Degassing pans for gas turbine lube oil tanks

A technology for lubricating oil tanks and gas turbines, which is applied in the direction of engine lubrication, turbine/propulsion device lubrication, and lubricating parts. It can solve the problems of reducing the gas content of lubricating oil, complex structure, and high manufacturing cost, and achieve air reduction and greater freedom. Surface area, the effect of reducing the impact potential energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

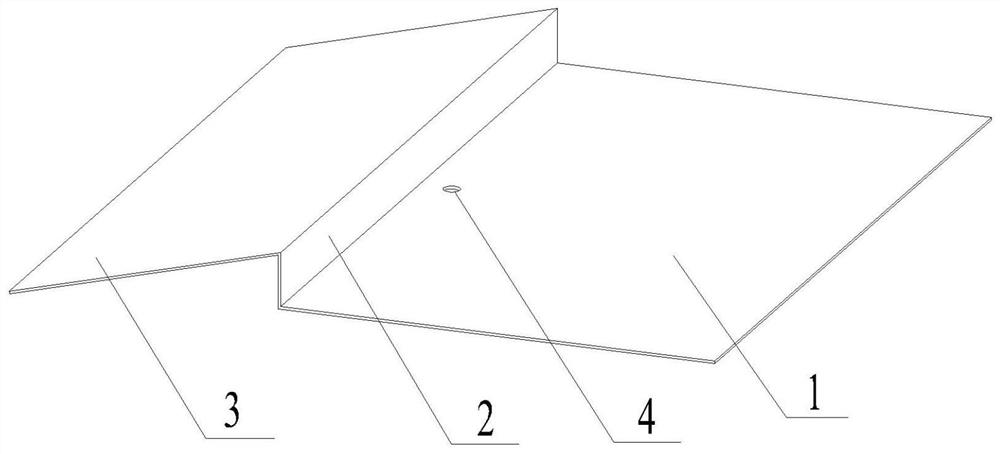

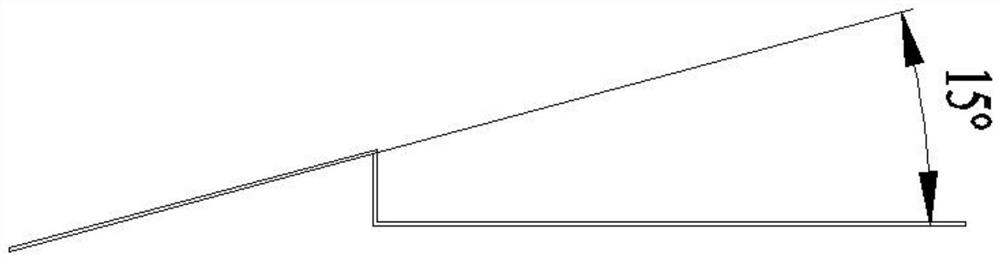

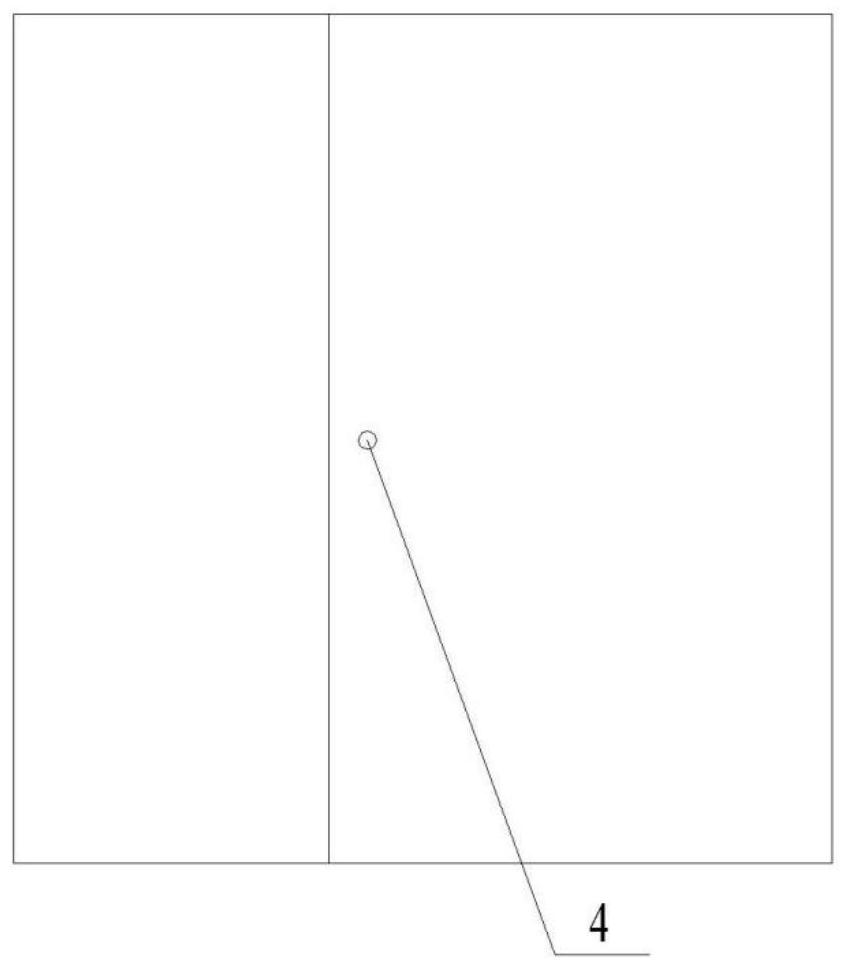

[0036] The degassing tray provided in this embodiment includes: the degassing tray body, which is horizontally arranged on the inner wall of the fuel tank and is lower than the oil return port of the system, and is used to accept the oil return of the system; One side of the mouth, the bottom of the step is connected to the body of the degassing plate; the slope, the top of the slope is connected to the top of the step, and the end of the slope goes deep into the interior of the fuel tank; the oil drain hole is opened on the body of the degassing plate, and the diameter of the oil drain hole is 25mm. When this embodiment is actually used in a certain gas turbine lubricating oil tank, the amount of lubricating oil required by the gas turbine is 1800L / min, and the total volume of the lubricating oil tank is 13.7m 3 , the oil storage area of the fuel tank is 15m 2 , the actual height inside the fuel tank is 0.91m. There are two degassing discs in the fuel tank. The flow rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com