Three-dimensional infrared radiation heating system

An infrared radiation, three-dimensional technology, applied in the field of three-dimensional infrared radiation heating system, can solve the problems of uneven temperature, reduce indoor air heating effect, increase infrared radiation reflectivity, etc., to achieve enhanced heating effect and stable structure The effect of improving the performance and uniformity of infrared radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

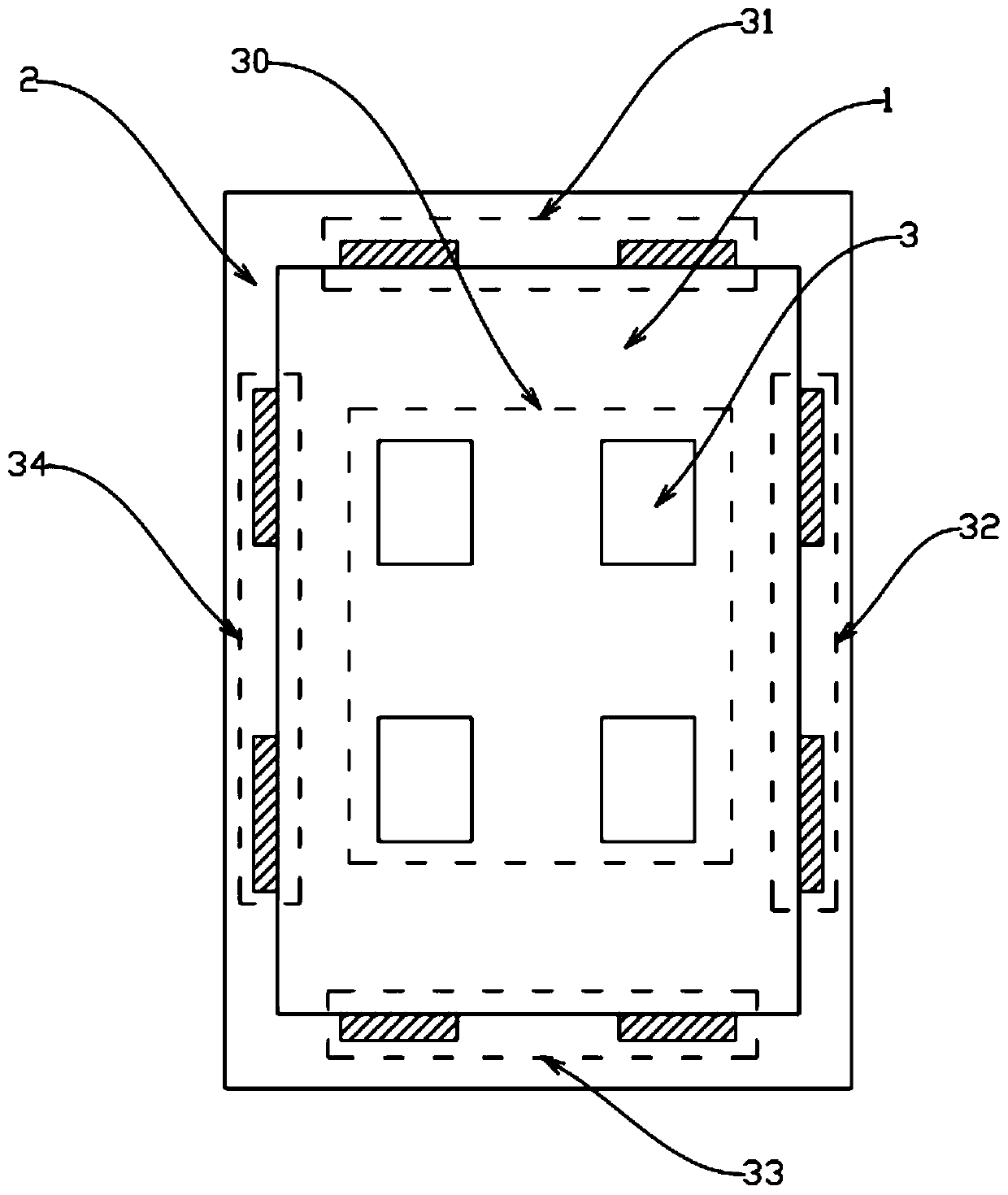

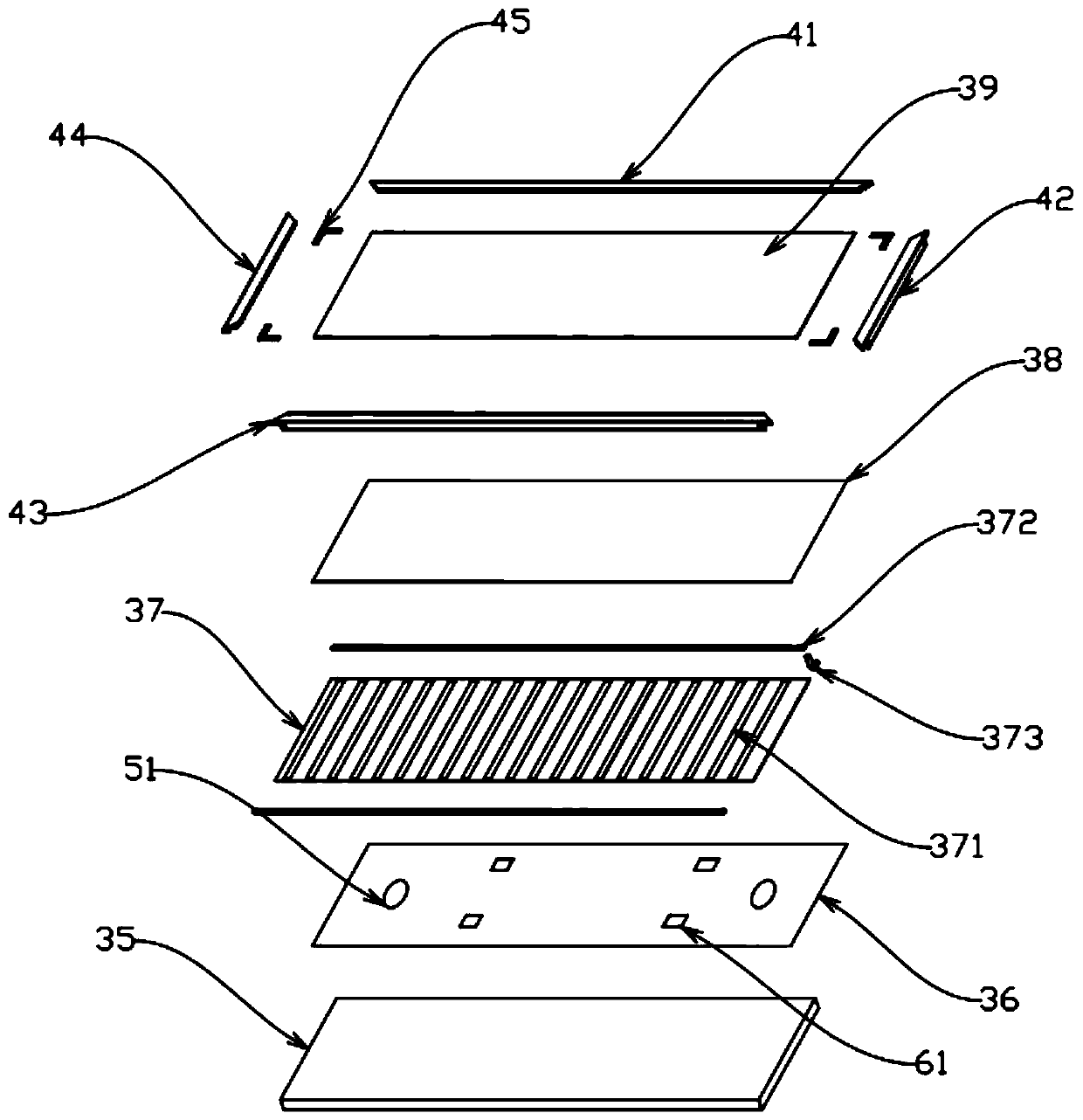

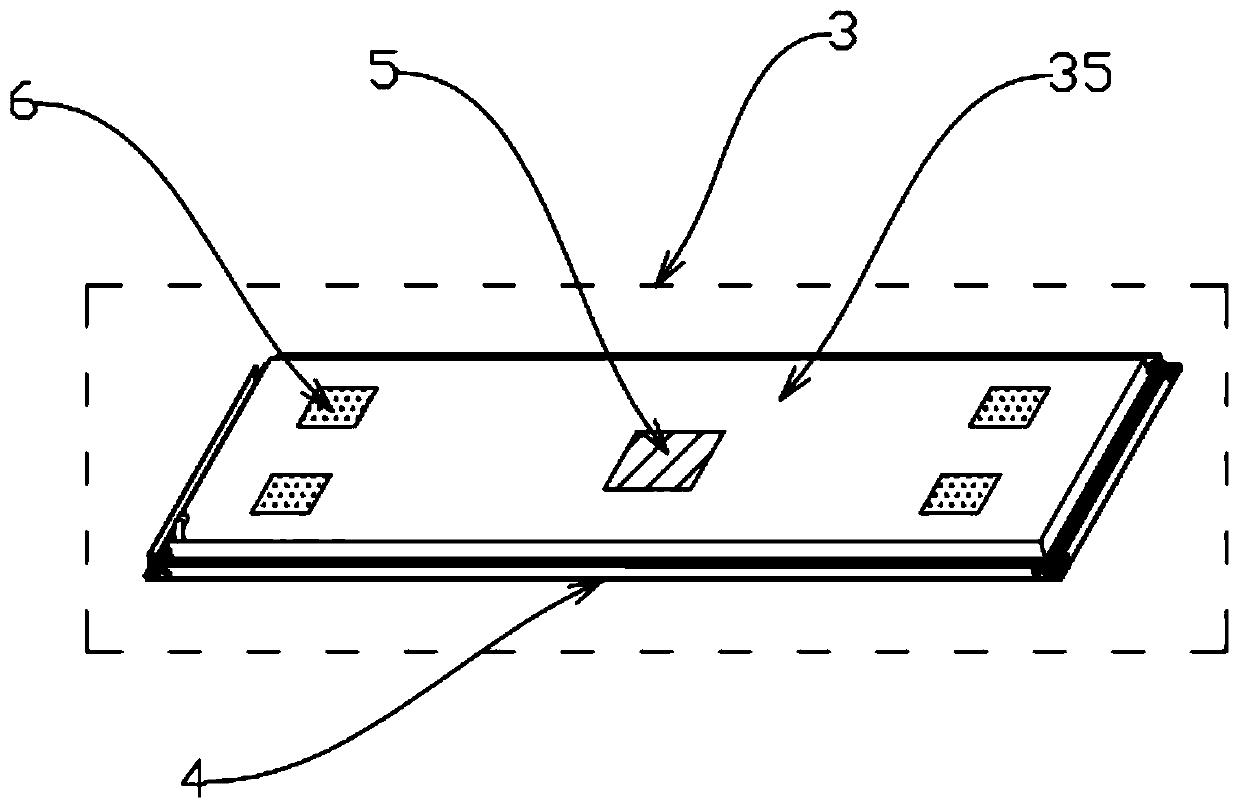

[0048] Such as Figure 1 to 3 As shown, a three-dimensional infrared radiation heating system includes a plurality of ceiling module units 3 arranged on a ceiling 1 and a wall 2 respectively, and the ceiling 1 is equipped with a first combination of multiple ceiling module