A remote temperature and humidity test method for environmental test equipment calibration

A technology of environmental testing and remote testing, applied in the direction of measuring devices, instruments, etc., can solve the problems of inability to provide temperature and humidity out-of-range alarms, inability to use real-time monitoring of ambient temperature, and lack of real-time signal transmission modules, etc., to achieve remote real-time observation of data , Reduce human judgment errors, reduce the effect of requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

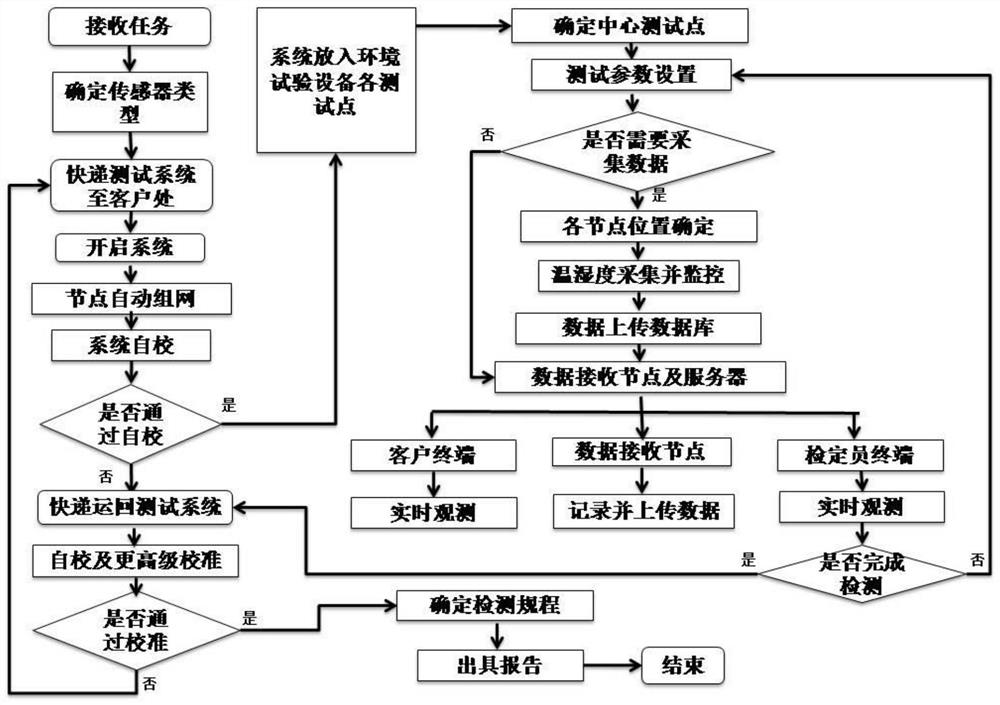

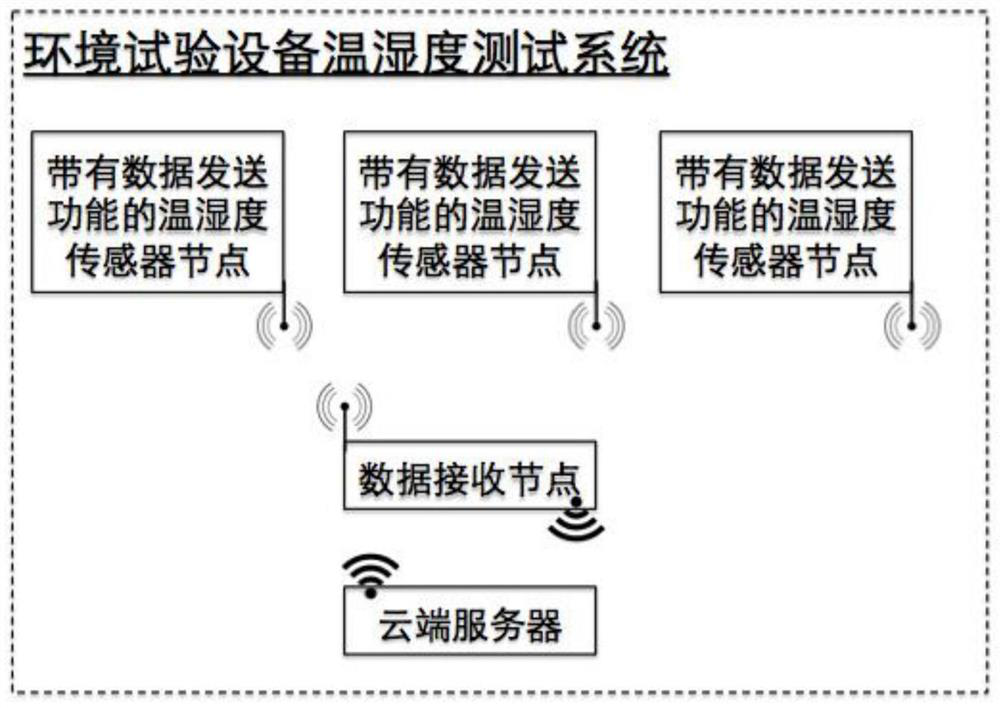

[0043] The present invention will be further described in detail in conjunction with the following specific embodiments and accompanying drawings. The process, conditions, experimental methods, etc. for