Test method, system and device for No. 3 seal filter of main pump

A test method and filter technology, which are applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of inability to effectively verify the continuity of injection water, poor water flow through the No. 3 injection filter, and high risk of personnel contamination, and improve the The effect of personnel maintenance technology and equipment maintenance quality, function integrity, and equipment reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

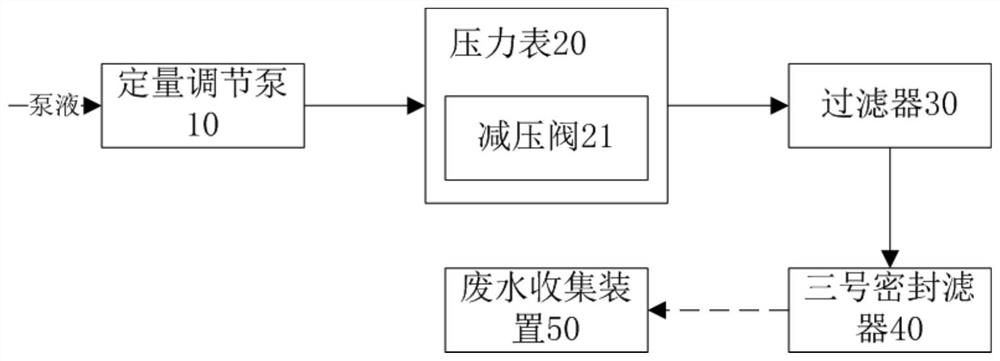

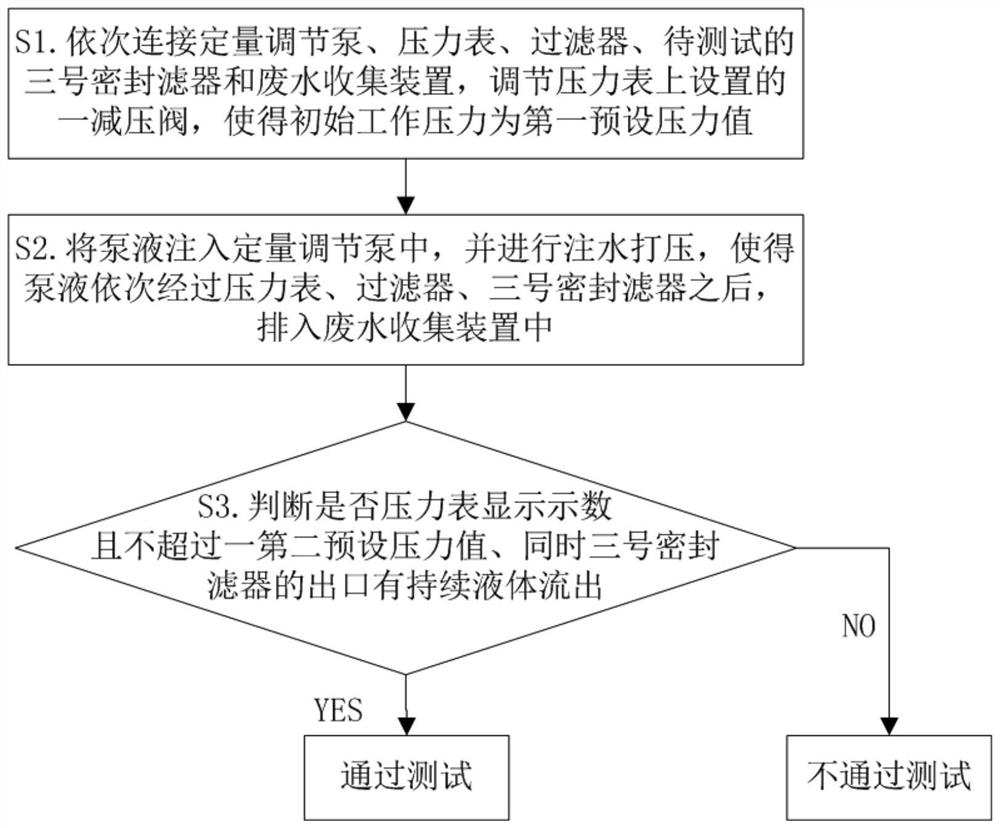

[0036] figure 1 The test device for the No. 3 sealing filter of the main pump in some embodiments of the present invention is shown, which is used for checking the smoothness and continuity of water injection on the installed No. 3 sealing filter of the main pump. The No. 3 sealing filter test device of the main pump in the embodiment of the present invention includes a quantitative adjustment pump 10, a pressure gauge 20, a filter 30, a No. 3 sealing filter 40 and a wastewater collection device 50, wherein the quantitative adjustment pump 10 is used to inject pump liquid And manual pressing, the pressure gauge 20 is used to test the real-time working pressure on the pipeline and is displayed through the pressure gauge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com