units 3 The heating module 30, the proportion of the area S1 of the first heating module 30 on the ceiling 1> 50%; a second heating module 31, a third heating module 32, a fourth heating module 33, and a fifth heating module 34 formed by a combination of multiple ceiling module units 3 are respectively installed on the wall 2 adjacent to the ceiling 1, the The second heating module 31, the third heating module 32, the fourth heating module 33, and the fifth heating module 34 occupy an area S2> corresponding to the wall 2 30%; the first heating module 30, the second heating module 31, the third heating module 32, the fourth heating module 33, and the fifth heating module 34 are all connected to the controller 5...

Embodiment 2

[0059] Similar to Example 1, the difference is only in the structure of the panel frame, such as Figure 4 with Figure 5 As shown, the panel frame 4 is welded by a number of connecting pieces 46. One edge of each connecting piece 46 protrudes upward to form a card 404 for connecting the keel, and the other edge is provided with an overlap joint for placing a heat insulation board 35. A groove 406 is provided between the two edges of the connecting member; the connecting member 46 and the heat insulation board 35 are firmly connected by a spring sheet 7, and one end of the spring sheet 7 is connected to the overlap plate 405 A accommodating space for the heat insulation board 35 is formed between the two ends, and the V-shaped structure at the other end is clamped into the groove 406 to clamp the heat insulation board 35 between the lap board 405 and the spring sheet 7. The V-shaped structure is picked out, and then the ceiling module unit 3 is removed from the panel frame 4.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com