implementing the present invention are common knowledge and common knowledge in the art except for the content specifically mentioned below.

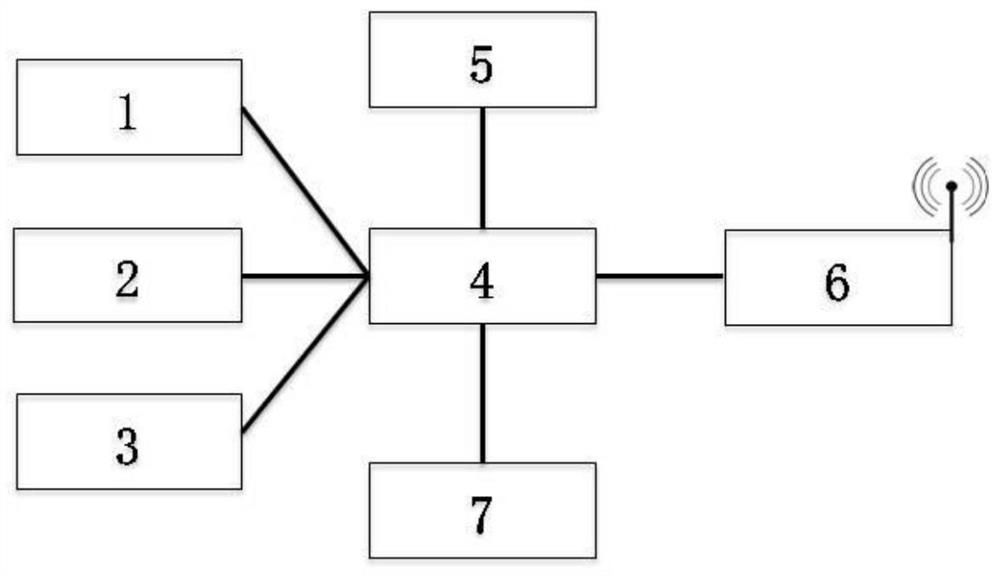

[0044] Such as Figure 1-4 As shown, 1-thermocouple interface, 2-thermal resistance interface, 3-temperature and humidity sensor interface, 4-control module, 5-first power supply and charging module, 6-signal transceiver and positioning module, 7-temperature and humidity self-calibration Module, 10-first signal transceiver and positioning module, 11-second signal transceiver and positioning module, 12-temperature and humidity probe module, 13-memory module, 14-control module, 15-second power supply and charging module, 16- Wireless network transceiver module, 17-indicating screen and voice module, 18-temperature and humidity self-calibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com