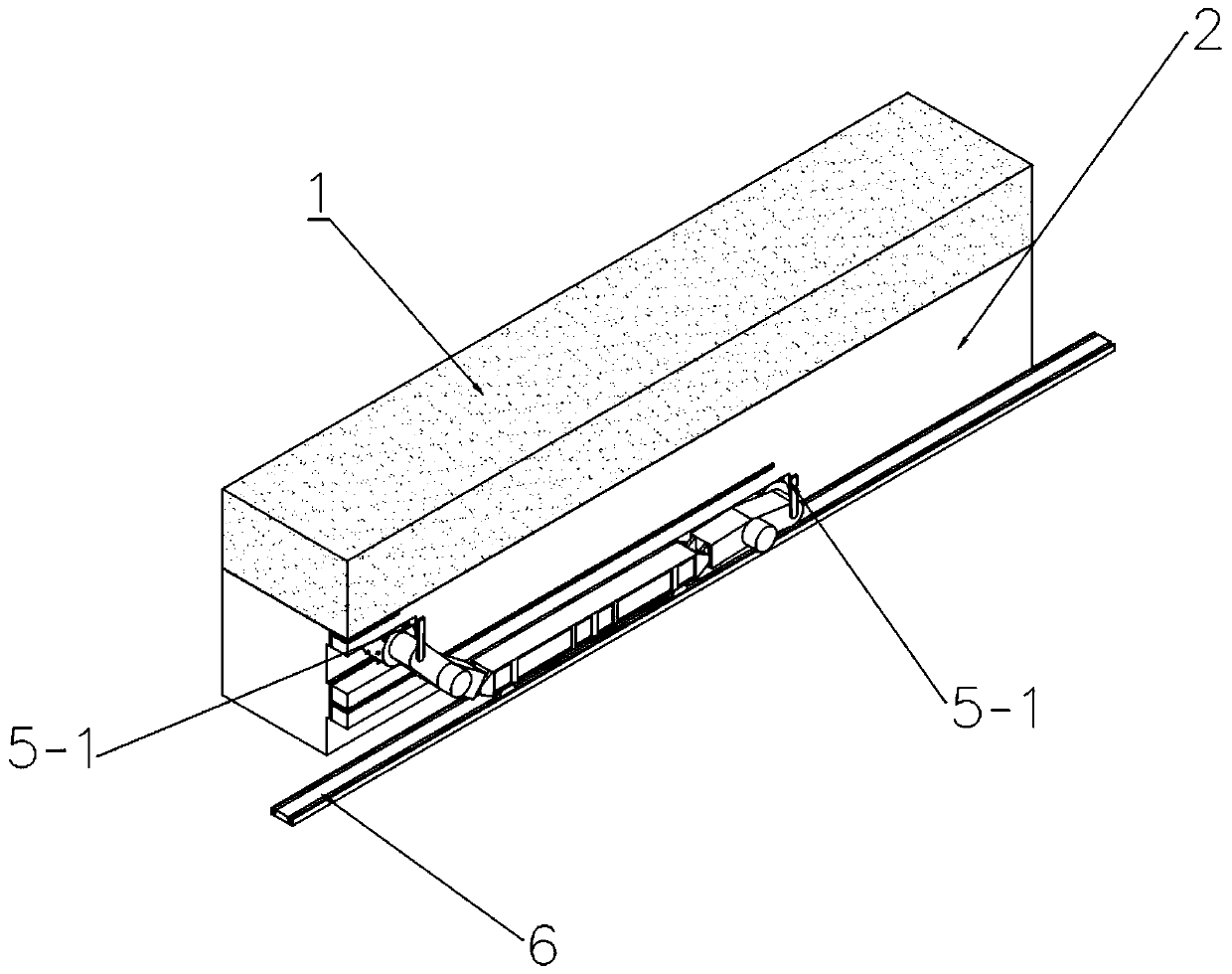

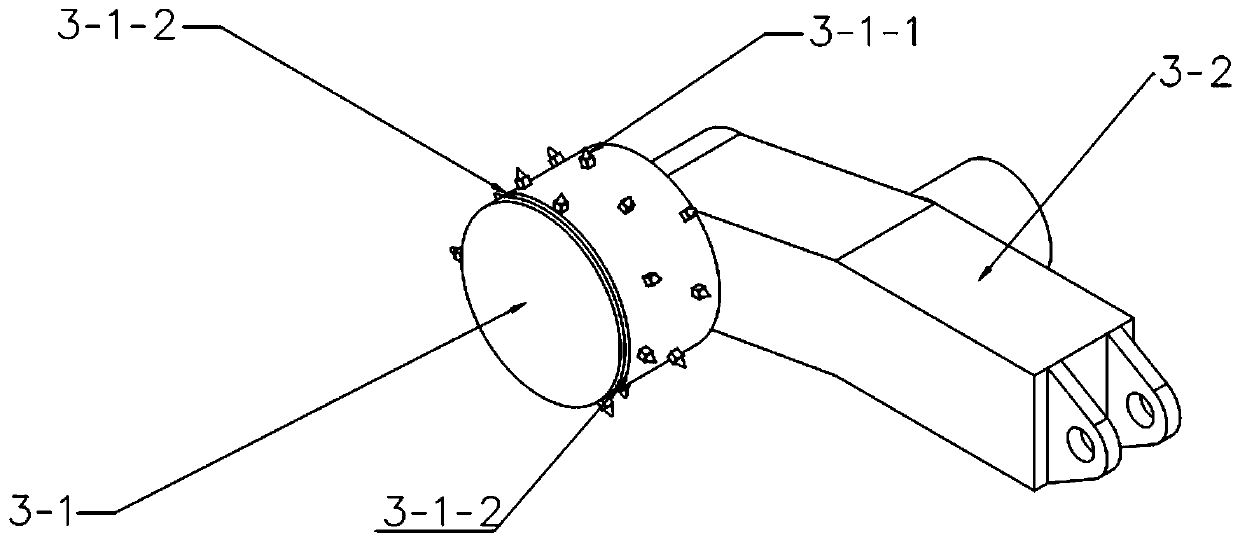

[0028] like Figure 1-3 As shown, a device for improving the thickness of coal seams mined by a shearer by using abrasive jets includes a scraper 6 and a double-drum shearer 3 installed on the scraper 6. The scraper 6 is a track, and the double The drum shearer 3 moves horizontally on the track. The double drum shearer 3 includes a drum 3-1, a cutting arm 3-2, a height-adjusting oil cylinder 3-3 and a body 3-4. The body 3 Abrasive jet generator 4 is loaded on -4, a cutting arm 3-2 is connected to both sides of the fuselage 3-4, and a height-adjusting oil cylinder 3-3 is installed on both sides of the fuselage 3-4. 3-3 is connected with the cutting arm 3-2 on the corresponding side, and one side of the end of the cutting arm 3-2 is provided with a drum 3-1, and the cylindrical outer wall of the drum 3-1 is provided with a number of mechanical cutters. Tooth 3-1-1, two...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap